Optical modulation element

一种光调制元件、光调制层的技术,应用在光学元件、光学元件、光学部件等方向,能够解决产品品质劣化、表面弯曲等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

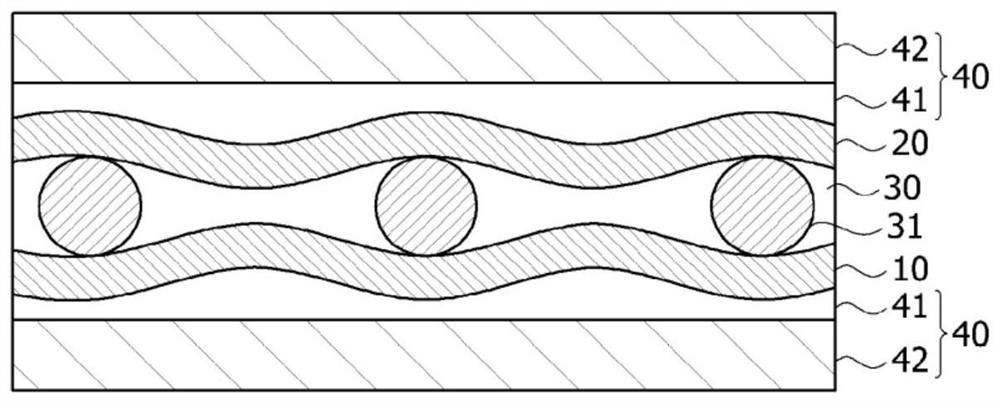

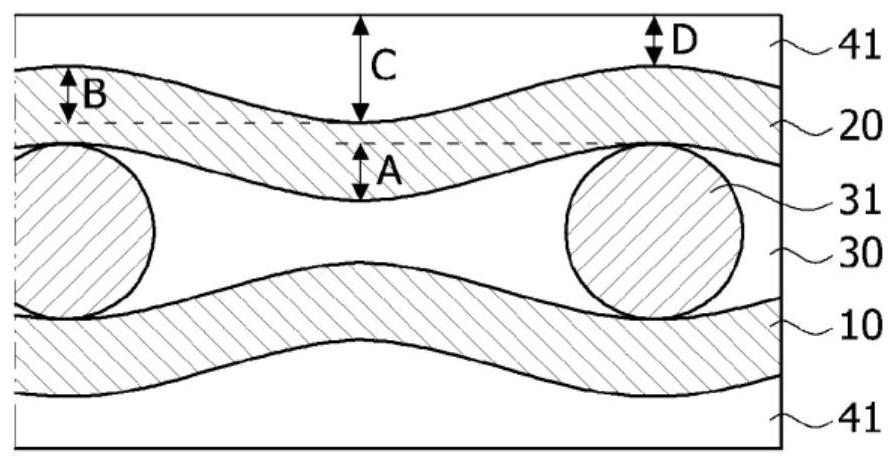

[0068] As the light modulation element of Example 1, a light modulation element having the shape of an eyewear lens was produced. Specifically, as a film having an electrode layer formed on each of the first base film and the second base film, a PC-ITO film (Teijin) having a total thickness of 100 μm was prepared in which the ITO layer was deposited on the PC film superior. A composition comprising a liquid crystal compound (MDA-16-1235, Merck) and a spherical spacer (KBN-512, Sekisui Co.) having a particle diameter of 12 μm was applied on the electrode layer of the first substrate film to form a light modulation layer . At this point, the composition was applied on the PC-ITO film in the inner region of the outer sealant applied in the shape of the edge of the eyewear lens. After the second base film is laminated so that the electrode layer of the second base film is in contact with the light modulation layer, due to the difference in force between the first base film and t...

Embodiment 2

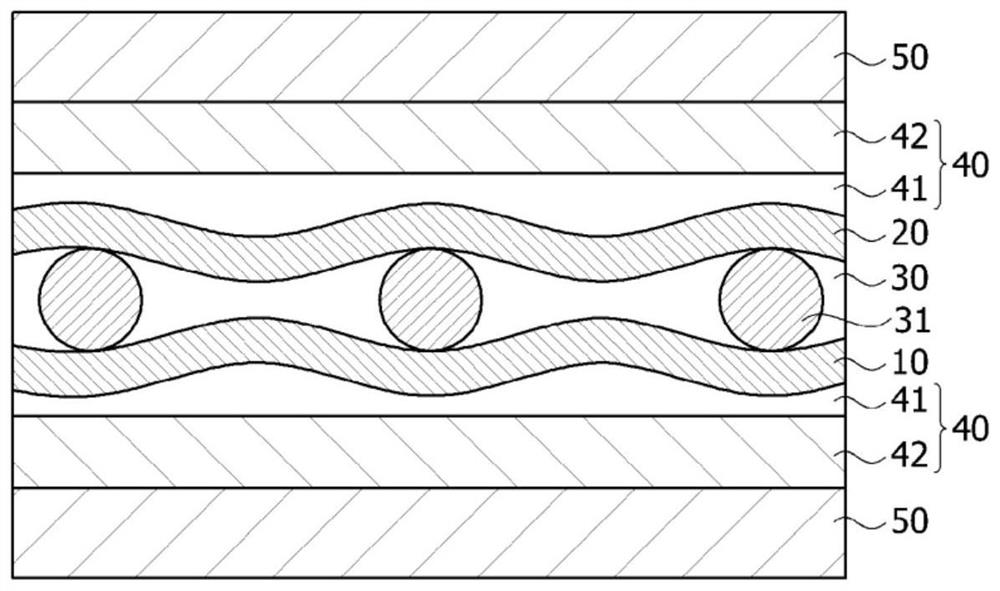

[0070] A light modulation element was manufactured in the same manner as in Example 1 except that a TAC film (SHC40T190M, DAICEL) having a thickness of 190 μm in which a hard coat layer was formed on one side instead of the anti-fog layer was used.

Embodiment 3

[0072] A light modulation element was produced in the same manner as in Example 1, except that a PC film (OM81-5, Polyopt) having a thickness of 500 μm in which a hard coat layer was formed on one side was used instead of a hard coat layer formed on one side. TAC film with a thickness of 190 μm coated with an anti-fog layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com