Rotor type Stirling refrigerator and working method

A refrigerator and rotor-type technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as difficult to increase the input power of the body, vibration of the whole machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

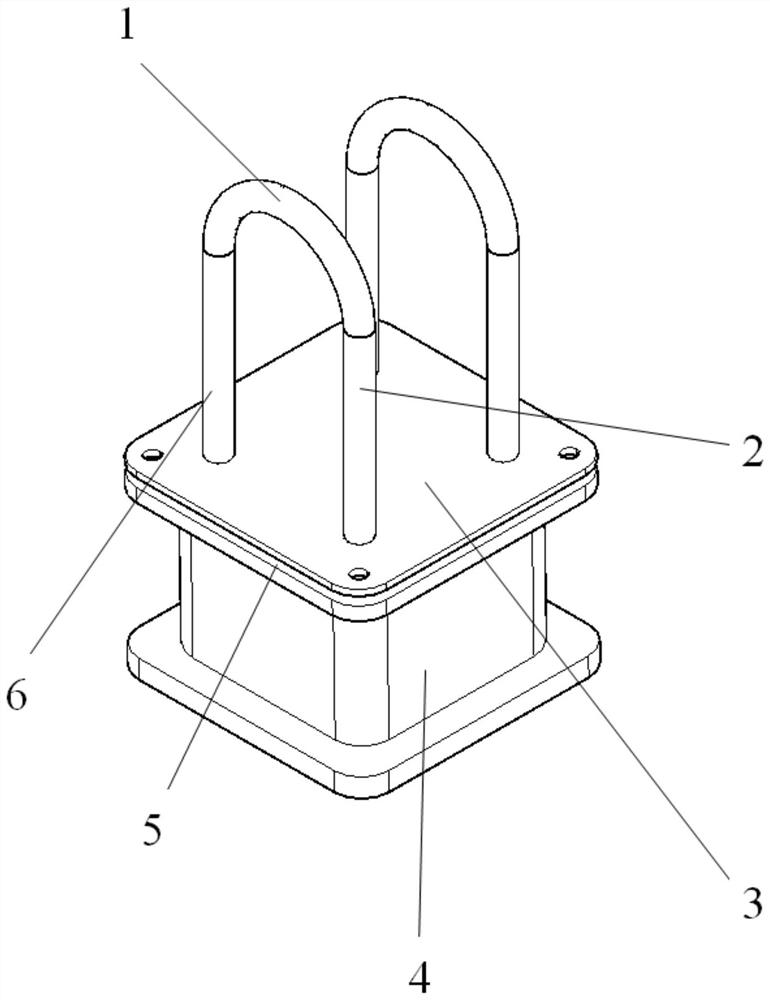

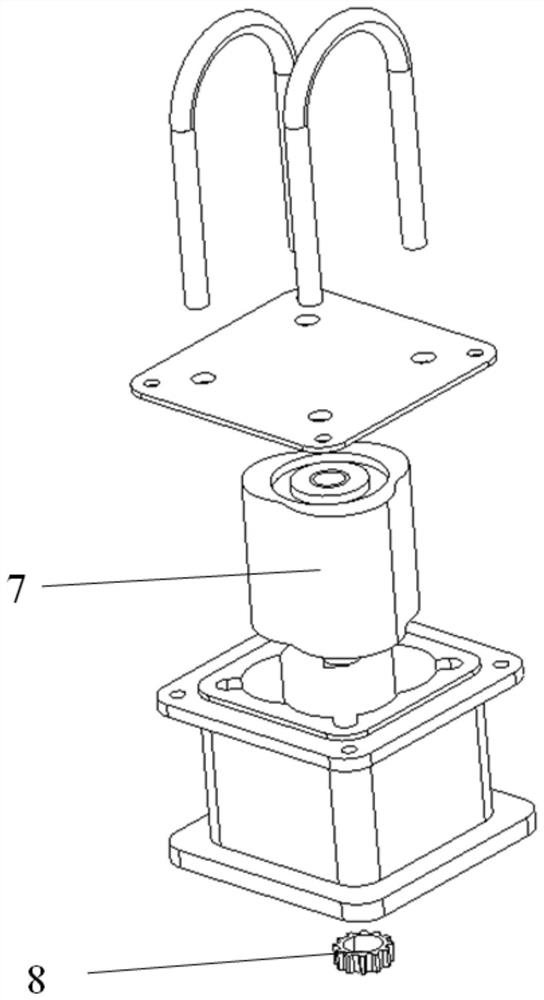

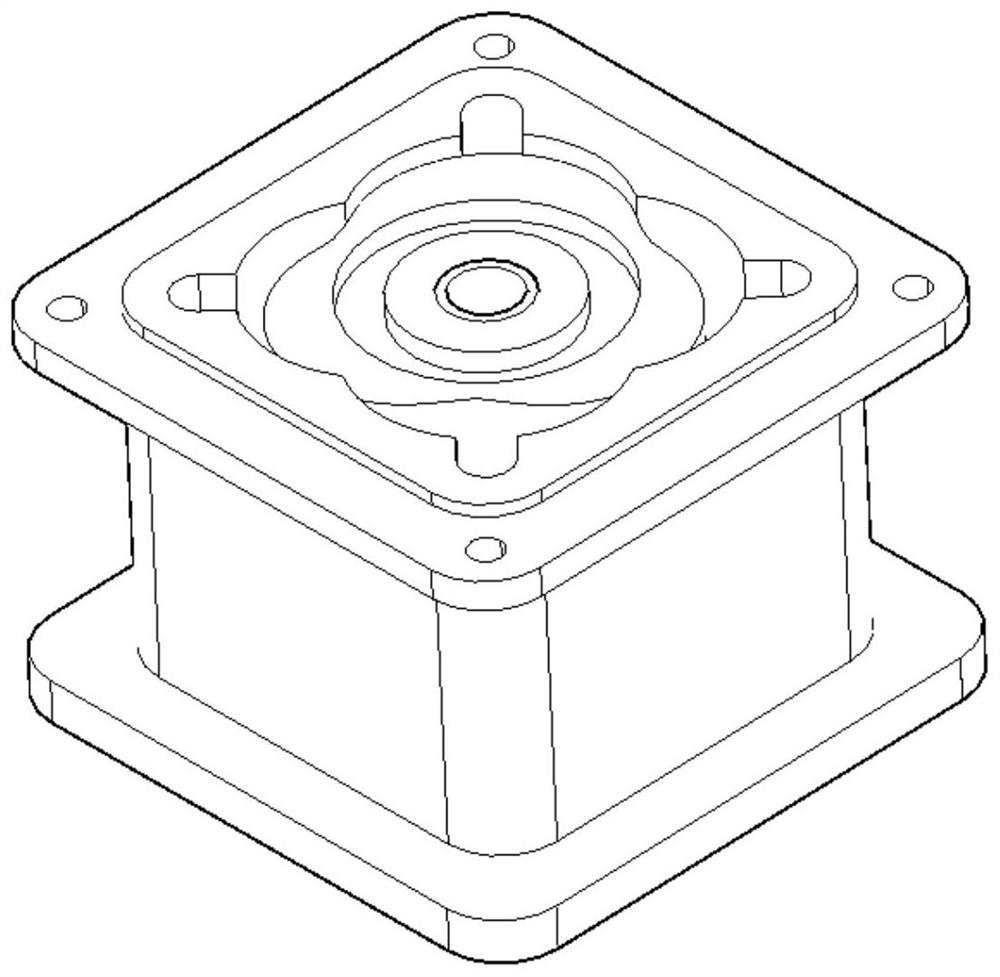

[0034] Such as figure 1 and figure 2 As shown, the rotor-type Stirling refrigerator of the present invention is characterized in that it includes a special-shaped triangular rotor 7, and the special-shaped triangular rotor 7 is arranged in the rotor housing chamber 4, and the rotor housing chamber 4 is provided with a special-shaped triangular rotor 7 In the rotating space, the top of the rotor housing chamber 4 is flanged with an embedded sealing end cover 3, and the bottom is opened with a hole allowing the special-shaped triangular rotor 7 to communicate with the outside world, and the embedded sealing end cover 3 and the space for accommodating the special-shaped triangular rotor 7 At the joint, there is a protrusion matching the rotating space interface. At the same time, there is a sealing rubber ring 5 between the in-type sealing end cover 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com