Steel bar spacing marking device

A technology for the spacing and punctuation of rebars, which is applied in the field of punctuation devices for rebar spacing, can solve the problems of large influence of surface flatness, poor marking accuracy, inconvenient control and adjustment of spacing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

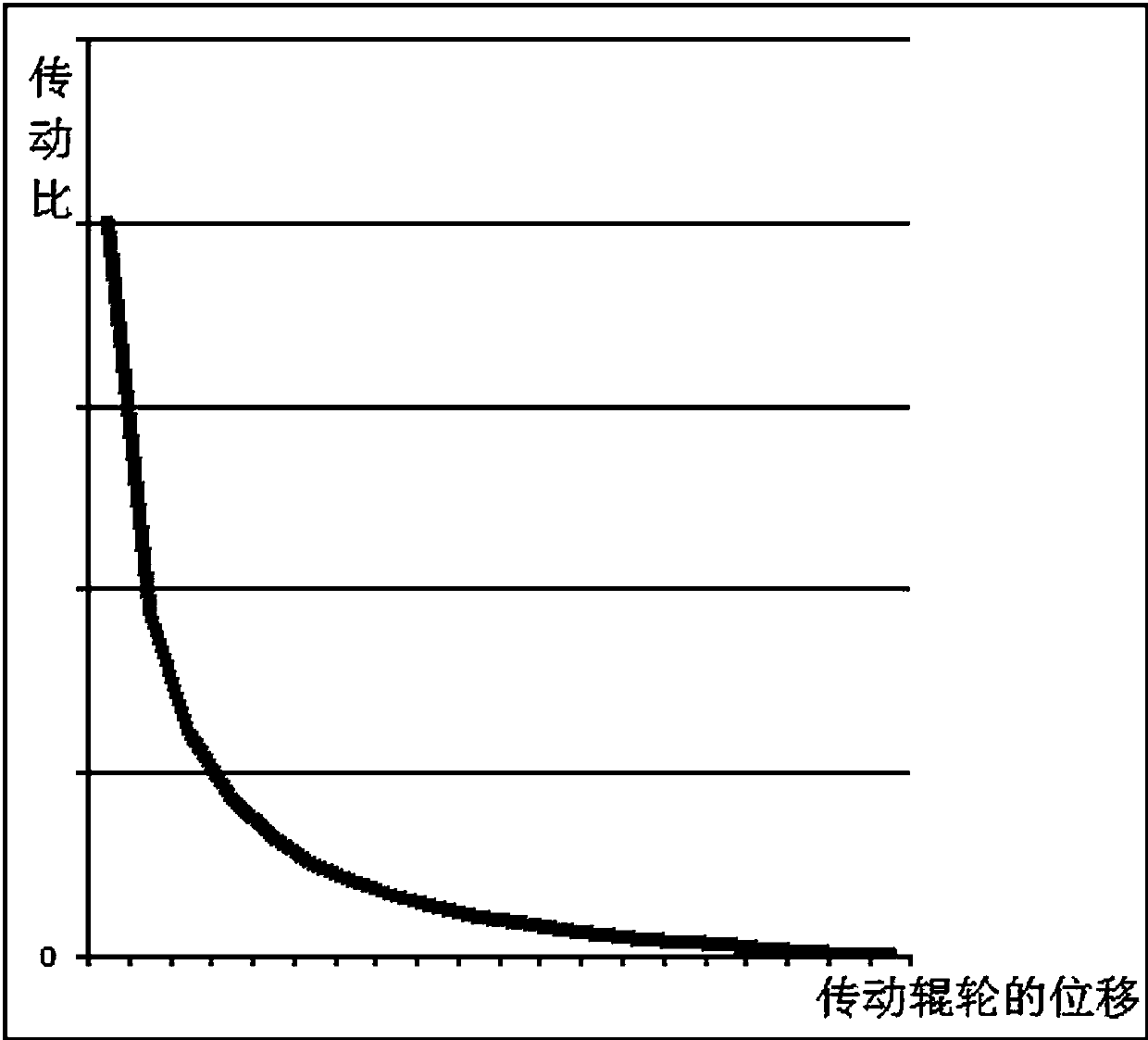

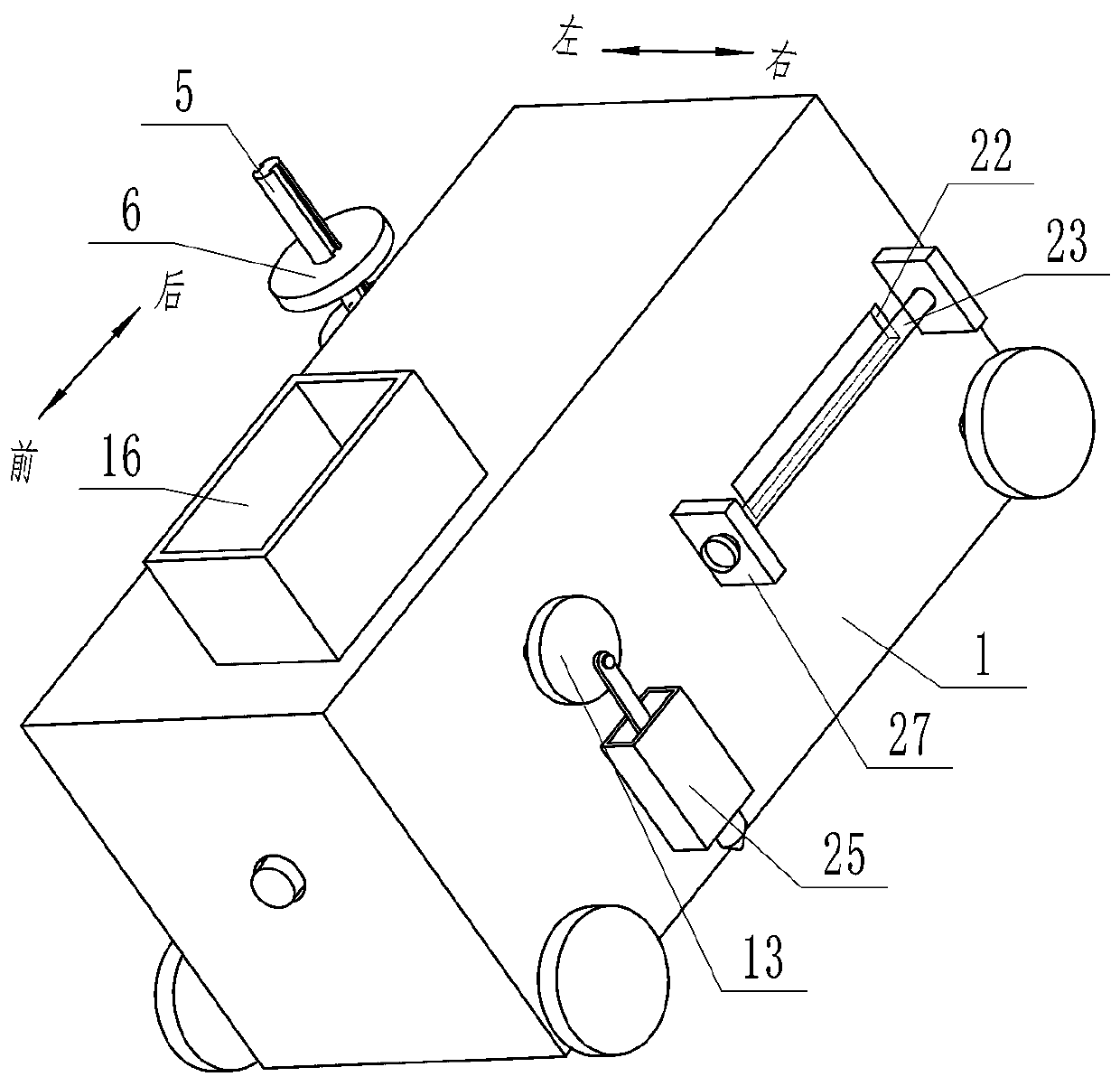

