Straight flow type ball sealing check valve and use method thereof

A technology of check valves and rubber balls, applied in valve details, valve devices, control valves, etc., can solve the problems of oblique slideway blockage, blockage of liquid flow, large resistance, etc., and achieve easy maintenance and replacement, check effect Good, fast closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

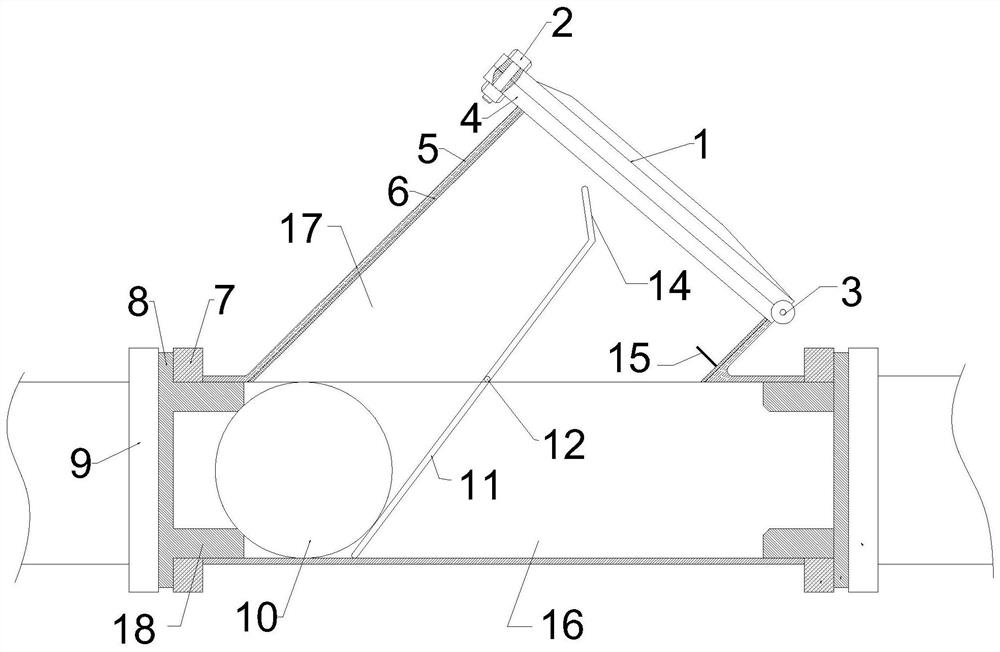

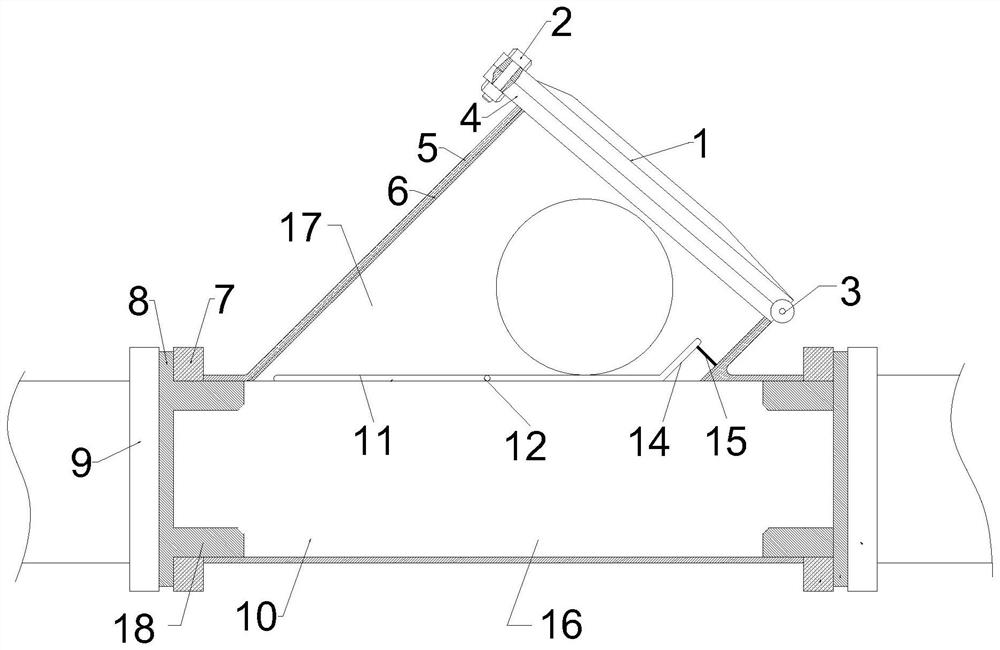

[0032] Such as Figure 1-3 ,and Image 6 As shown, a direct current type ball seal check valve proposed in this embodiment includes a valve body 5 and a rubber ball 10 arranged in the valve body 5. The valve body 5 has a three-way structure as a whole. The medium channel 16 for the liquid to enter and exit, the left end is the inlet, and the right end is the outlet. The medium channel 16 is arranged in a straight shape; It is inclined, and the valve cover 1 is detachably connected to the port of the installation passage 17. The specific structure is: the third flange piece 4 is fixedly welded at the port of the installation passage 17, and the valve cover 1 is connected to the third flange through the rotating shaft 3. The blue piece 4 is hinged, the valve cover 1 can rotate around the rotation axis 3, the valve cover 1 is fixedly connected with the third flange piece 4 through the bolt 2, and an O Type ring to improve the sealing effect.

