Air-fuel ratio control method and device

A control method and technology of air-fuel ratio, applied in fuel injection control, electrical control, engine control, etc., can solve problems such as engine air-fuel ratio fluctuation, achieve precise air-fuel ratio control, and reduce fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

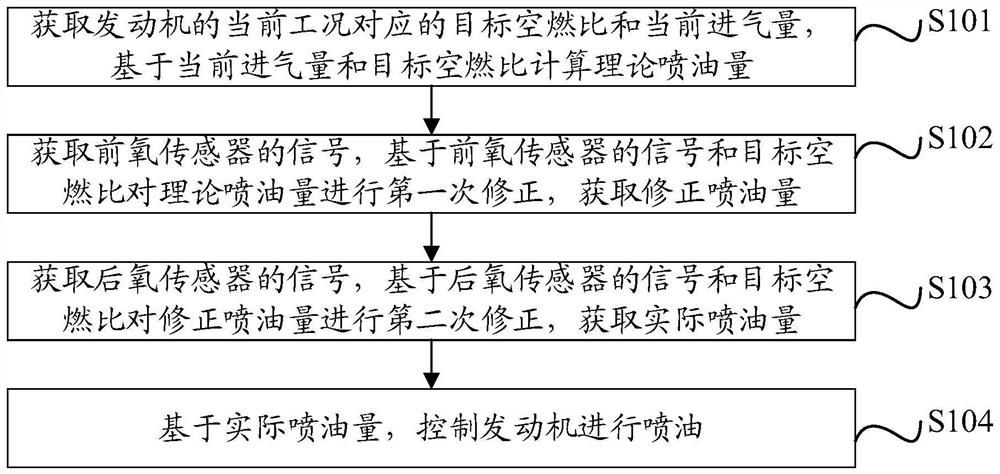

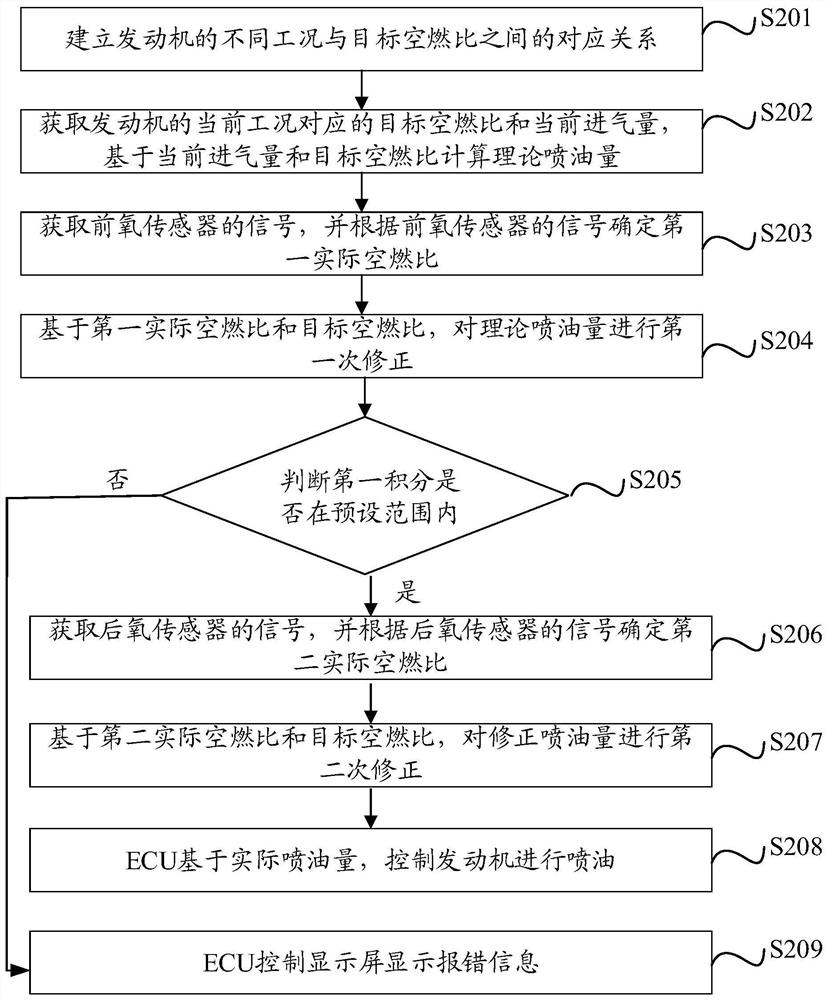

[0055] An embodiment of the present application provides an air-fuel ratio control method, which can be executed by an ECU (Electronic Control Unit, electronic control unit) of a vehicle, such as figure 1 As shown, the air-fuel ratio control method includes the following steps:

[0056] S101. Obtain the target air-fuel ratio and the current intake air volume corresponding to the current working condition of the engine, and calculate the theoretical fuel injection volume based on the current intake air volume and the target air-fuel ratio;

[0057] S102. Obtain the signal of the front oxygen sensor, perform a first correction to the theoretical fuel injection quantity based on the signal of the front oxygen sensor and the target air-fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com