Method and system for determining electrical load adjustment interval of low-vacuum heat supply unit

A technology for heating units and adjusting intervals, which is applied in the directions of instruments, data processing applications, resources, etc., can solve the problems of complicated calculation, small variation range of electric load, and many parameters, and achieves guaranteed calculation results, less calculation parameters, and improved calculation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

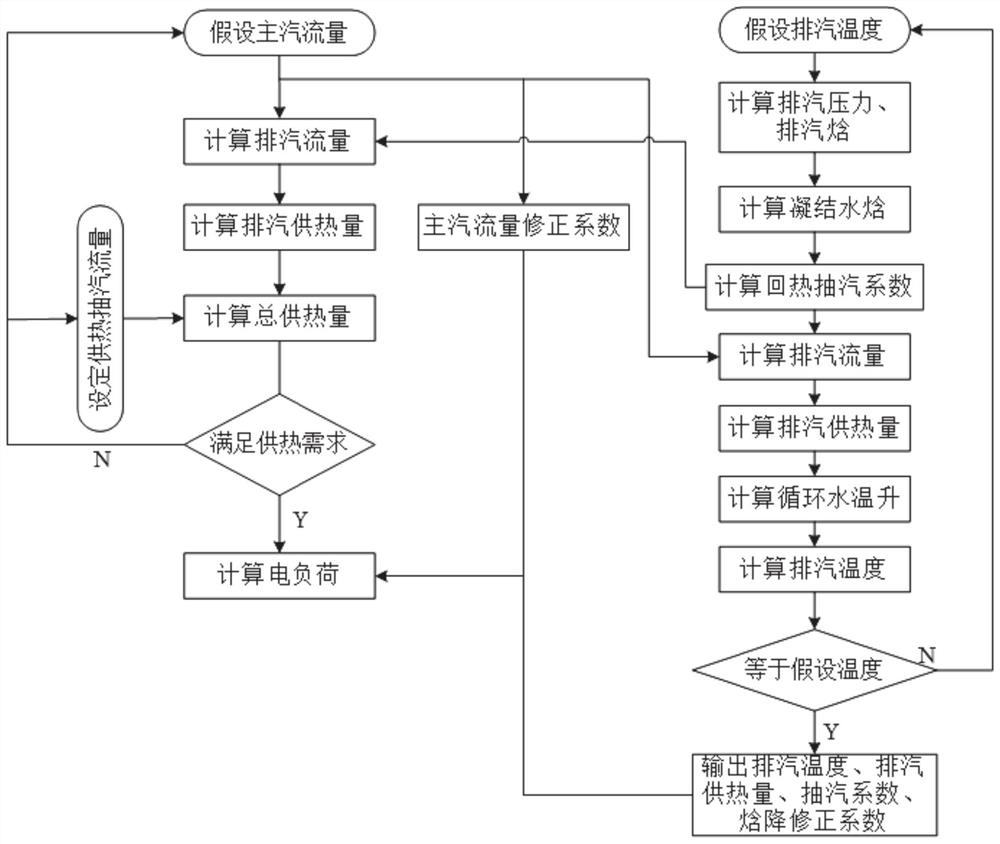

[0035] Such as figure 1 As shown, Embodiment 1 of the present disclosure provides a method for determining the electric load adjustment interval of a low-vacuum heating unit, including the following steps:

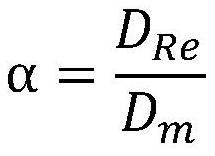

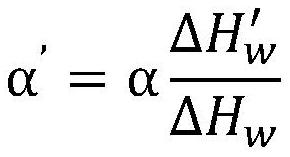

[0036] According to the preset main steam flow and the main steam flow under the reference condition, the main steam flow correction coefficient is obtained, and the enthalpy drop correction coefficient and the regenerative steam extraction coefficient are obtained by iteration according to the exhaust steam parameter data;

[0037] According to the regenerative steam extraction coefficient, the preset main steam flow rate and the preset heating extraction steam flow rate, the total heat supply of the current working condition is obtained;

[0038] When the total heat supply of the current working condition is greater than the preset heating demand, the electric load is obtained according to the obtained main steam flow correction coefficient and steam enthalpy drop correc...

Embodiment 2

[0090] Embodiment 2 of the present disclosure provides a low-vacuum heating unit electric load adjustment interval determination system, including:

[0091] The correction coefficient calculation module is configured to: obtain the main steam flow correction coefficient according to the preset main steam flow and the main steam flow under the reference working condition, and iteratively obtain the enthalpy drop correction coefficient and the regenerative steam extraction coefficient according to the exhaust steam parameter data;

[0092] The total heat supply calculation module is configured to: obtain the total heat supply of the current working condition according to the regenerative steam extraction coefficient, the preset main steam flow rate and the preset heating extraction steam flow rate;

[0093] The electrical load calculation module is configured to: when the total heat supply of the current working condition is greater than the preset heating demand, the electrical ...

Embodiment 3

[0097] Embodiment 3 of the present disclosure provides a medium on which a program is stored. When the program is executed by a processor, the steps in the method for determining the electric load adjustment interval of a low-vacuum heating unit as described in Embodiment 1 of the present disclosure are implemented. The above steps are:

[0098] According to the preset main steam flow and the main steam flow under the reference condition, the main steam flow correction coefficient is obtained, and the enthalpy drop correction coefficient and the regenerative steam extraction coefficient are obtained by iteration according to the exhaust steam parameter data;

[0099] According to the regenerative steam extraction coefficient, the preset main steam flow rate and the preset heating extraction steam flow rate, the total heat supply of the current working condition is obtained;

[0100] When the total heat supply of the current working condition is greater than the preset heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com