[0033] Both ends of the valve bod...

Embodiment 2

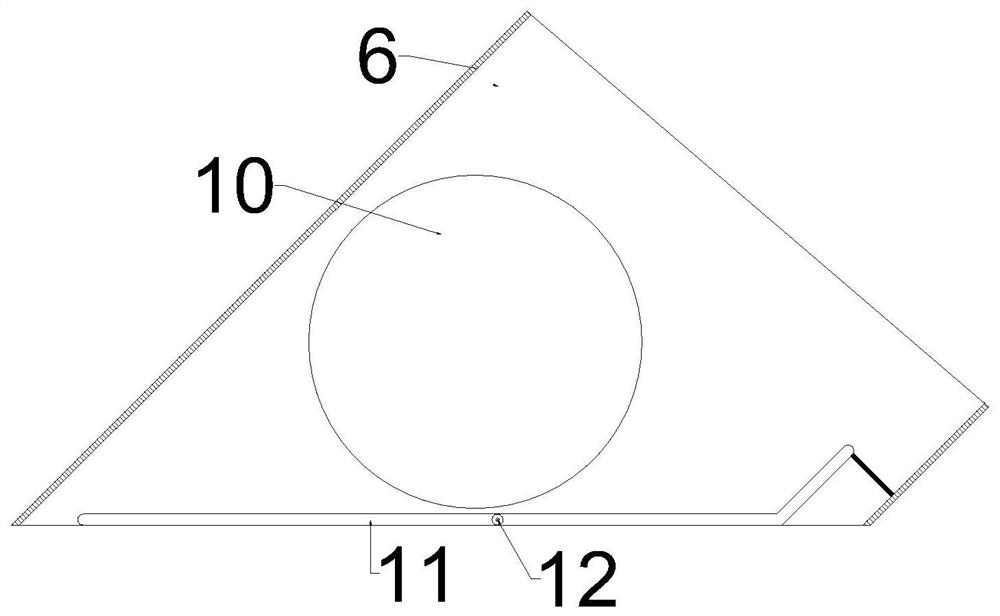

[0045] Such as Figure 4-5 As shown, on the basis of Embodiment 1, a baffle is provided on the rotating plate 11, and the baffle can be arranged at an inclination to block the rubber ball 10. When the rubber ball 10 contacts the baffle, the rubber ball The center of the sphere of 10 and the center line of bearing pin 12 are coplanarly arranged. In addition, since the surface of the rubber ball 10 is an elastic rubber layer, the water flow impacts the rubber ball 10 to make it contact with the baffle and squeeze it, deforming it and generating a certain elastic force.

[0046] The purpose of such setting is that when the liquid is pumped, the impact force of the liquid drives the rubber ball 10 to move and support on the surface of the baffle, which can drive the baffle to rotate rapidly, and then drive the rotating plate 11 to reach a horizontal state quickly, and the rotating plate 11 The right end is pressed against the limit post 15. At this time, the ball center of the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com