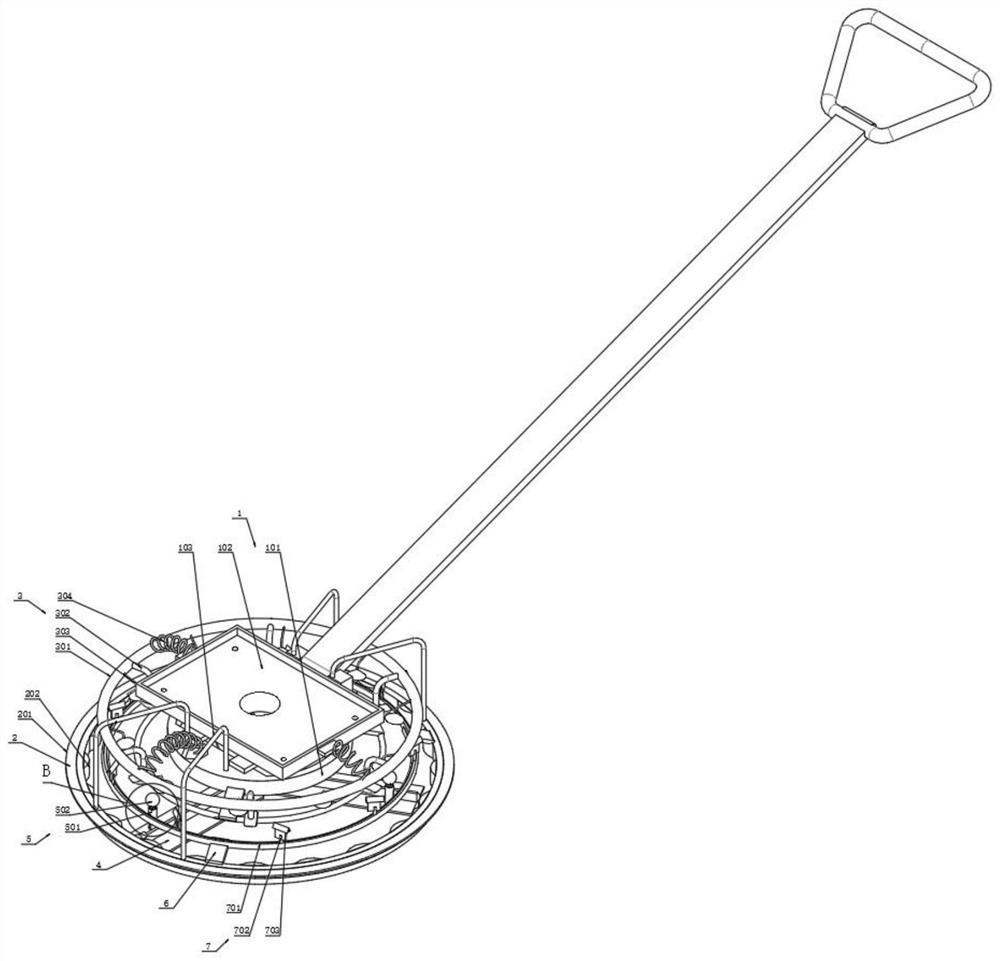

Concrete road leveling machine for building construction

A technology for concrete pavement and building construction, applied in construction, pavement cleaning, roads, etc., can solve the problems of harsh construction environment, lack of dust suppression mechanism, difficulty in solving dust problems, etc., and achieve the effect of ingenious structural design and a wide range of coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