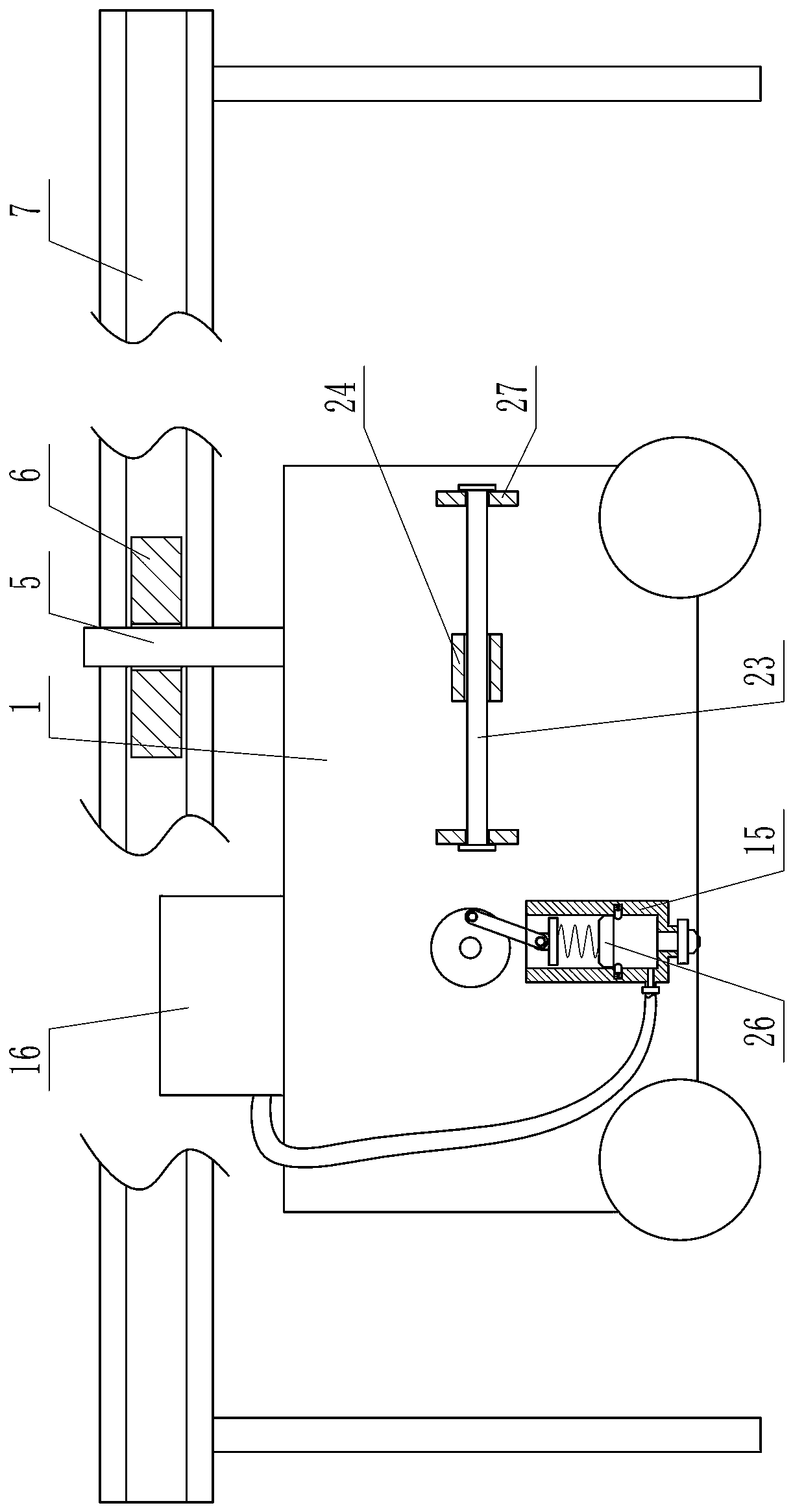

[0018] Depend on Figure 1 to Figure 8 Given, the present invention includes a rectangular housing 1, a horizontal drive shaft 2 that can actively rotate runs through the left side wall of the housing 1, the left end of the driving shaft 2 penetrates the side wall of the housing 1 and is placed outside the housing 1, the active The left end of the shaft 2 is fixed with the first bevel gear 3, the upper side of the first bevel gear 3 is meshed with the horizontal second bevel gear 4, and the upper end of the central axis of the first bevel gear 3 is connected with a spline shaft 5 through a universal coupling , the spline shaft 5 is set with a roller 6 that can move up and down along the spline shaft 5, a slideway 7 parallel to the ground is arranged on one side of the housing 1, the roller 6 can roll along the slideway 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com