Grinding and sorting equipment for waste buildings and structures

A structure and sorting technology, which is applied in grain processing, separation methods, and dispersed particle separation, etc., can solve the problems of inconvenient collection and cleaning of metal objects, environmental pollution, etc., and achieve the effect of easy cleaning and transportation and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

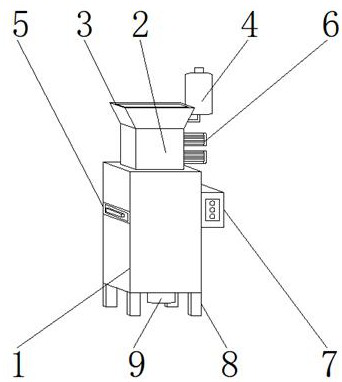

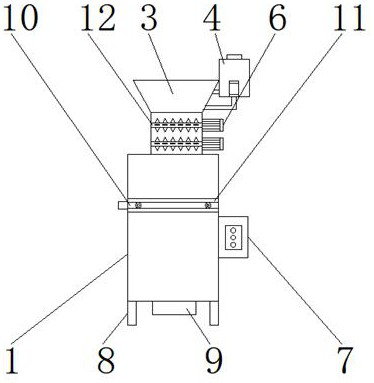

[0018] Example 1 as figure 1 As shown, a kind of crushing and sorting equipment for abandoned building structures includes a main body box 1, a crushing tube 2 is arranged on the outer surface of the upper end of the main body box 1, and a feeding port 3 is provided on the outer surface of the upper end of the crushing tube 2, and the feeding port 3 A dust removal device 4 is provided on one side of the outer surface, a cleaning port 5 is provided on one side of the main body box 1, a servo motor 6 is provided on one side of the crushing tube 2, and a Controller 7, the outer surface of the lower end of the main body box 1 is provided with a bracket 8 and a discharge port 9, the bracket 8 is located around the discharge port 9, the inside of the main body box 1 is provided with a guide rail 10, and the middle part of the guide rail 10 is provided with a sorting In the device 11 , a crushing rod 12 is arranged inside the crushing tube 2 .

Embodiment 2

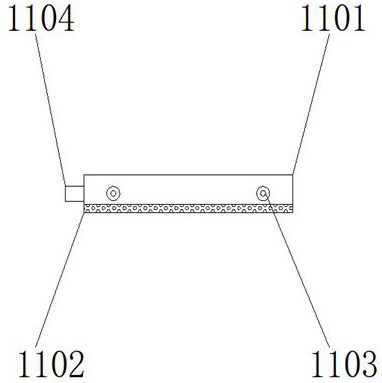

[0019] Embodiment 2 is on the basis of embodiment 1, as image 3 As shown, the sorting device 11 includes a sorting box 1101, a drain plate 1102, a roller 1103 and a handle 1104, the drain plate 1102 is located on the outer surface of the lower end of the sorting box 1101, and the rollers 1103 are located on the outer surfaces of both ends of the sorting box 1101, The handle 1104 is located on the outer surface of one side of the sorting box 1101. The sorting device 11 is beneficial to collect the sorted metal objects during use, which is convenient for cleaning and transportation, and is convenient for further processing of the sorted metal objects during use. processing.

Embodiment 3

[0020] Embodiment 3 is on the basis of embodiment 2, as image 3 As shown, a fixing groove is arranged between the sorting box 1101 and the drain plate 1102, and the outer surface of the lower end of the sorting box 1101 is detachably connected to the upper outer surface of the drain plate 1102 through the fixing groove. A connecting shaft is provided, and the outer surfaces of both ends of the sorting box 1101 are movably connected with the outer surface of one end of the roller 1103 through the connecting shaft. The surface is detachably connected to one side of the outer surface of the pull handle 1104 through Phillips screws. The sorting box 1101 is beneficial to collect the sorted metal objects during use. The roller 1103 is beneficial to make the sorting box 1101 on the guide rail 10 to move in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com