Linear correction method, laser marking equipment and storage medium

A linear correction and laser marking technology, which is applied in the field of laser applications, can solve the problems of large-format platform marking loss accuracy, etc., and achieve the effect of improving the correction speed and marking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

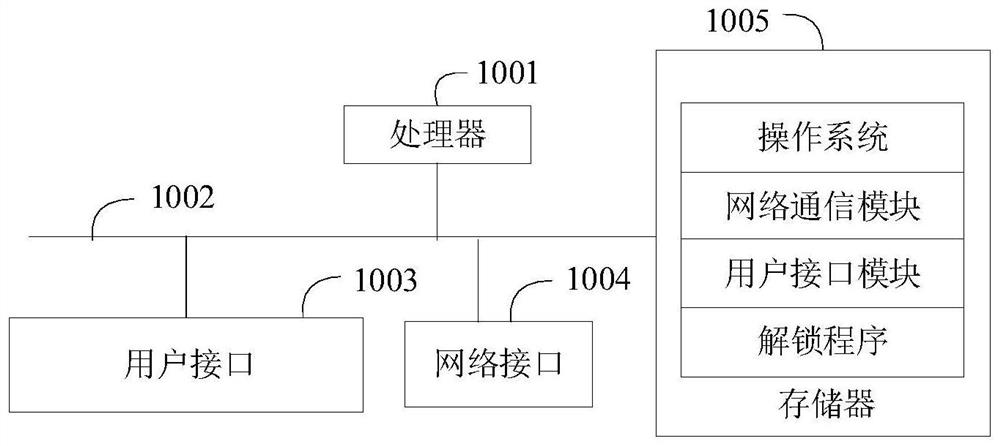

[0037] With the diversification of market demand, laser marking technology is also constantly innovating and developing. With the continuous increase of the marking format, the range of the scanning galvanometer cannot meet the one-time marking requirements, and the XY motion table has become a necessary accessory, and the worktable and the scanning galvanometer will naturally have an angle during the assembly process. If If the angle correction between the worktable and the scanning galvanometer is not carried out, the large-format platform marking will lose accuracy.

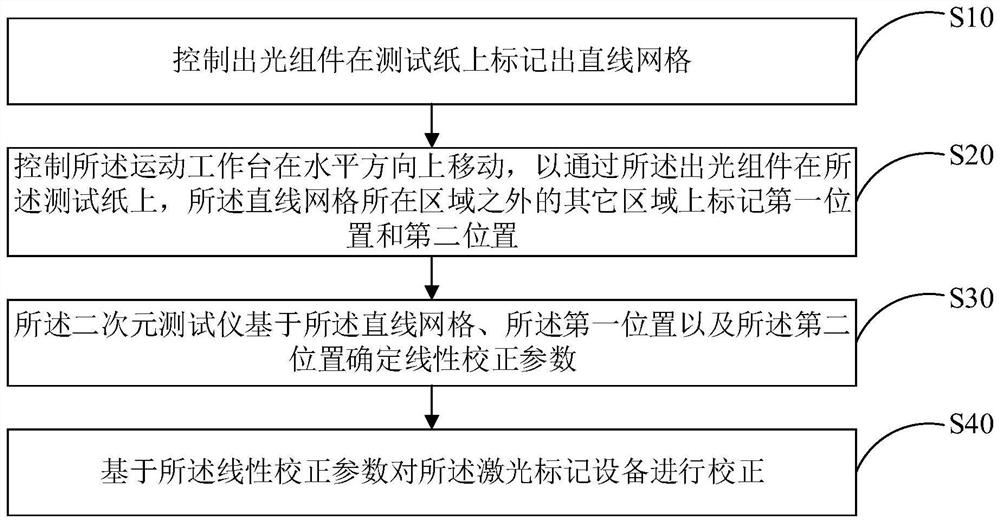

[0038] In order to improve the accuracy of laser marking equipment, an embodiment of the present invention proposes a linear correction method, the main solution of which includes the following steps:

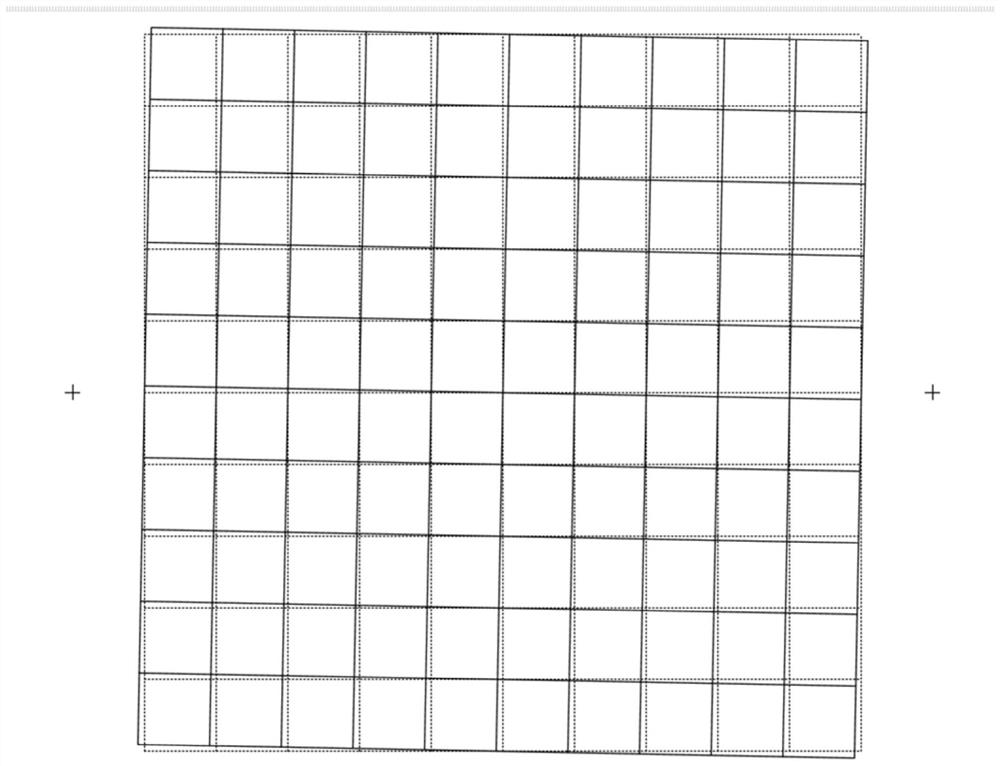

[0039] Control the light-emitting component to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com