Loading test device and system for testing chloride ion permeation law in concrete test piece

A technology for loading test devices and concrete specimens, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

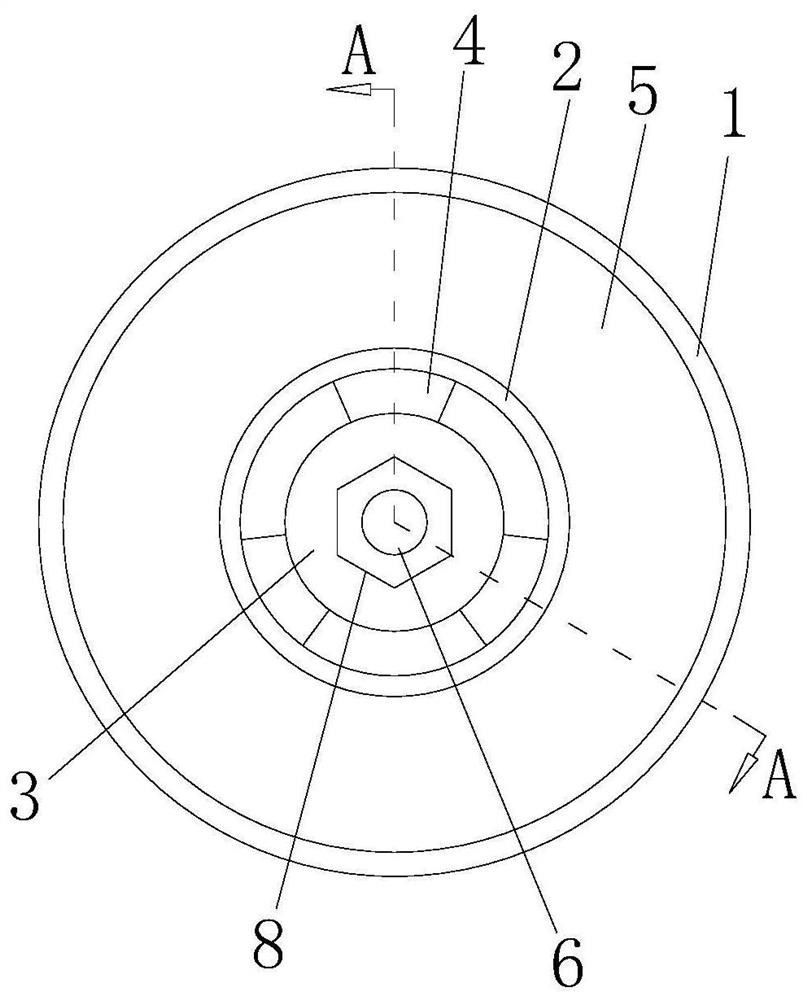

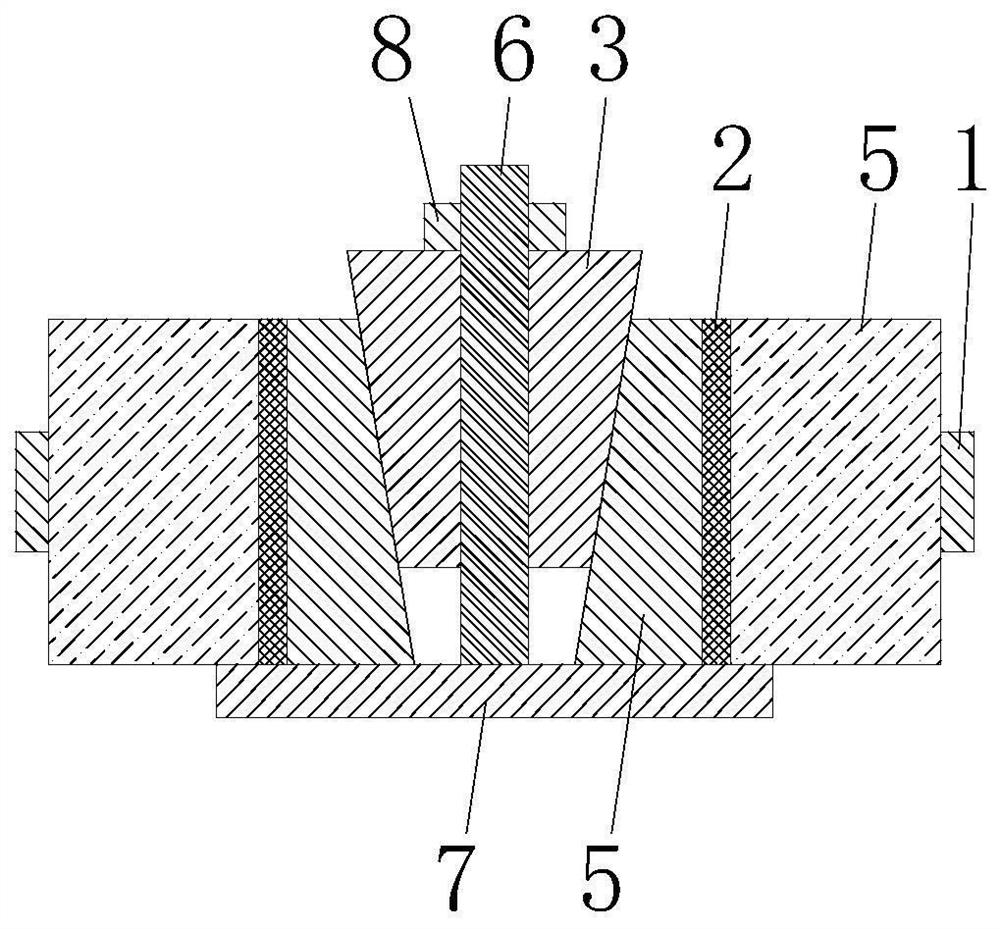

[0037] A loading test device for testing the law of chloride ion penetration in concrete specimens, used to apply compressive stress to concrete specimens 5, such as figure 1 and figure 2 As shown, it includes an outer retaining ring 1, an inner pressure ring 2, a tapered pressure sleeve 3, a wedge-shaped pressing block 4 and a pressing device.

[0038] Wherein, the outer retaining ring 1 is a rigid component, such as aluminum or steel, which wraps around the concrete specimen 5 so that the concrete specimen 5 is confined within the area surrounded by the outer retaining ring 1 .

[0039] The inner pressure ring 3 is placed inside the outer retaining ring 1, and the two are usually coaxially arranged and located in the same plane, while the above-mentioned