Ultrasonic cleaning device

A cleaning device and ultrasonic technology, applied in the field of ultrasonic cleaning, can solve the problems of unreasonable installation location, limited use range, unsatisfactory cleaning effect, etc., and achieve the effects of good safety, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

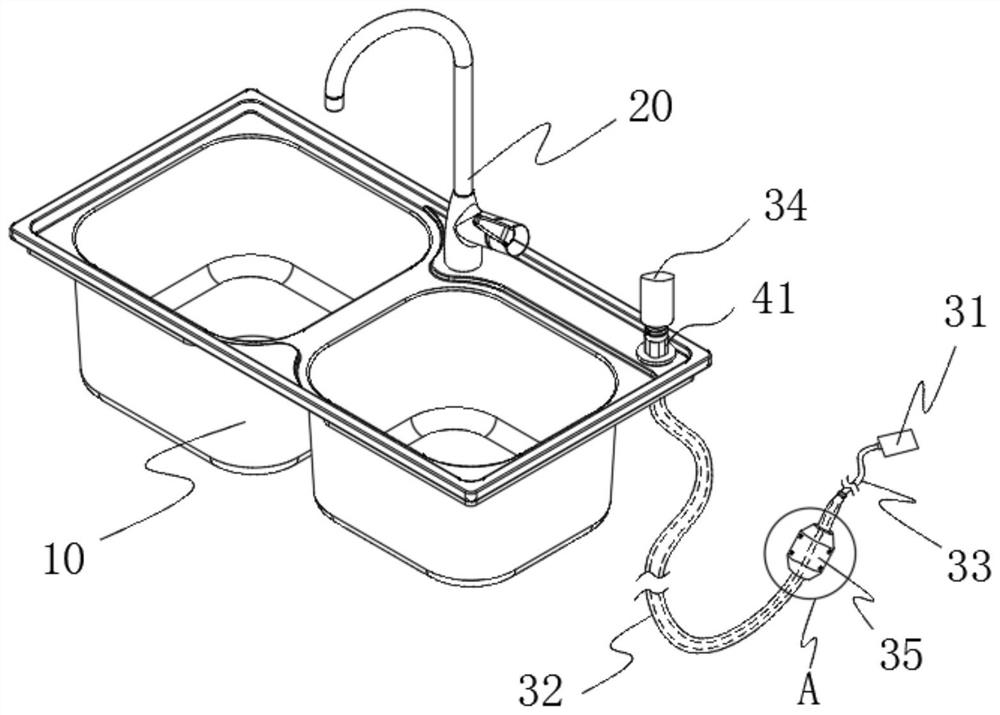

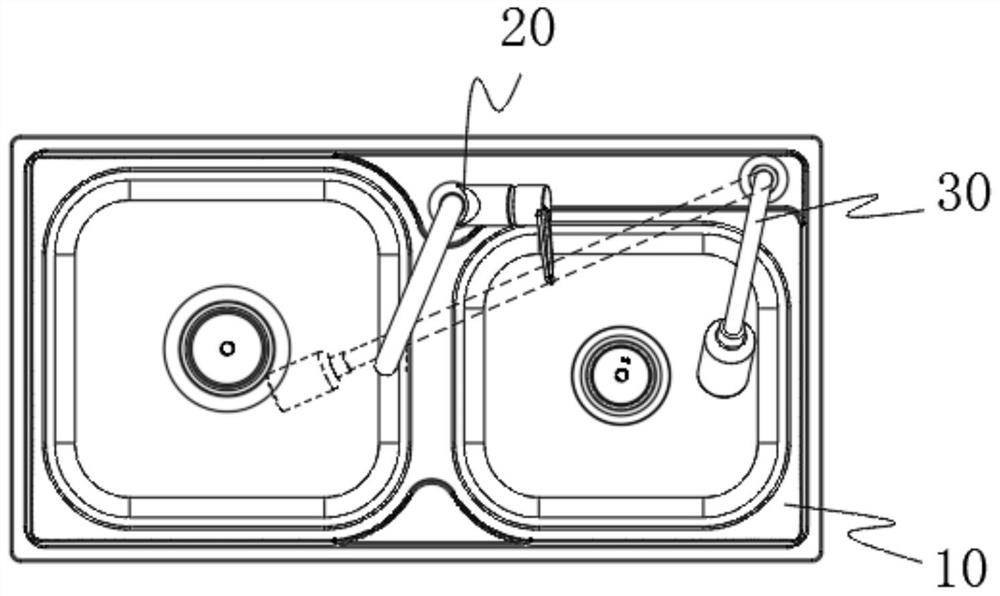

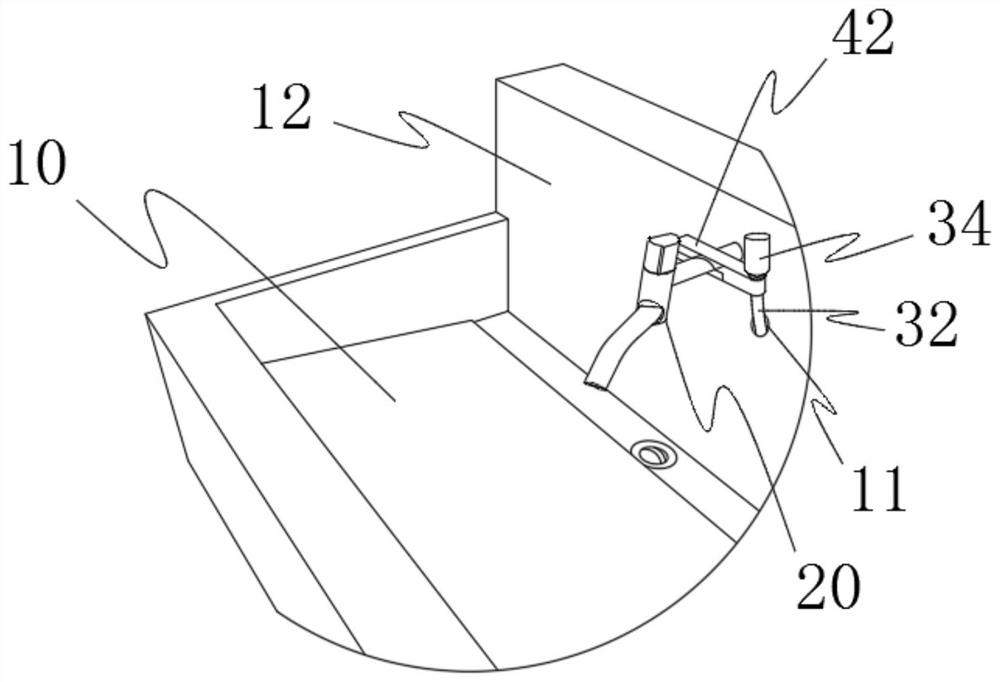

[0026] Such as Figure 1-3 As shown, an ultrasonic cleaning device includes a cleaning tank 10, a faucet 20, an ultrasonic cleaning mechanism 30 and a positioning mechanism. The ultrasonic cleaning mechanism is provided with an ultrasonic generator 31 , a protective sleeve 32 , a counterweight 35 , a wire 33 and an ultrasonic transducer 34 . The cleaning tank 10 is provided with a through hole 11 (not the installation hole of the faucet 20), the inner diameter of the through hole 11 is larger than the outer diameter of the protective sleeve 32, and the protective sleeve 32 is sleeved with a wire 33, and is movable in the through hole 11. The wire 33 The upper end is electrically connected to the ultrasonic transducer 34, the lower end of the wire 33 is electrically connected to the ultrasonic generator 31, the upper end of the protective sleeve 32 is fixedly connected to the ultrasonic transducer 34, and the lower end of the protective sleeve 32 is fixedly connected to the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com