Invisible tooth socket with traction accessory and manufacturing method of invisible tooth socket

A technology of invisible braces and a manufacturing method, applied in the field of dental instruments, can solve problems such as easy deformation, warping and scratching of oral mucosa, and achieve the effects of not easily deformed and improved comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

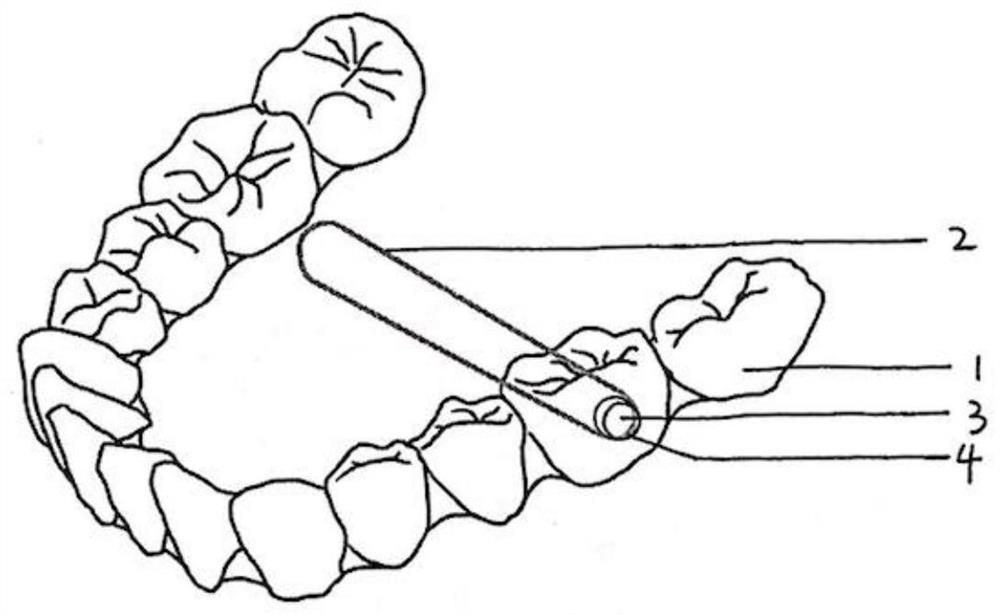

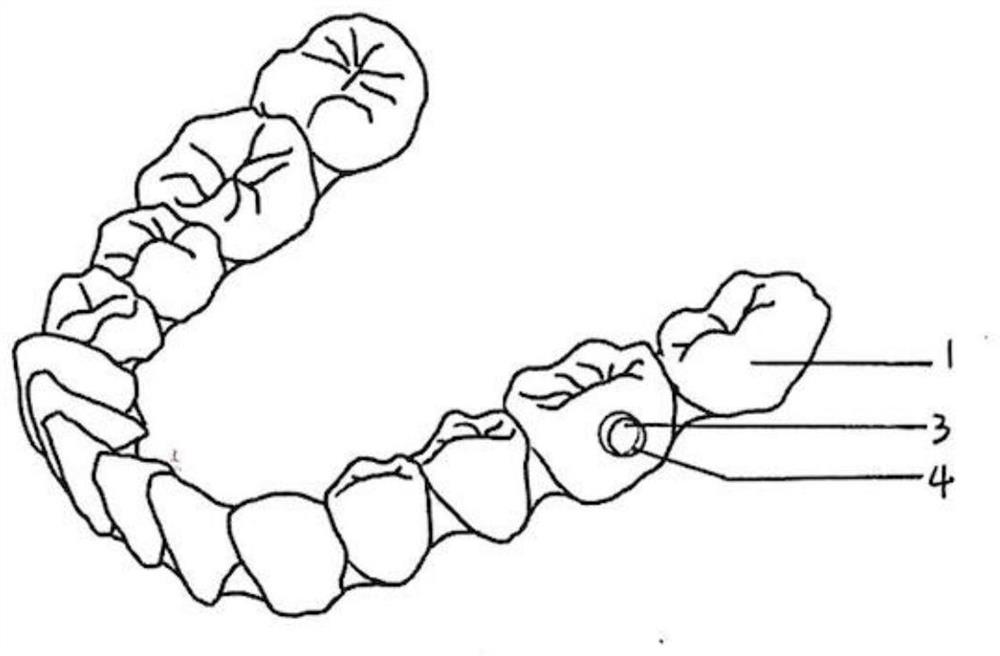

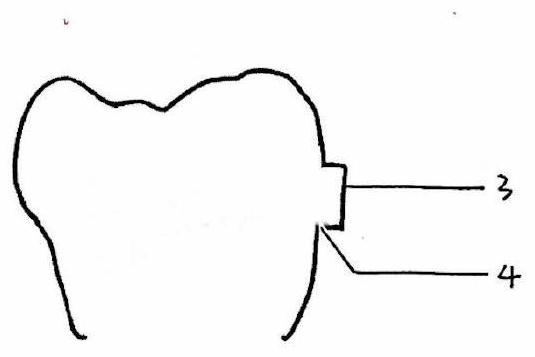

[0030] An invisible brace with traction accessories and a manufacturing method thereof, comprising an invisible brace body (1) and a dynamic rope (2), the brace body (1) is provided with local protrusions (31), (32), The bottom of the protrusion is provided with notches (41), (42) which are cut smoothly, and the accompanying drawing uses two small short lines to mark the start and end points of the notches, and the power rope (2) can be fixed through the notches (41), (42) .

[0031] A local protrusion (31) is provided at the center of the buccal surface of the maxillary canine, and a local protrusion (32) is provided at the center of the buccal surface of the mandibular first molar on the same side.

[0032] Preferably, the partial protrusion may be cylindrical, with a diameter of 4 mm and a height of 2 mm.

[0033] The notch (41) of the maxillary canine is near the mesial side near the gingiva. The gap (42) of the mandibular molars is near the gingiva side and is near the ...

Embodiment 2

[0039] Compared with Example 1, as another embodiment, a local protrusion (31) is provided at the center of the buccal surface of the mandibular canine, and a local protrusion (32) is provided at the center of the buccal surface of the maxillary first molar on the same side. The notch (41) of the mandibular canine is close to the mesial side near the gingiva. The gap (42) of the maxillary molars is near the gingiva and near the distance. The specific implementation is similar to the above example, realizing the common type III traction in orthodontics, providing sufficient anchorage for the mandibular molars backward, and avoiding the stimulation of the oral mucosa by cutting the opening at the edge of the brace.

Embodiment 3

[0041] Compared with Example 1, as another implementation mode, local protrusions (31), (32) are set in the center of the buccal surface of the teeth on both sides of the impacted teeth, and the gaps (41), (42) are all close to the occlusal side. Ambush teeth are affixed with brackets after the operation is exposed, and two dynamic rope one ends are hung on gap (41), (42) respectively, and the other ends are all hung on the brackets of the embedded teeth. The other specific implementations are similar to the above-mentioned examples, which realize the traction of the impacted teeth and avoid the stimulation of the oral mucosa by cutting the openings at the edge of the braces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com