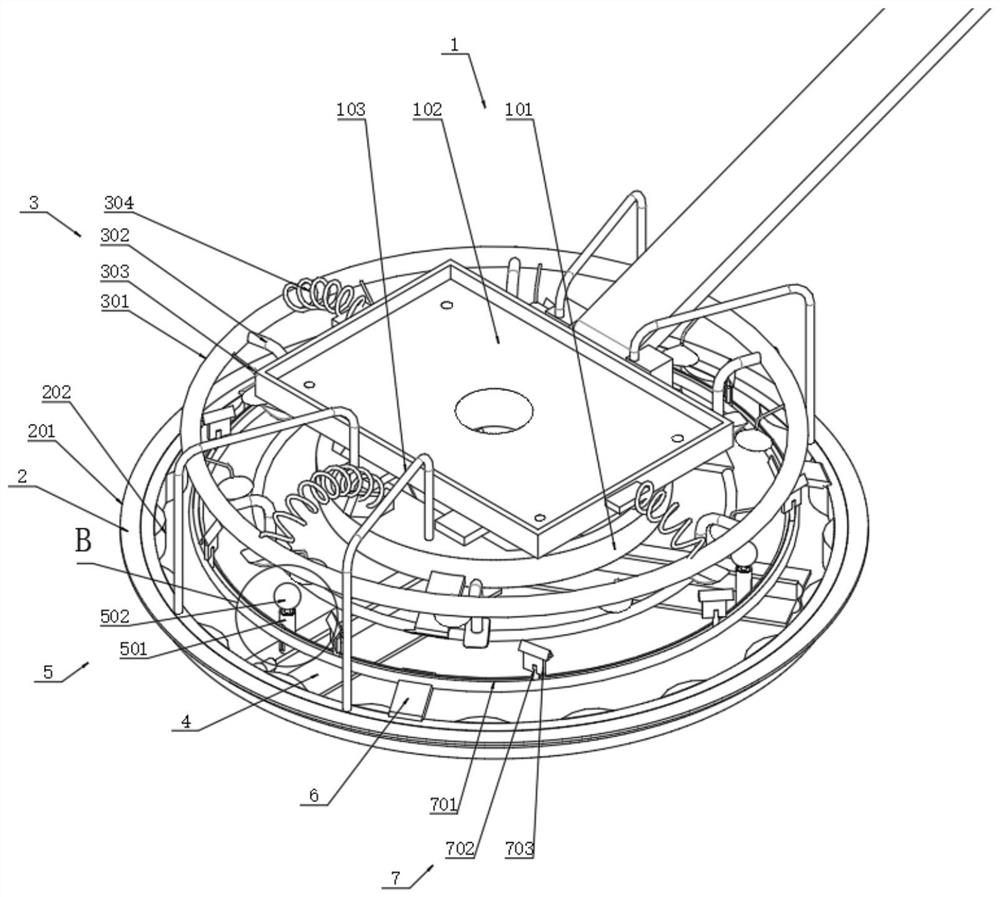

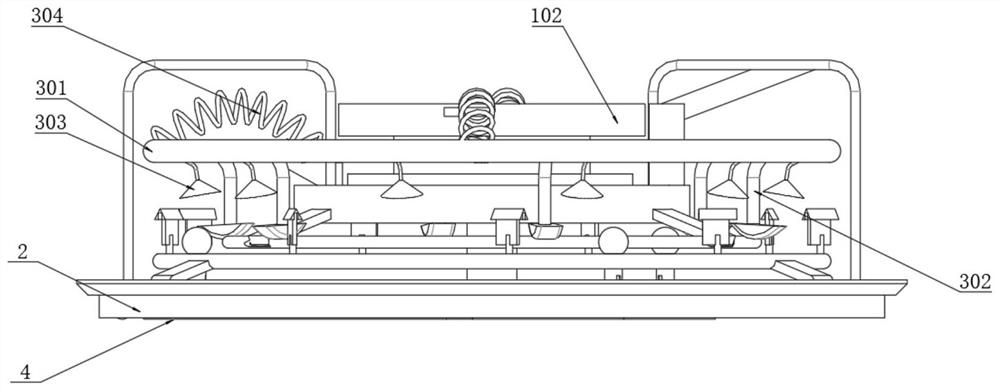

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

[0030] Concrete pavement leveling machine for building construction, including center seat mechanism 1, outer ring mechanism 2, nozzle mechanism 3, stop mechanism 5 and inner ring mechanism 7; center seat mechanism 1 includes seat 101 fixed on the top, fixed on seat 101 The top is used to install the motor fixing plate 102 of the driving motor, and the bottom surface of the seat 101 is equipped with a swivel seat 104 for driving and connecting with the motor. An outer ring mechanism 2 is installed on the outside of the four crutches 103, and the outer ring mechanism 2 is a functional ring structure based on the outer ring of the center seat mechanism 1, such as Figure 4 , Figure 6 As shown, the outer ring mechanism 2 includes an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com