A limit optimization method for a seven-degree-of-freedom manipulator based on position-level inverse kinematics

A technology of inverse kinematics and optimization methods, which is applied to manipulators, program-controlled manipulators, and manufacturing tools. Dynamic self-motion, ensuring consistency, and optimizing the joint range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

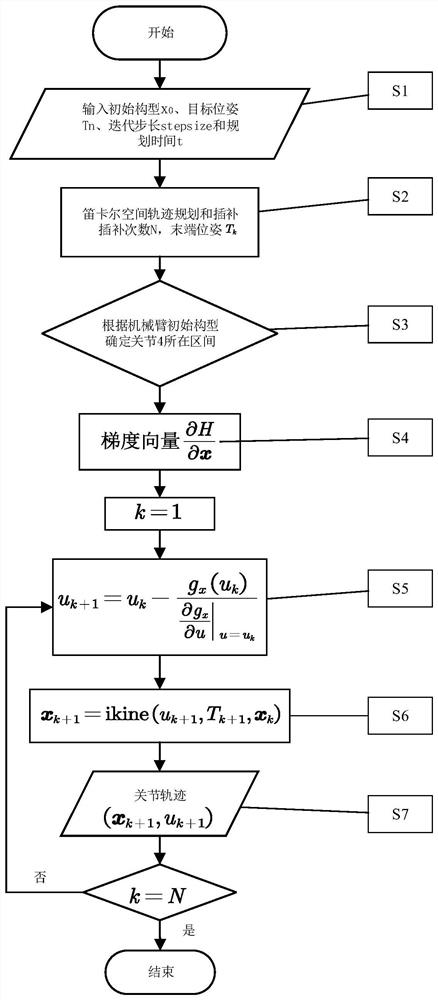

[0054] Specific Embodiment 1: A position-level inverse kinematics-based seven-degree-of-freedom mechanical arm limit optimization method in this embodiment includes the following steps:

[0055] Step 1: Obtain the analytical solution of the inverse kinematics of the seven-degree-of-freedom manipulator based on the parametric solution of a fixed joint angle;

[0056] Step 2: take the fixed joint angle parameter as input, and the joint limit as an optimization index, and establish an optimal control problem;

[0057] Step 3: Transform the constrained problem into an unconstrained problem based on the Lagrange multiplier method;

[0058] Step 4: Realize the solution to the optimal joint angle parameters based on the Newton iterative method;

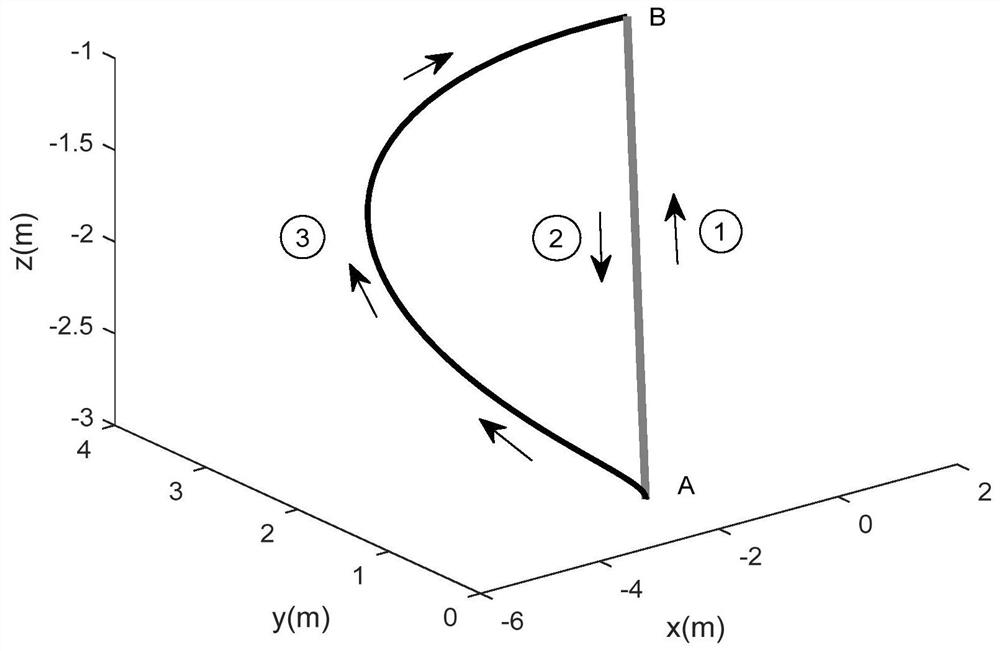

[0059] Step 5: By giving the initial configuration, expected end pose and Cartesian path planning, seven joint space trajectories considering joint limit optimization are obtained.

