Bidirectional stacked high-current plug terminal and connector with same

A plug-in terminal and high-current technology, which is applied to contact parts and other directions, can solve the problems of poor electrical conductivity, weak current-carrying capacity, and fewer contact points for contact connection, and achieve a small overall structure, increased contact area, and increased The effect of touchpoints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described in conjunction with the following examples.

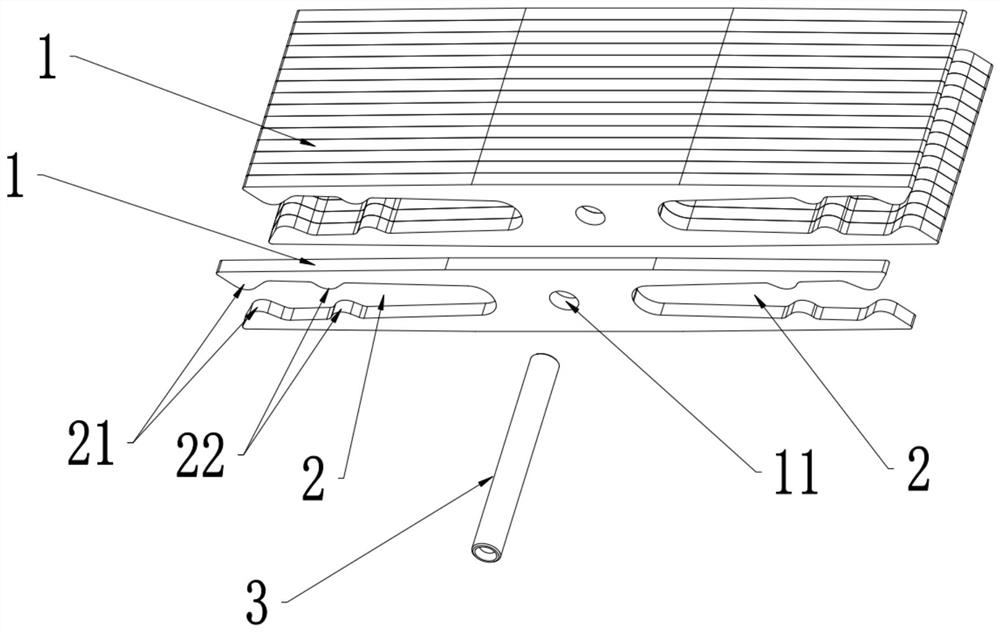

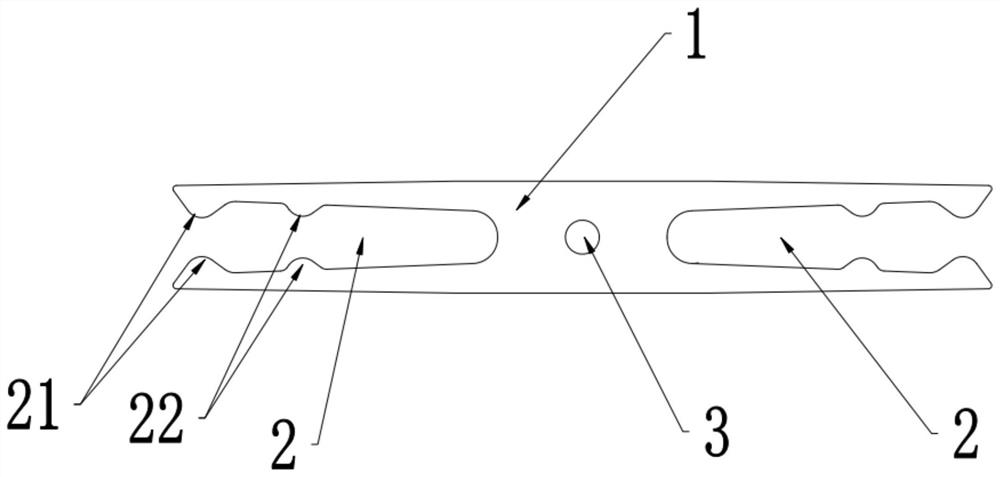

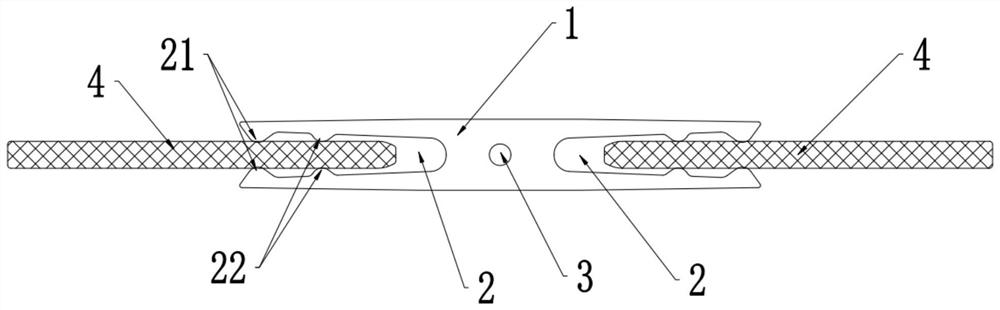

[0028] A specific embodiment of a bidirectional stacked high-current plug-in terminal of the present invention, such as Figure 1-Figure 3 As shown, its structure includes a plurality of terminal grids 1 that are stacked and fixed together, each terminal grid 1 is in the shape of a flat sheet, and each terminal grid 1 is provided with a flat U-shaped plug connector at both ends. Slot 2, the inner side wall of each insertion slot 2 is provided with at least one contact 21, 22 protruding into the slot. . The insertion slot 2 inserts the insert 4, and the contacts 21 and 22 of each insertion slot 2 are in contact with the insert 4, which not only realizes the two-way insertion of the insertion end, but also increases the contact points of the insertion terminal, thereby increasing The large contact area makes the plug terminal have strong current-carrying capacity, low temperature ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com