Civil air defense door frame hydraulic correcting device

A civil air defense door frame and hydraulic technology, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of poor welding quality, low positioning accuracy, and large workload of manual welding, saving hoisting time and ensuring correction accuracy. , the effect of preventing bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

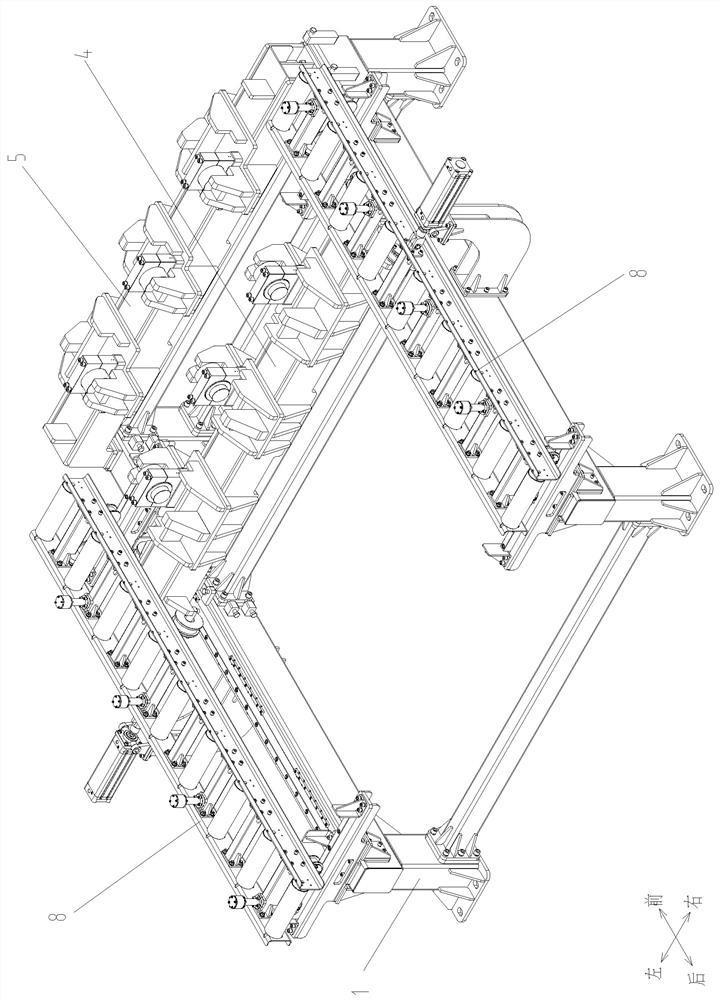

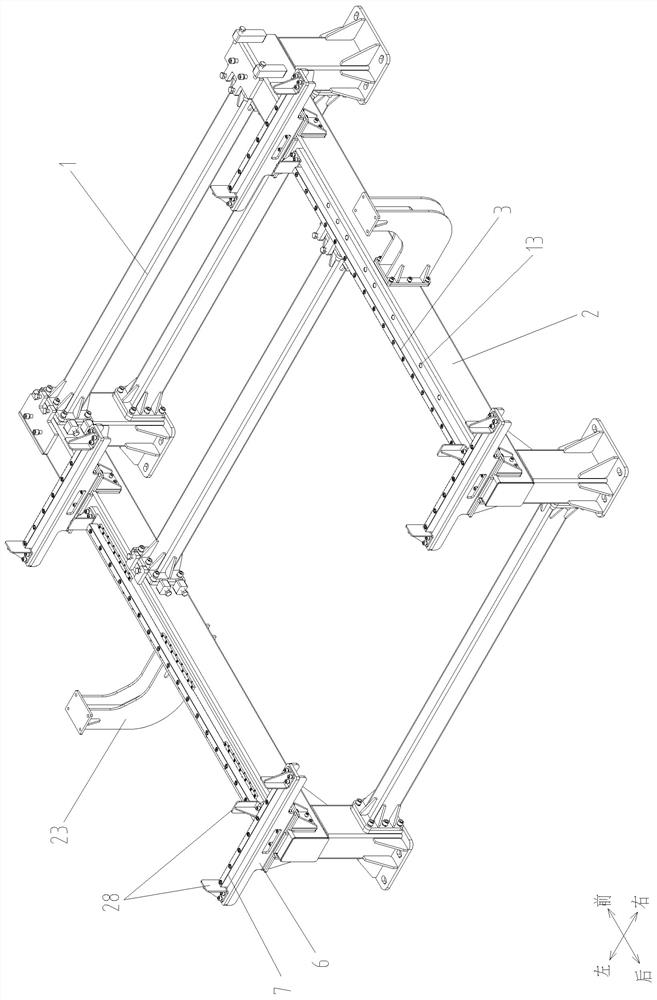

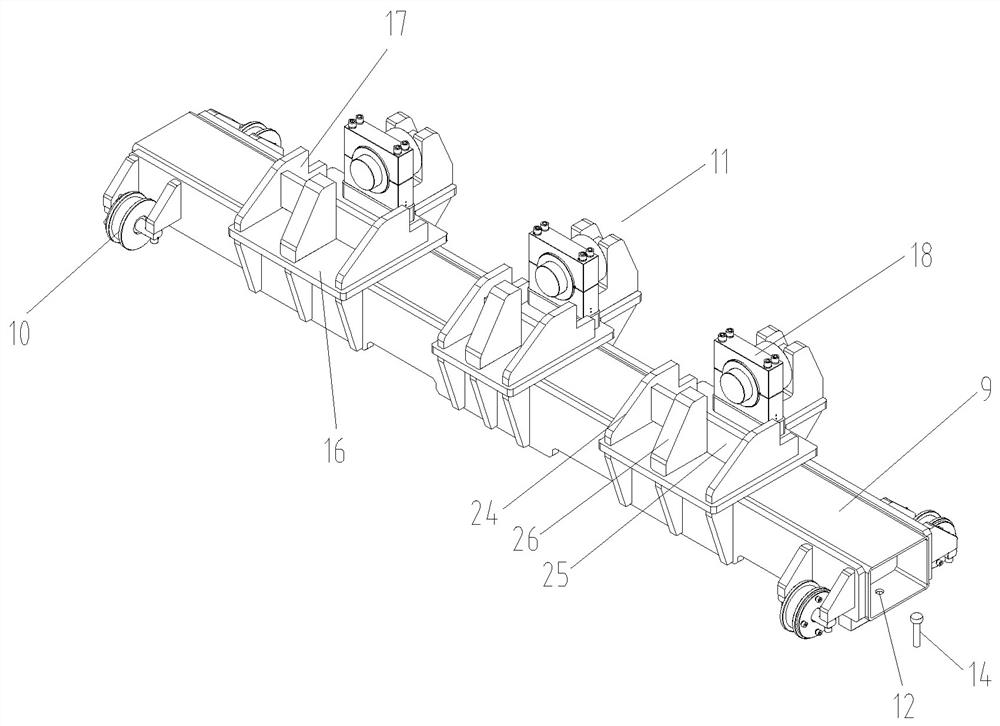

[0022] Such as Figure 1-5 As shown, the personal anti-door frame hydraulic correction device is provided with an underframe 1, a longitudinal beam 2 is respectively provided on the left and right sides of the underframe 1, and a longitudinal guide rail 3 is provided on each fixed frame at the middle and rear of the two longitudinal beams 2 top surfaces. The horizontal span on the two longitudinal guide rails 3 has a movable beam correction assembly 4 that can slide back and forth along the longitudinal guide rails 3, and the front transverse span on the top surface of the two longitudinal beams 2 has a fixed beam correction assembly 5; the two longitudinal beams 2 The top surface is respectively erected with a section of horizontal guide rail 7 which is set up through the guide rail seat 6 at the front and rear ends of the longitudinal guide rail 3, and there is a lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com