[0060] The present invention aims at optimizing the para...

specific Embodiment approach 2

[0061] Specific implementation mode two: step one of this embodiment mode comprises the following steps:

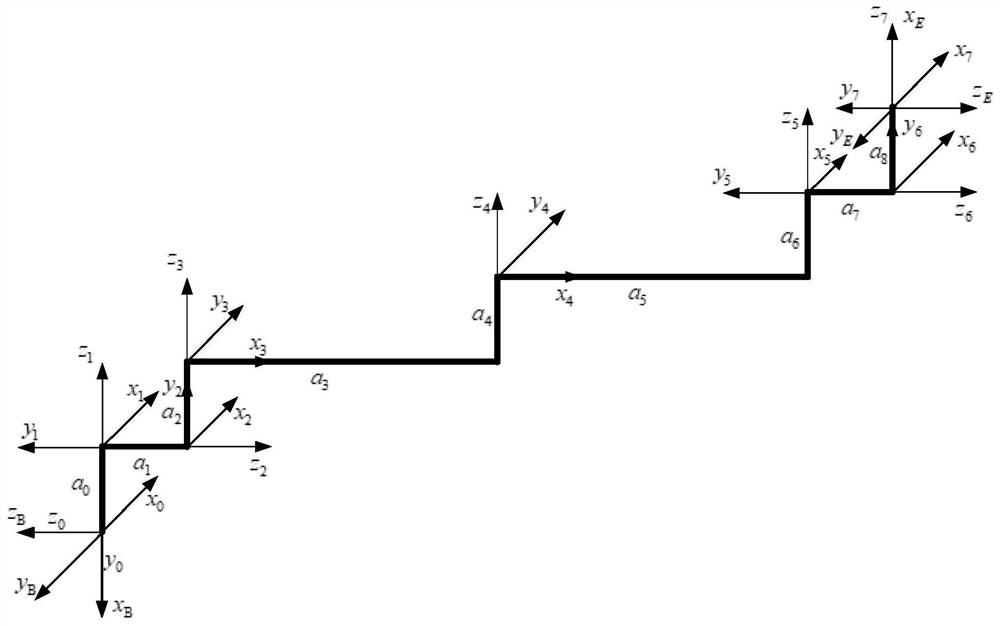

[0062] Step 11: For the 7DOF manipulator joint θ i (i=1, 2...7), fix a certain joint u, and regard it as a six-degree-of-freedom robotic arm. The positive kinematic relationship of the robotic arm can be expressed as:

[0063] f(x,u)=T (1)

[0064] Among them, x is the remaining joints except the joint u, T is the desired pose, which is a constant value when solving;

[0065] Step 1 and 2: Based on the joint angle parameterization method, the analytical solution of inverse kinematics is solved, and the corresponding position-level inverse kinematics is expressed as:

[0066] x=ikine(u, T, x 0 ) (2)

[0067] where x 0 is the initial configuration of the robot arm. In the motion space of the manipulator, regardless of the singular position of the manipulator, each corresponding to a fixed joint angle u and the corresponding end pose T, there is a set of corresponding ...

specific Embodiment approach 3

[0068] Specific implementation mode 3: Step 2 of this implementation mode considers the joint limit optimization criterion when establishing the optimal control problem. For each joint angle θ, the objective function that needs to be satisfied is:

[0069]

[0070] Among them, θ imax and θ imin are the upper and lower limits of the motion range of the i-th joint, respectively, formula (1) and formula (3) form the inverse kinematics solution problem of the seven-degree-of-freedom manipulator considering the joint limit optimization. The goal of optimization is to minimize H, and this optimization index keeps the joint motion of the manipulator away from the limit position. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com