Electronic manufacturing industry collaborative innovation platform and using method thereof

A manufacturing and platform technology, applied in the field of electronic manufacturing collaborative innovation platform, can solve the problem of not being able to participate in it and having to wait for the final result, and achieve the effect of shortening product design time, shortening product processing time, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

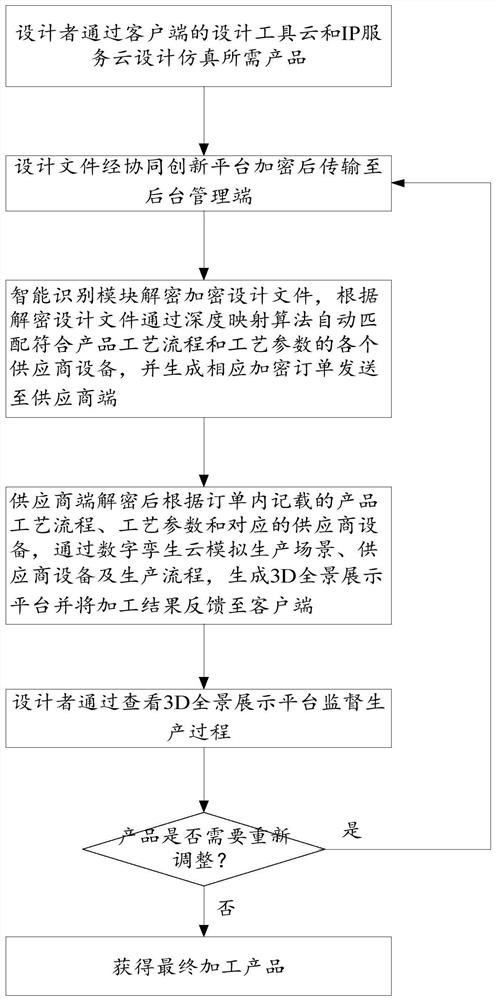

[0036] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

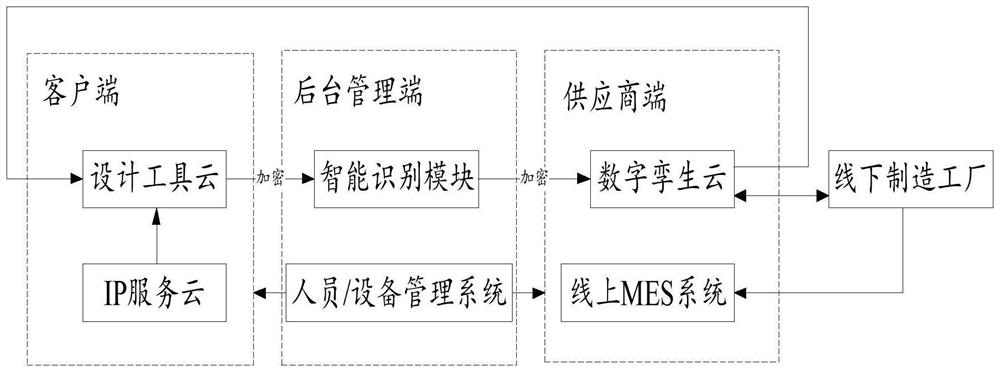

[0037] This application discloses a collaborative innovation platform for the electronics manufacturing industry, its principle block diagram is as follows figure 1 As shown, including client, background management and supplier.

[0038] The client includes design tool cloud and IP service cloud. The design tool cloud is used to realize online circuit design, structural modeling, process simulation and layout drawing. The design tool cloud includes simulation software. Optionally, the simulation software is Intellisense software for collaborative innovation In the later stage of the platform, we will gradually introduce diversified cooperation with domestic and foreign well-known design simulation software such as Ansys, Comsol, Covontorware, Sugar, etc. The IP service cloud integrates a variety of IP packages for designers to use directly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com