Stirrer of machine for making liquid or semi-liquid products and machine comprising stirrer

A semi-liquid, agitator technology, applied in the direction of mixers with rotating agitation devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of hardship, removal of blades is not easy, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

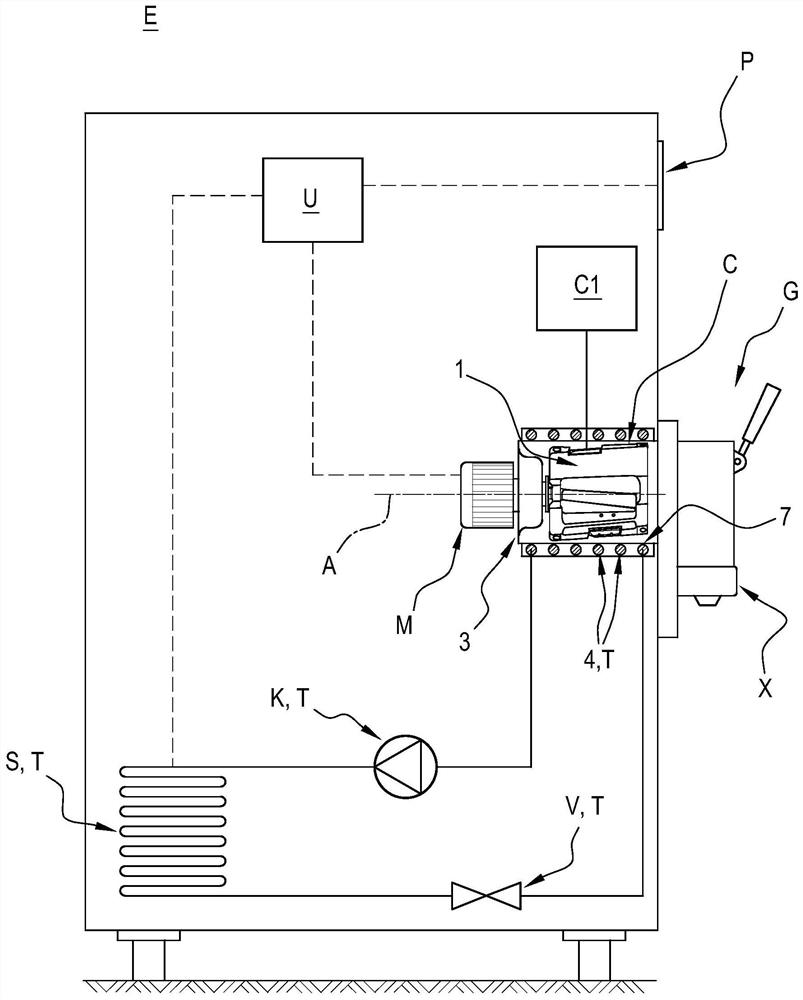

[0027] refer to figure 1 , reference numeral 1 designates as a whole a mixer of a machine G for making liquid or semi-liquid products, in particular a machine G for making and dispensing ice cream (both mixer 1 and machine G are objects of the invention) .

