A concrete pouring mechanism

A technology for concrete and mixing tank, which is applied in the construction of buildings, construction, and construction materials, etc., can solve the problems of unreachable working radius of concrete pumping, time-consuming and laborious operation of concrete, etc., and achieves easy control and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

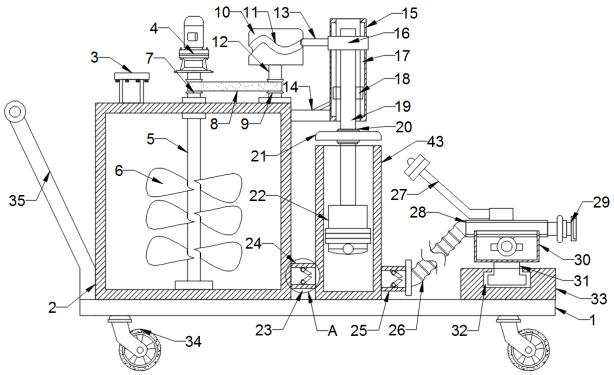

[0027] refer to Figure 1-7, including a base 1, the top side of the base 1 is fixedly connected with a stirring box 2, and the bottom of the stirring box 2 is fixedly connected with the top of the base 1, and the top of the stirring box 2 is fixedly connected with a drive motor 4 through bolts, and the stirring box 2 The inner cavity is provided with a stirring rod 5, and the outer wall of the stirring rod 5 is fixedly connected with several stirring blades 6, the top of the stirring rod 5 runs through the top of the stirring box 2 through a bearing sleeve, and the extension part of the stirring rod 5 is sleeved with a first pulley 7. The output shaft of the drive motor 4 is connected to the top of the stirring rod 5 by transmission. The bottom end of the stirring rod 5 is rotationally connected to the bottom of the inner cavity of the stirring box 2 through a rotating shaft. One side of the stirring box 2 is provided with an extrusion pipe 43, and the The bottom end of the o...

Embodiment 2

[0029] refer to figure 1 with 5 -7, the top of the mixing box 2 is provided with a first rotating rod 12, and the second pulley 9 is sleeved on the first rotating rod 12, and the second pulley 9 and the first pulley 7 are wound and connected by a belt 8, the first The bottom end of the rotating rod 12 is rotationally connected to the top of the mixing box 2 through a rotating shaft, and the top of the first rotating rod 12 is fixedly connected with a cylindrical block 10, and the side of the outer wall of the mixing box 2 close to the extrusion pipe 43 is fixedly connected with a support plate 14 , the side of the support plate 14 close to the extrusion pipe 43 is fixedly connected with a slide plate 15, the inside of the slide plate 15 is provided with a slide bar 19, and both sides of the slide bar 19 are fixedly connected with a slide block 18, and the slide block 18 passes through the slide rail 17 Slidingly connected with the inner wall of the slide plate 15, the inner c...

Embodiment 3

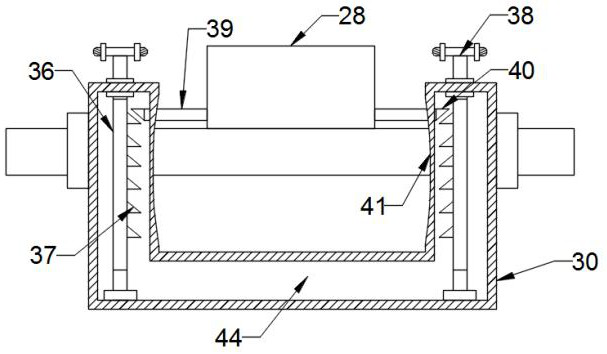

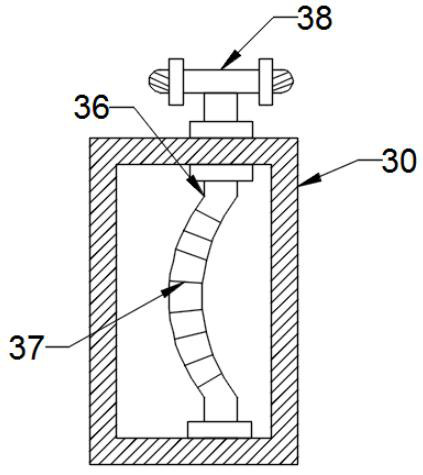

[0031] refer to Figure 1-4 , the inside of the U-shaped plate 30 is provided with an operating cavity 44, the inner cavity of the operating cavity 44 is provided with a second rotating rod 36 on both sides, and the middle part of the second rotating rod 36 is an arc structure, and the bottom of the second rotating rod 36 The end is rotationally connected between the bottom of the operating chamber 44 and the operating chamber through a rotating shaft, and the top of the second rotating rod 36 runs through the top of the vertical section of the U-shaped plate 30 through a bearing sleeve, and the extension end of the second rotating rod 36 is fixedly connected with The handle 38 and the connecting pipe 28 are fixedly connected to the limiting plate 39 on both sides near the inner wall of the U-shaped plate 30, and the end of the limiting plate 39 away from the connecting pipe 28 runs through the inner wall of the U-shaped plate 30 through the notch 41, and the limiting plate 39 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com