Rotary-cut turnover type green manure turning device for fruit planting

A flip-over and greening technology, applied in fertilization devices, planting methods, applications, etc., can solve the problems of inability to locally regulate the width of greening, low versatility, and poor greening coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

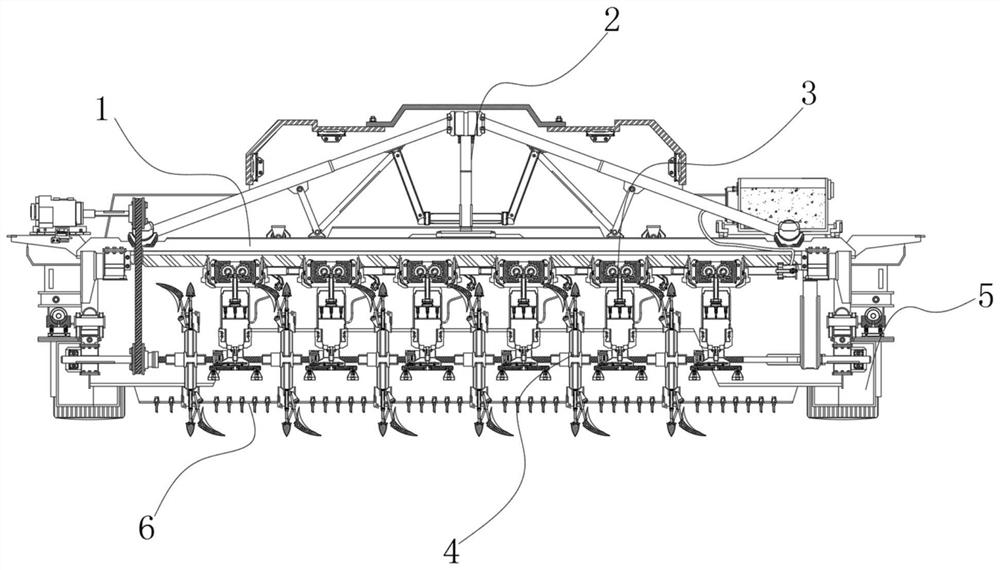

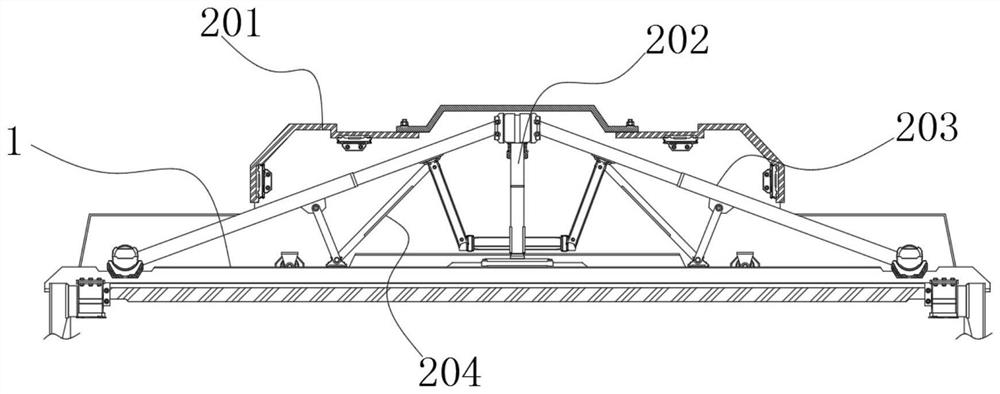

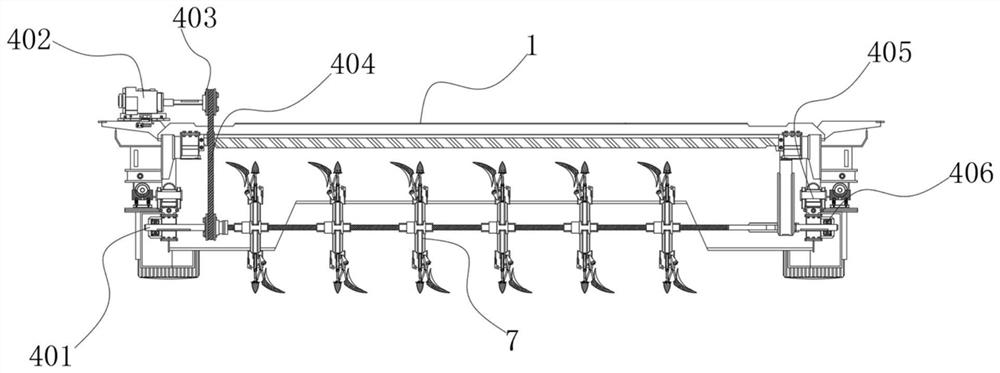

[0033] refer to figure 1 , the present invention provides a technical solution: a rotary cutting and flipping green manure turning green device for fruit planting, which includes a main installation frame 1, an outer driving wheel 5, an upper fixing frame 2, a turning green component 4, and a feeding component 3 and the re-tilling device 6, wherein, the left and right sides of the main installation frame 1 are symmetrically fixed with outer driving wheels 5, and the driving work is carried out on the planting ground through the outer driving wheels 5, and the main installation frame 1 The upper end surface of the main installation frame 1 is provided with an upper fixed frame 2, one end of the upper fixed frame 2 is fixed to the peripheral drive vehicle, and the lower end front side of the main installation frame 1 is provided with a turn green component 4 that can rotate relatively;

[0034] The greening component 4 partially turns the outer layer of the planting ground so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com