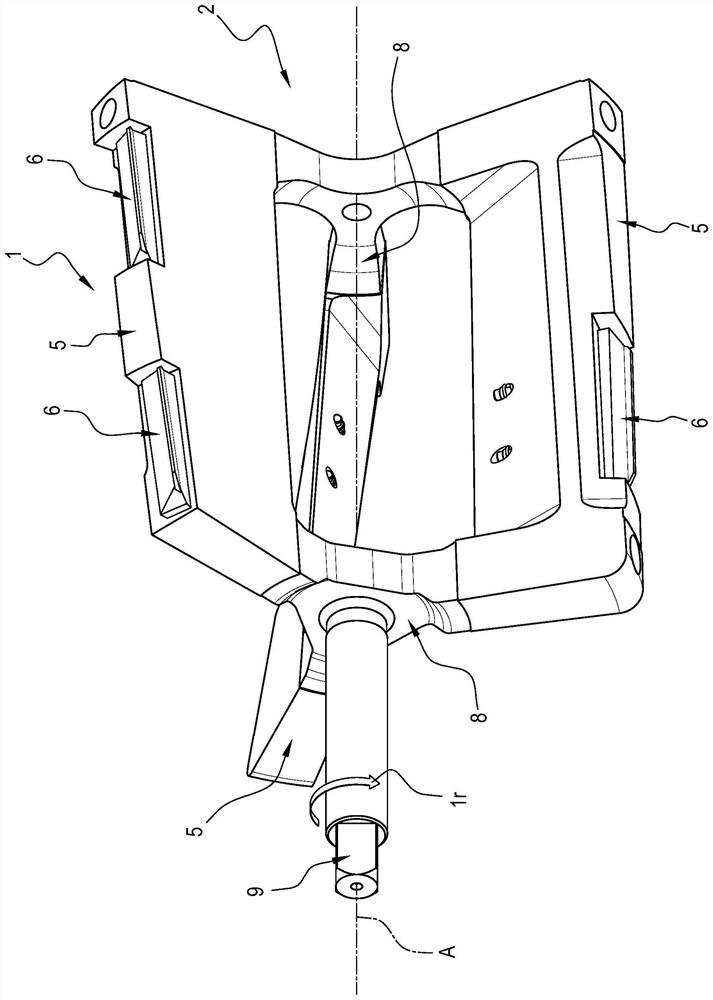

[0028] Stirrer 1 comprises rotating body 2 ( figure 2 ), the rotating body 2 is coaxially accommodated in the batch freezing cylinder 3 of the machine G to rotate about its central axis A.

[0029] The function of the batch freezing cylinder 3 , cooled in a known manner by means of coils 4 , is to receive the product to be cooled, to process it to make a consumable product, and to store the product as it is by means of the continuous rotation of the agitator 1 inside it. The direction of rotation of the stirrer 1 is figure 2 Marked as 1r in.

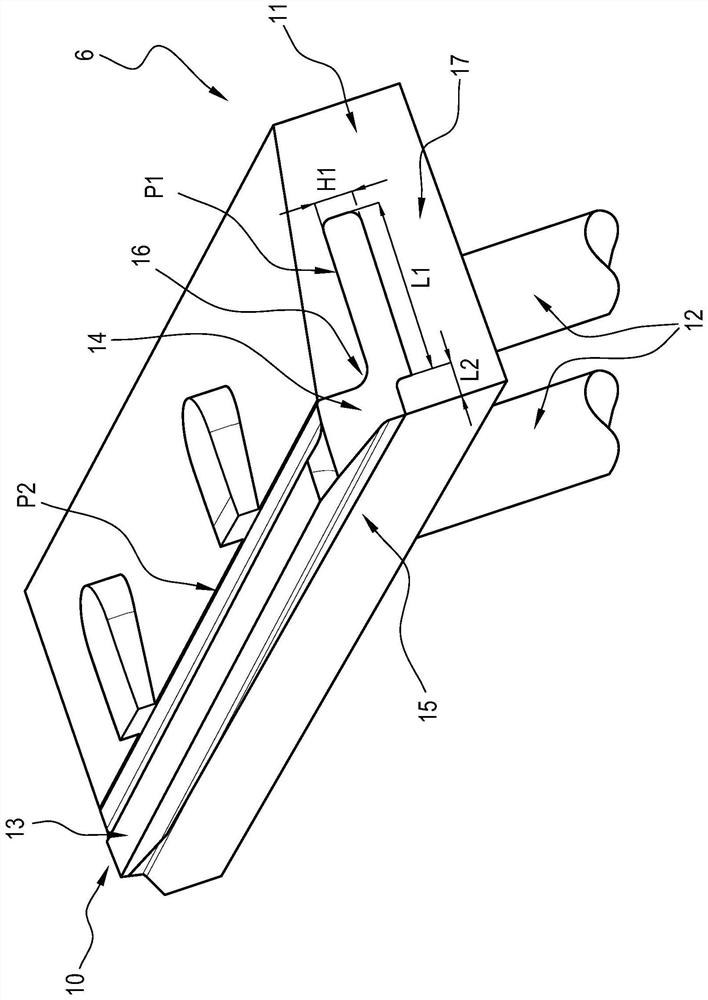

[0030] The agitator 1 is provided with a plurality of blades 5 arranged in radially peripheral positions about the above-mentioned axis A and each blade 5 is provided with at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com