Exhaust gas system for exhaust gas after-treatment

An exhaust system and exhaust gas technology, applied in exhaust treatment, exhaust equipment, air quality improvement, etc., can solve the problems of increasing fuel consumption, exhaust system blockage, increasing harmful substance emissions, etc., and achieve the effect of avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The same reference numerals designate the same or corresponding elements.

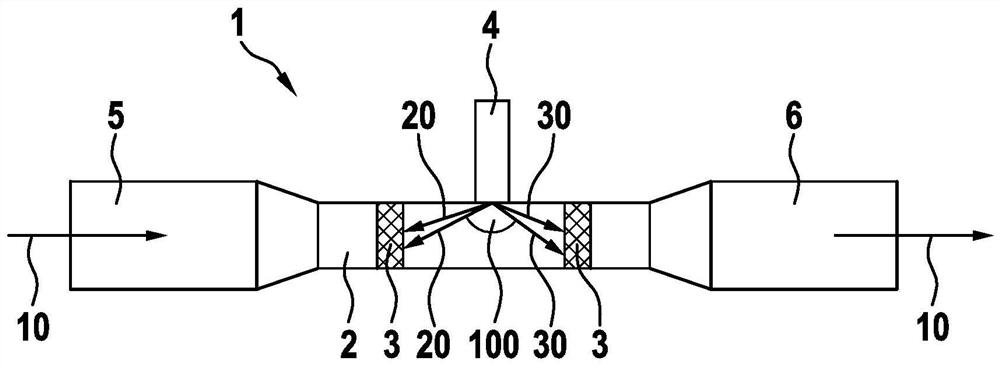

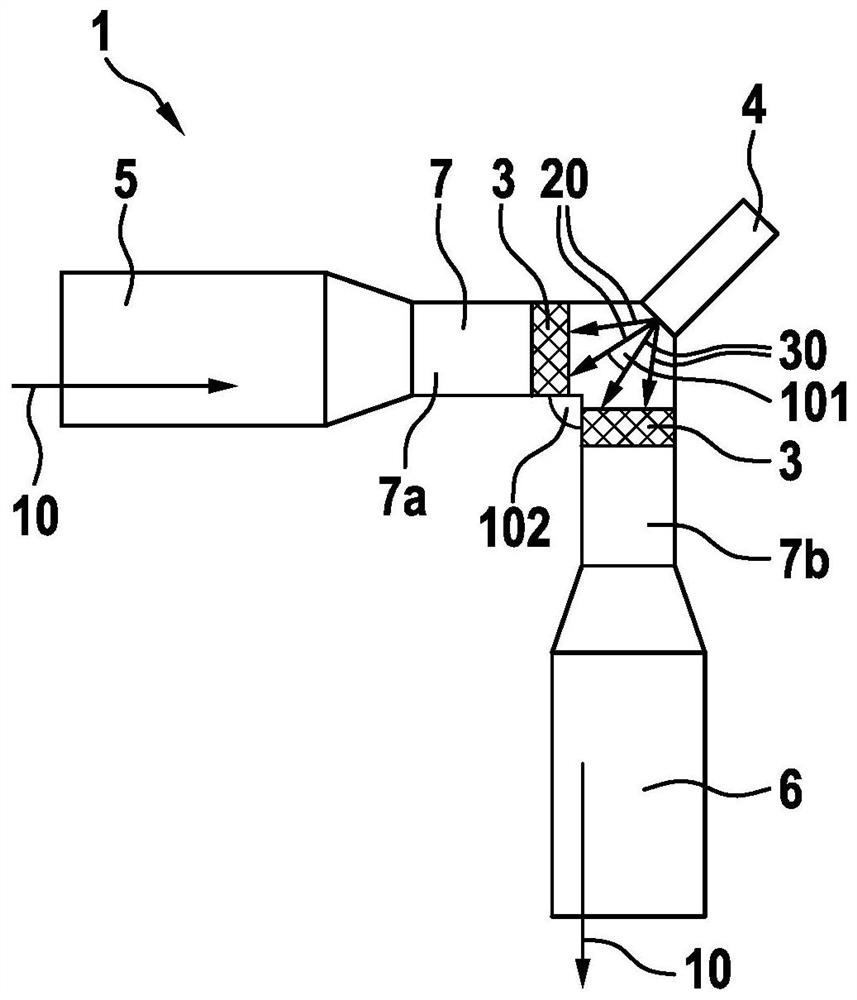

[0023] figure 1 A first exemplary embodiment of an exhaust gas system 1 is shown, which has a straight section 2 through which the exhaust gas flows in the gas flow direction indicated by the arrow 10 . The two mixing elements 3 are arranged at a distance relative to each other in the straight section 2 of the exhaust gas system 1 .

[0024] A metering module 4 is arranged between the two mixing elements 3 , which is provided for injecting or feeding in a fluid. The fluid may be a fluid reducing agent, especially a urea solution, which should be mixed with the exhaust gas. For this purpose, the metering module 4 injects the fluid into the exhaust gas in the form of fine droplets in the direction of the mixing element 3 . The metering module 4 is arranged such that a mixing element 3 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com