A design method for shift schedule of super multi-gear automatic transmission

A technology of automatic transmission and shifting regularity, applied in mechanical equipment, transmission control, components with teeth, etc., can solve the problem that the shifting regularity of ordinary transmission cannot be applied to super multi-speed automatic transmission and super multi-speed automatic transmission. Problems such as complex shifting rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

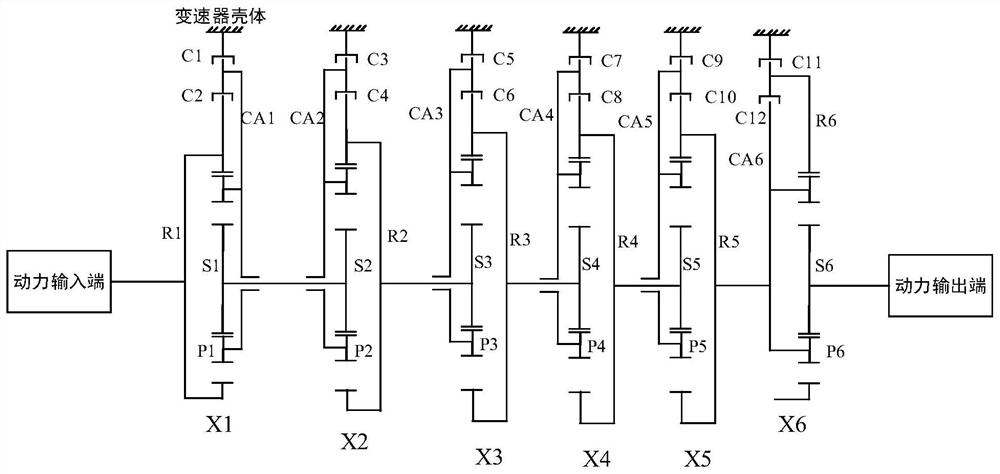

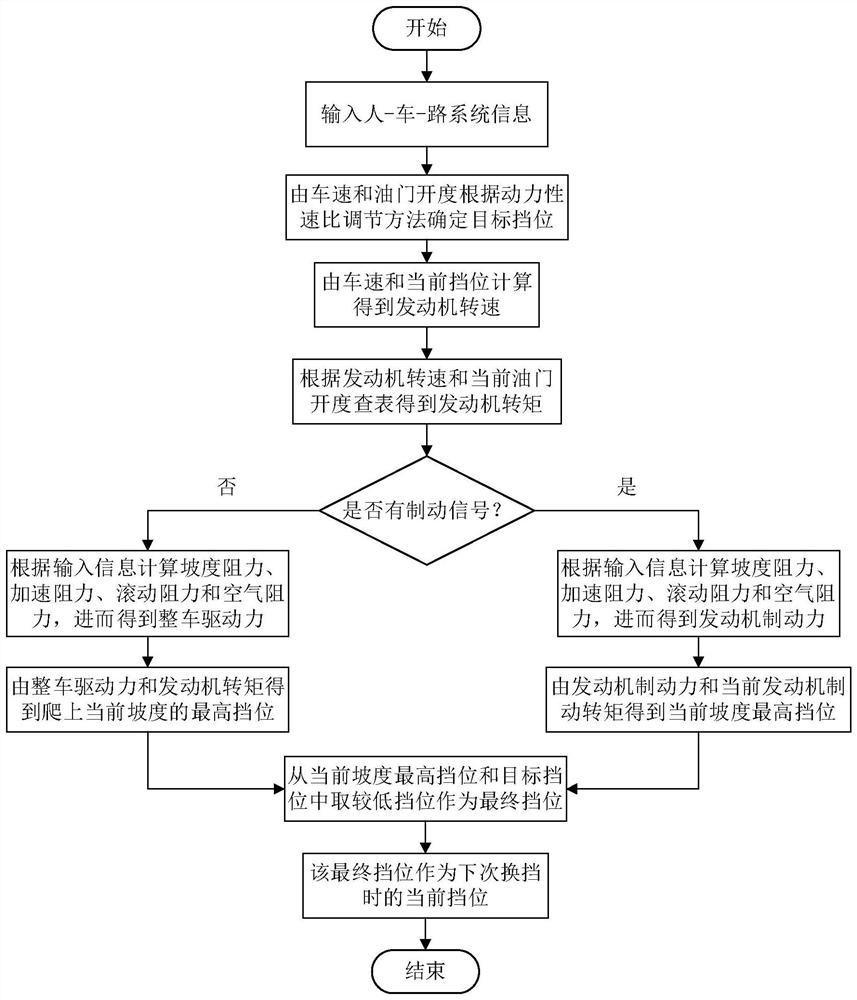

[0043] refer to figure 1, in order to solve the problems in the prior art, the present invention provides a method for designing a shift schedule of a super multi-gear automatic transmission, wherein the super multi-gear automatic transmission includes a planetary row X1, a planetary row X2, a planetary row X3, a planetary row X4, planetary row X5 and planetary row X6, planetary row X1, planetary row X2, planetary row X3, planetary row X4 and planetary row X5 are forward gear planetary row, planetary row X6 is reverse gear planetary row, planetary row X1 includes the sun Wheel S1, planetary gear P1, ring gear R1, planetary carrier CA1, brake C1 and clutch C2, planetary row X2 includes sun gear S2, planetary gear P2, ring gear R2, plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com