High-precision mechanical arm operating platform

A technology for operating platforms and manipulators, applied in the field of manipulators, can solve the problems of inconvenient platform height, manipulator rotation, adjustment, etc., and achieve the effects of preventing movement, increasing the clamping range, and facilitating fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

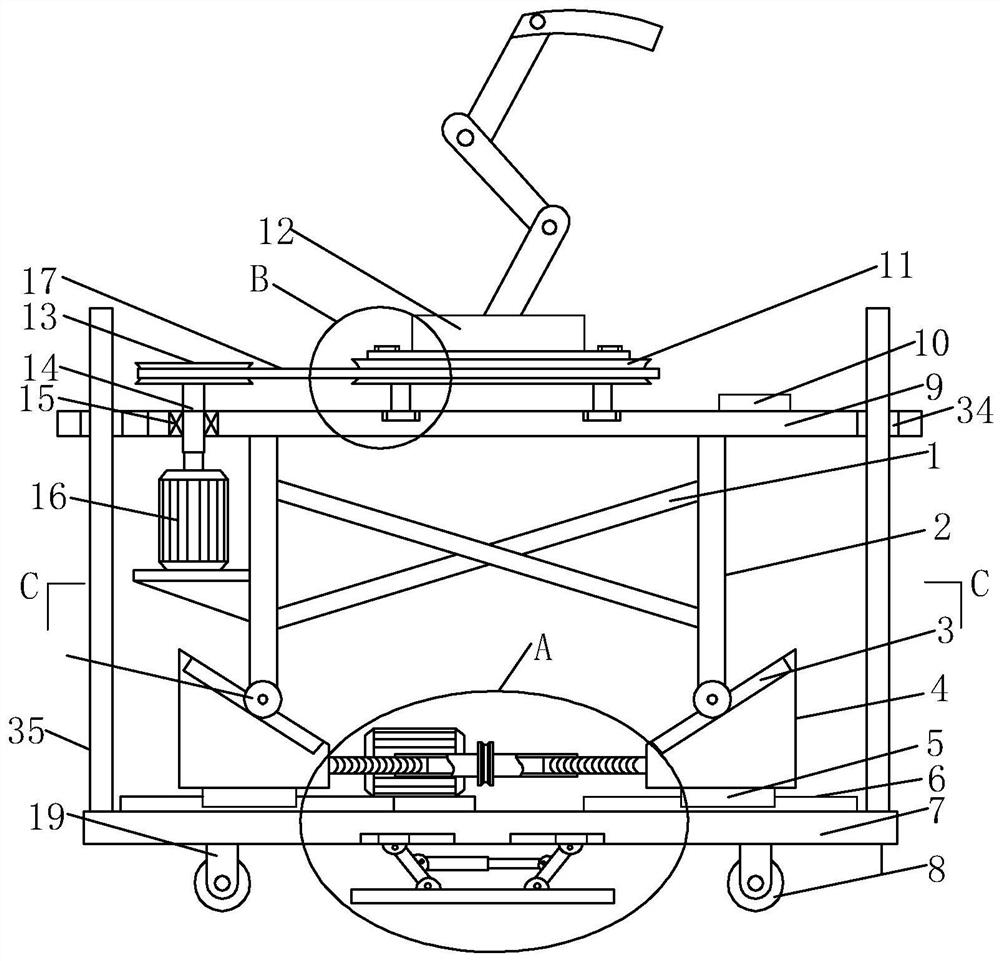

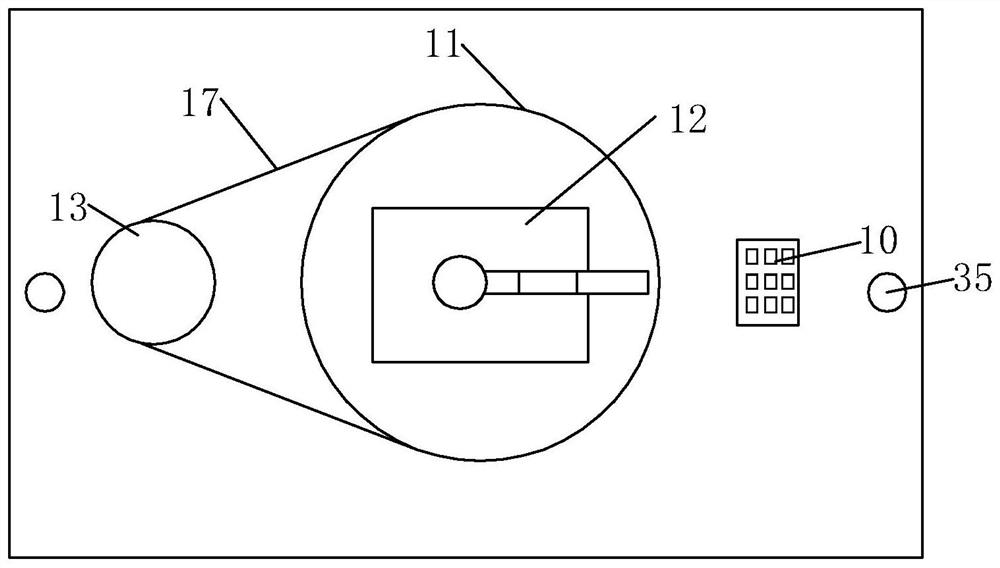

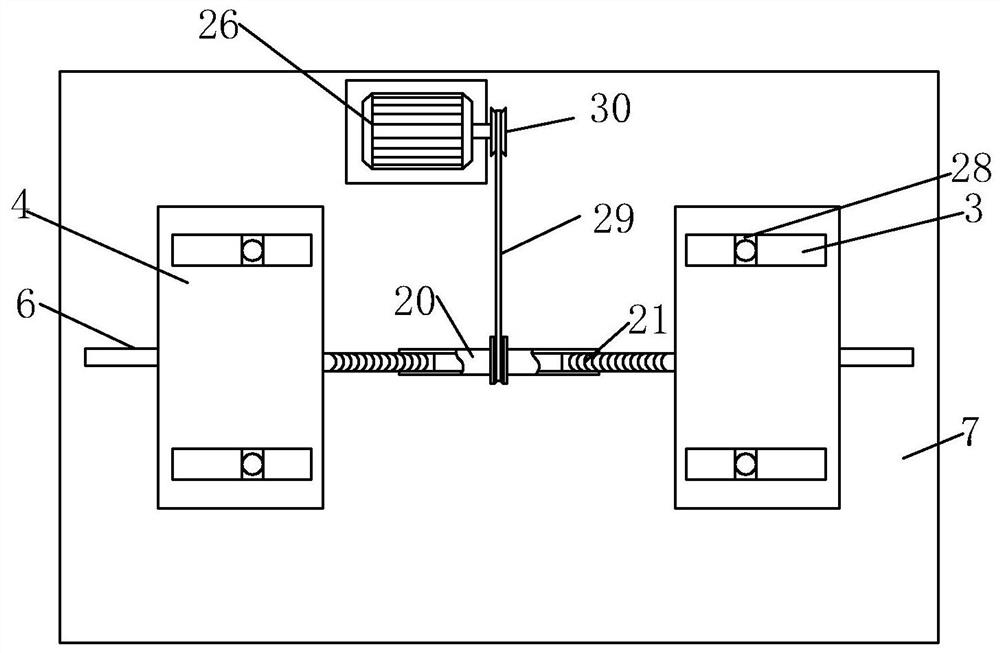

[0022]ReferenceFigure 1-5 , A high-precision mechanical arm operating platform, including a top plate 9, one end of the top plate 9 is fixedly installed with a controller 10, both ends of the top plate 9 are equipped with positioning mechanisms, the model of the controller 10 is MAM-100, the lower end of the top plate 9 is The support column 2 is fixedly connected, and the reinforcement frame 1 is fixedly connected between the support columns 2. The design of the reinforcement frame 1 strengthens the connection effect between the support columns 2 and is beneficial to the stability of the support column 2.

[0023]A bottom plate 7 is provided at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com