Pump impeller, lye pump, household appliance and method for producing pump impeller

A technology for household appliances and pump impellers, applied in the field of pump impellers, can solve the problems that the necessary operation of the pump cannot be fully ensured, it is no longer possible to achieve, and the pump power is unfavorable, so as to achieve a simple drive speed adjustment device, avoid current peaks, and avoid power effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

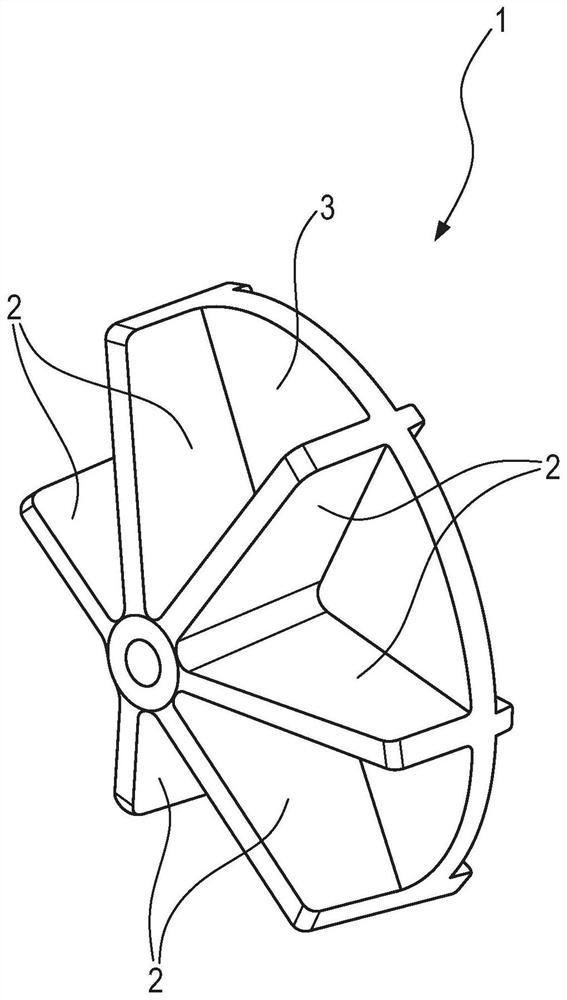

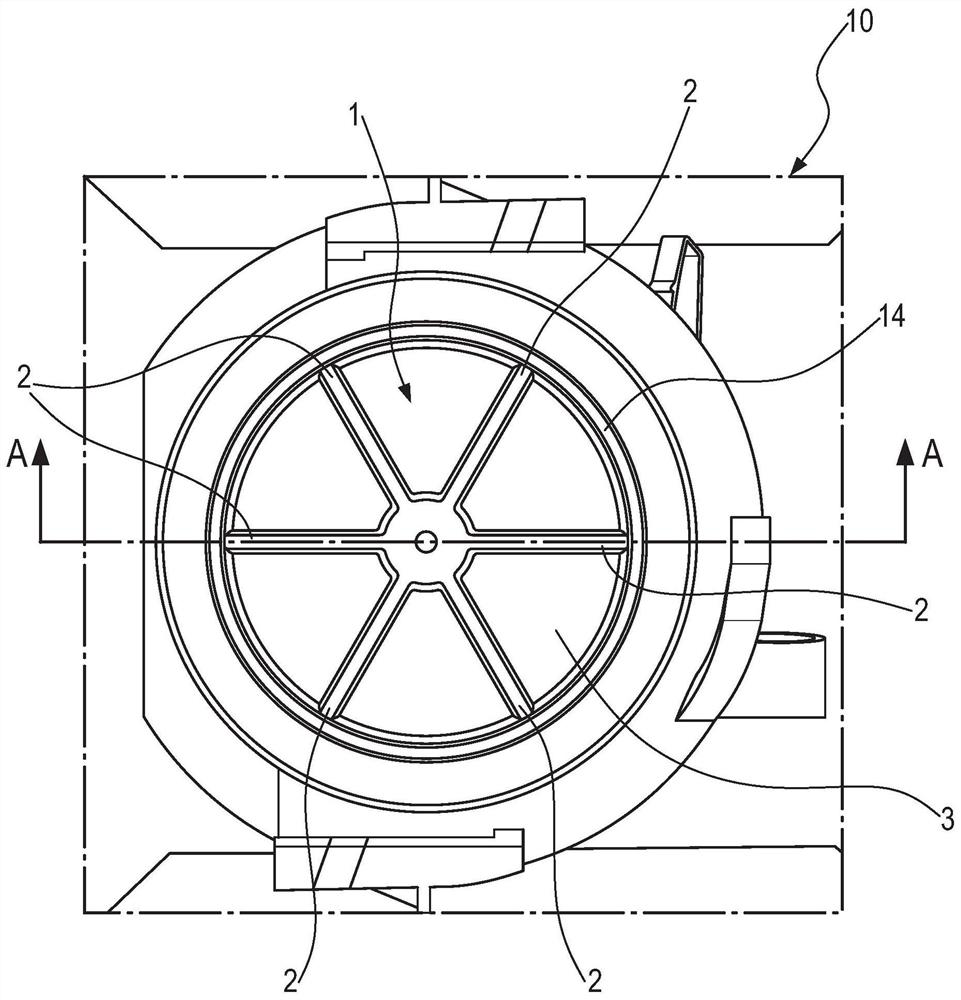

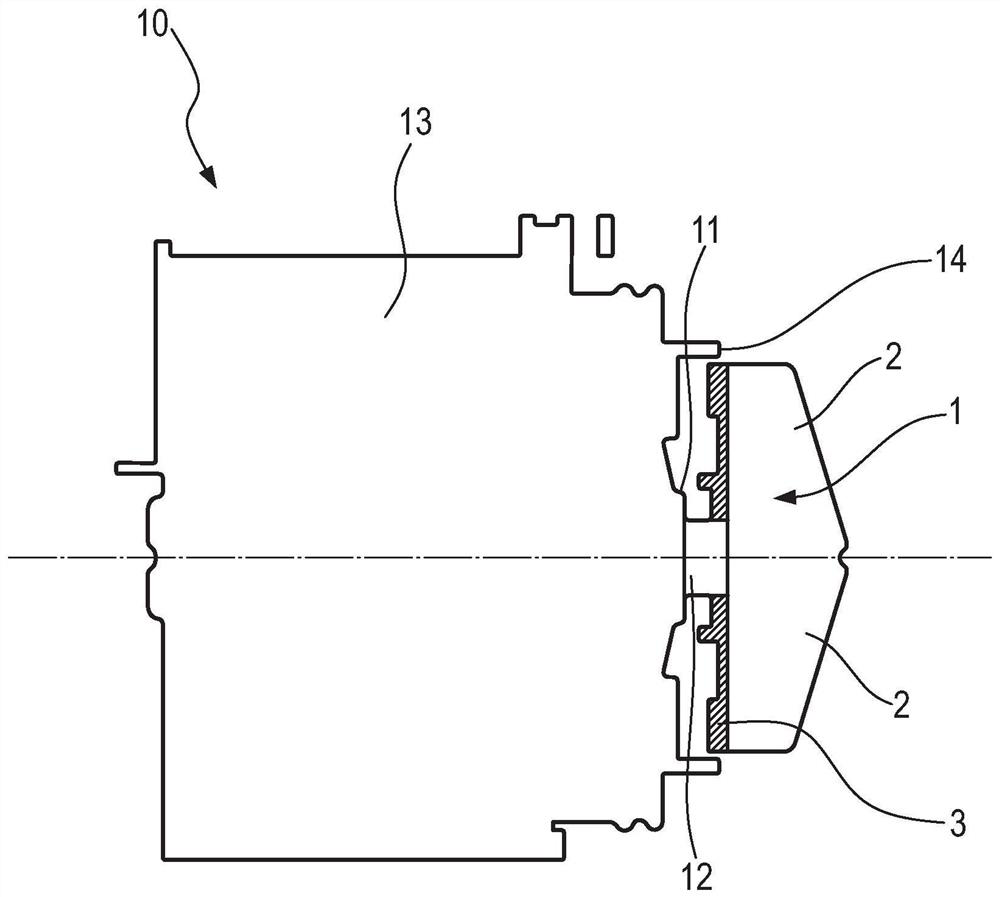

[0041] figure 1 A pump impeller 1 according to an embodiment of the invention is shown. The pump impeller 1 includes a working wheel blade 2 and a working wheel disk 3 . In this case, the rotor blades 2 are arranged on one side of the rotor disk 3 . The impeller blades 2 extend in the radial direction of the impeller disk 3 and at right angles thereto. The present embodiment comprises six impeller blades 2 .

[0042] The pump impeller 1 consists of a base material, that is to say both the impeller blades 2 and the impeller disk 3 consist of a base material. Furthermore, the radially outermost parts of the rotor blades 2 and of the rotor disk 3 (ie the region of the outer edge of the rotor disk 3 between 2 mm and 5 mm) are coated with an outer layer material. The outer material is softer than the base material. According to a further embodiment, the working wheel 3 comprises a circumferential flange which is arranged on the circumferential surface of the working wheel 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com