Comb-shaped bridge expansion joint plate structure and its cleaning device

A cleaning device and technology for expansion joints, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as vehicle tire damage, bridge body damage, and difficulty in replacement, reduce the risk of extrusion collisions, and prevent beams from over-displacement Great, reduce the effect of tire damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

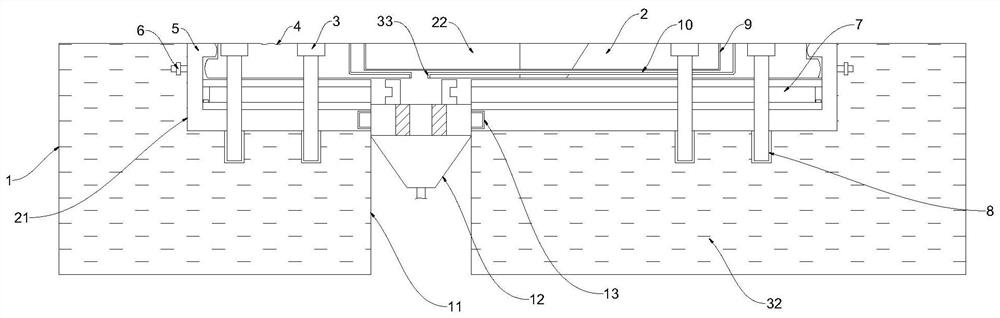

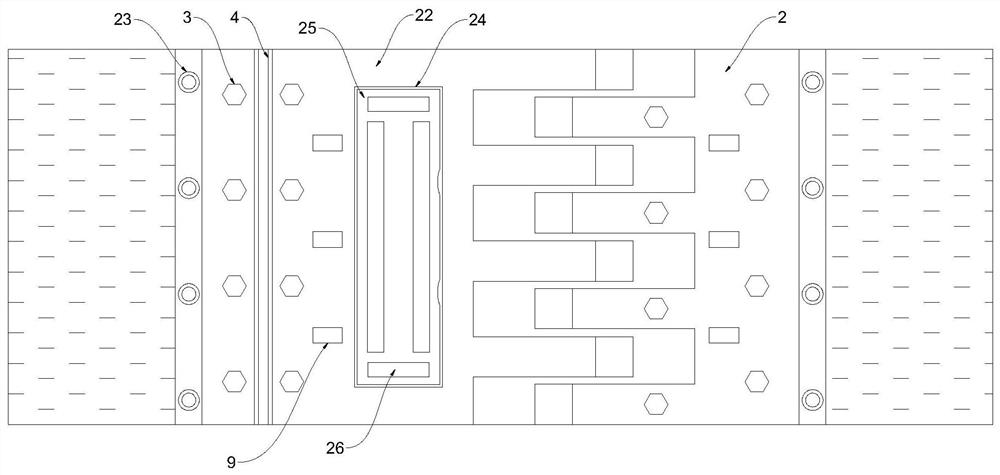

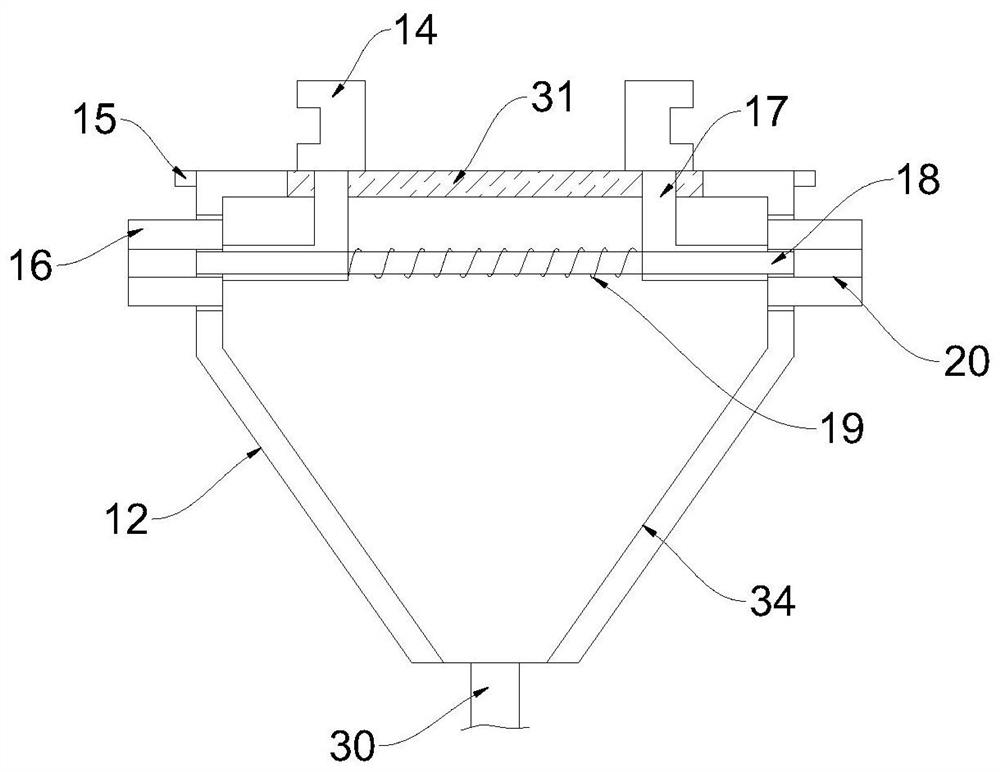

[0035] Such as Figure 1-5As shown, a comb-shaped bridge expansion joint plate structure and its cleaning device include: a first beam body 1, and a second beam body 32 arranged on one side of the first beam body 1, the first beam body The interior of the body 1 and the second beam body 32 is provided with a reserved groove 21, and an expansion joint 11 is provided between the first beam body 1 and the second beam body 32; the comb plate supporting plate 5 is arranged on the Inside the reserved groove 21, the comb-tooth plate supporting plate 5 is fixedly connected with the first beam body 1 and the second beam body 32 through fixing rivets 6; the first comb-tooth type expansion joint plate 22 is arranged on the The inside of the comb-tooth plate supporting plate 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com