concrete specimen 5 is placed between the inner pressure ring 3 and the outer retaining ring 1, and passed through the following The components are fastened therein. In this embodiment, the configured inner pressure ring ...

Embodiment 2

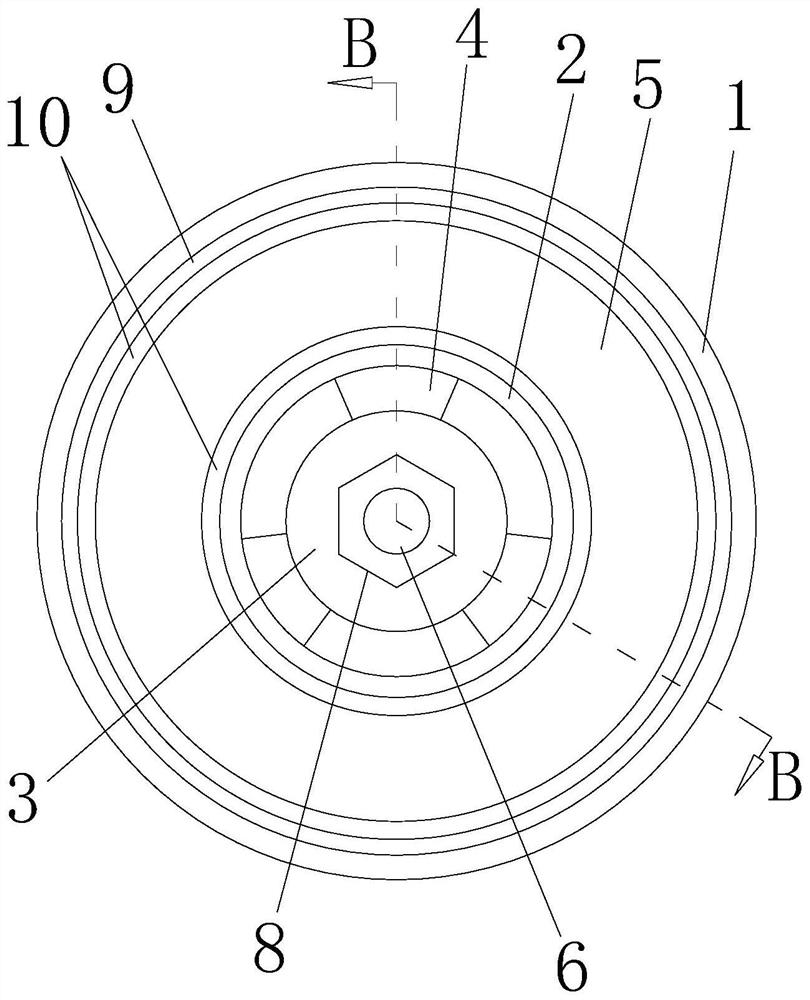

[0048] The difference from Embodiment 1 is that in this embodiment, the taper angle of the conical gland 3 is 10°, which is relatively large, which makes the conical gland 3 only need a small stroke to work. Applying a predetermined pressure to the concrete test piece 5 further reduces operational requirements.

Embodiment 3

[0050] The difference from Embodiment 1 is that in this embodiment, the conical angle of the conical gland 3 is 7°, which is between the conical angles of the conical gland 3 in Embodiment 1 and Embodiment 2. Therefore, when operating under the cone angle, the lock nut 8 can not only have an observable movement stroke, but also provide the predetermined pressure required by the concrete test piece 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com