Heat dissipation and shock absorption protection device for gas equipment

A protection device and equipment heat dissipation technology, applied in valve devices, mechanical equipment, household refrigeration devices, etc., can solve problems such as equipment cannot automatically open emergency shut-off valve, gas equipment leakage, etc., to improve the safety of use and avoid excessive temperature. High, the effect of expanding the heat dissipation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

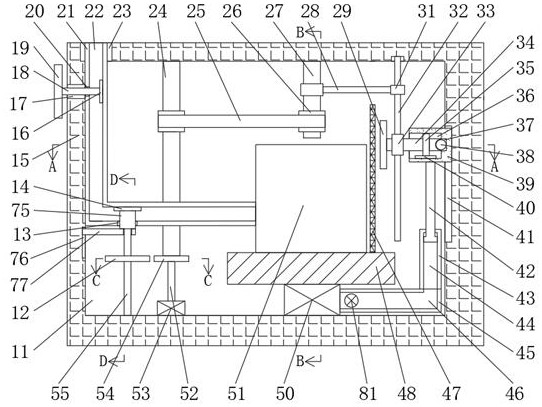

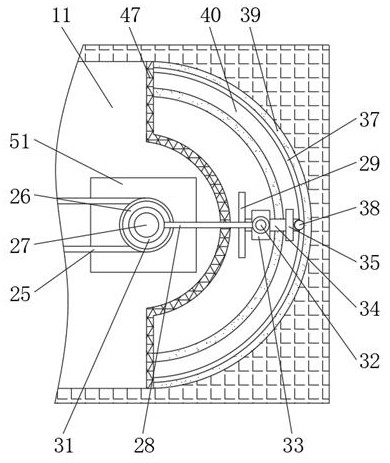

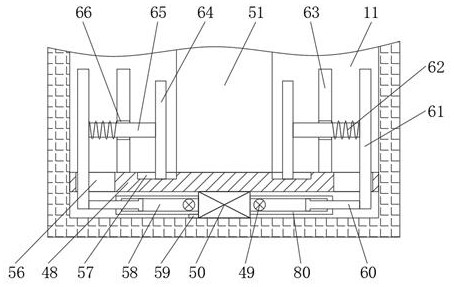

[0016] Combine below Figure 1-Figure 5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017]A heat dissipation and shock absorption protection device for gas equipment according to the present invention includes a base 15, an inner cavity 11 is arranged inside the base 15, and an outlet hole 23 with an upward opening is communicated with the upper wall of the inner cavity 11, and the inner cavity 11, the left wall communicates with a through hole 17 opening to the left, a support plate 48 is connected between the front and rear walls of the inner cavity 11, and a protective net 47 is fixedly connected to the upper right side of the support plate 48, and the front and rear ends of the protective net 47 They are fixedly connected to the front and rear walls of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com