Device and method for measuring influence of natural gas hydrate drilling pipeline microbend on flow field

A measuring device and hydrate technology, which is applied in the directions of surveying, earthwork drilling, wellbore/well components, etc., can solve problems such as casing bending, and achieve the effect of strong simulation authenticity, convenient operation and good simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below according to the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the present invention is not limited to the scope of specific implementations. For those of ordinary skill in the art, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, they are all within the scope of protection. List.

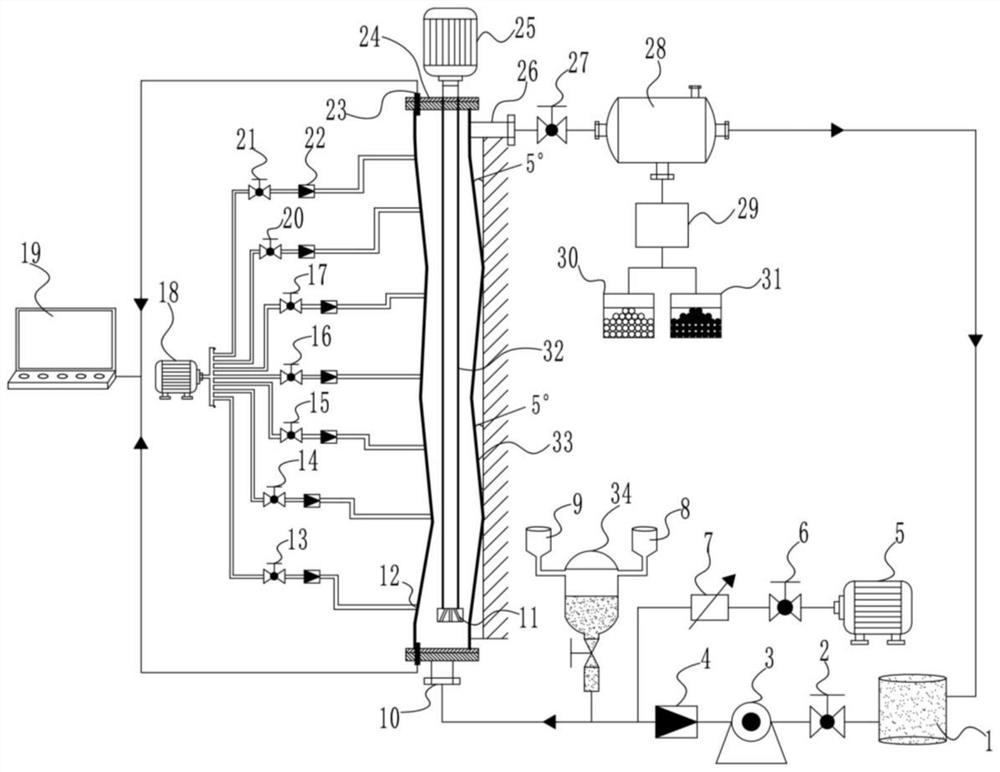

[0029] see figure 1 .

[0030] A measuring device for the influence of microbending of natural gas hydrate drilling pipeline on the flow field, consisting of a driving motor 25, a drill pipe 32, a transparent casing 33, a detachable blind plate 24, a mixing tank 34, a water storage tank 1, a water pump 3, and a liquid flow meter 4. First aeration pump 5, gas flow meter 7, pressure sensor 23, pressure monitoring system 19, second aeration pump 18, three-phase separator 28, elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com