Metal waste crushing and recycling device

A recovery device and waste technology, which is applied in the field of metal waste crushing and recycling devices, can solve the problems of insufficient fineness, material jamming and crushing, etc., and achieve the effect of thorough crushing and slow down the falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

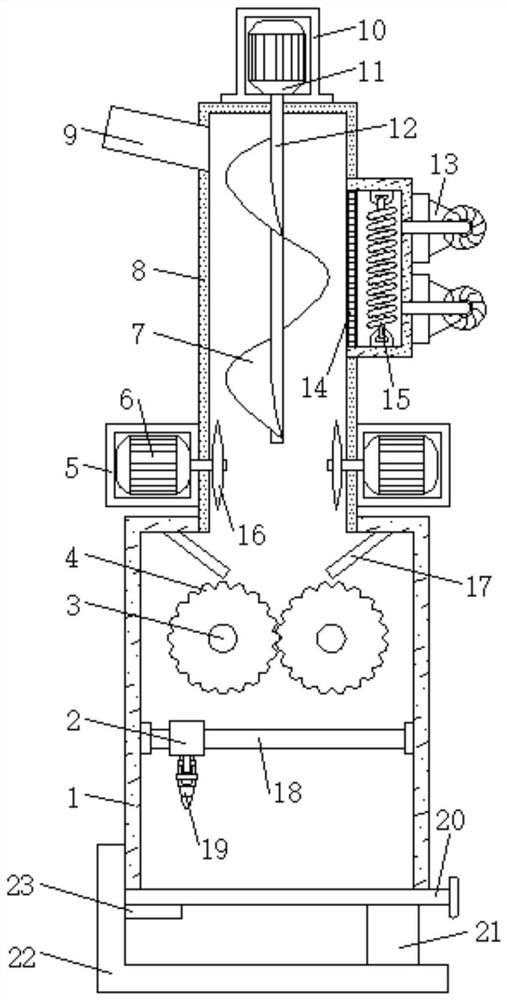

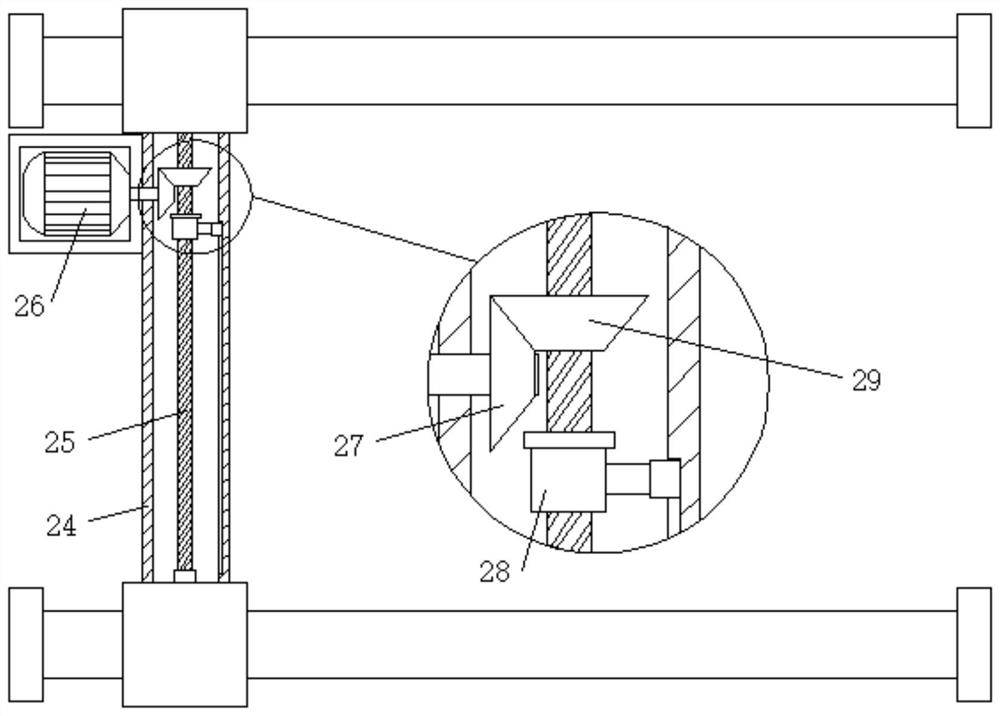

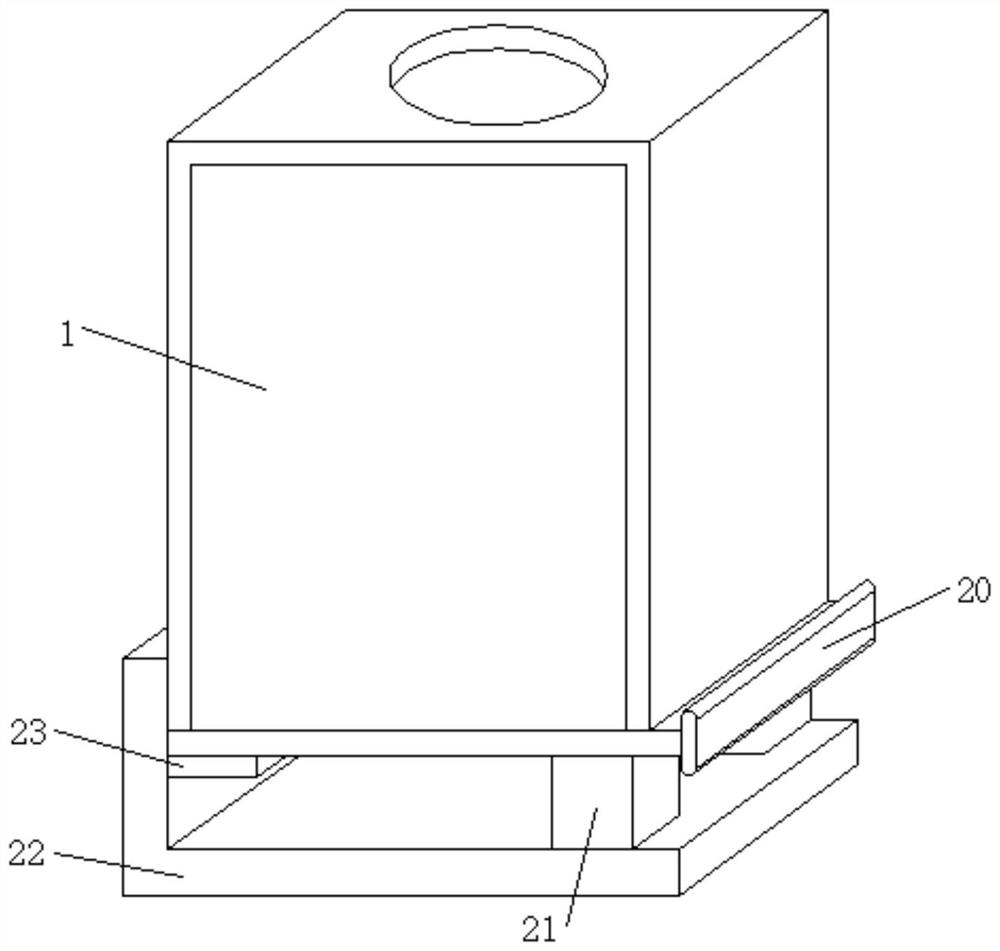

[0025] refer to Figure 1-3 , a metal waste crushing and recycling device, comprising a crushing box 1, a feeding box 8 is inserted in the middle of the outer wall of the top of the crushing box 1, and a feeding hopper 9 is inserted in a position close to the top of one side of the outer wall of the feeding box 8. The top outer wall of the box 8 is fixed with a motor frame 10 by bolts, the bottom inner wall of the motor frame 10 is provided with a first motor 11, and one end of the output shaft of the first motor 11 is keyed to a drive shaft 12, and one end of the drive shaft 12 is located at the feeding Inside the box 8, a screw feeding tray 7 is fixedly connected to the peripheral outer wall of the transmission shaft 12, a drying mechanism is provided on one side of the outer wall of the feeding box 8, and a cutting mechanism is provided on the outer wall of the feeding box 8 on both sides close to the crushing box 1. The outer wall of one side of the crushing box 1 near the...

Embodiment 2

[0029] refer to Figure 4, a metal waste crushing and recycling device. Compared with Embodiment 1, this embodiment has a smoke concentration sensor 30 fixed on one side of the crushing box 1 by bolts, and an alarm sensor 30 is fixed on one side of the crushing box 1 on the outer wall by bolts. 31, the signal output end of the smoke concentration sensor 30 is connected to the signal input end of the alarm 31 through a signal line.

[0030] During use, the interior of the crushing box 1 is provided with a smoke concentration sensor 30, which can detect the smoke concentration inside the crushing box 1. It is provided with a high critical value. When the relatively large smoke generated inside the crushing box 1 reaches the high critical value, a signal will be output To the alarm 31, thereby causing the alarm 31 to report to the police, reminding the staff to come and deal with it, so as to avoid further expansion of the problem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com