Device and method for producing tube body with optimized cooling device

A technology for cooling devices and equipment, applied in applications, tubular items, household appliances, etc., can solve problems such as high cost, affect effective heat output, high complexity, etc., achieve cooling power optimization, improve heat extraction, and improve heat transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

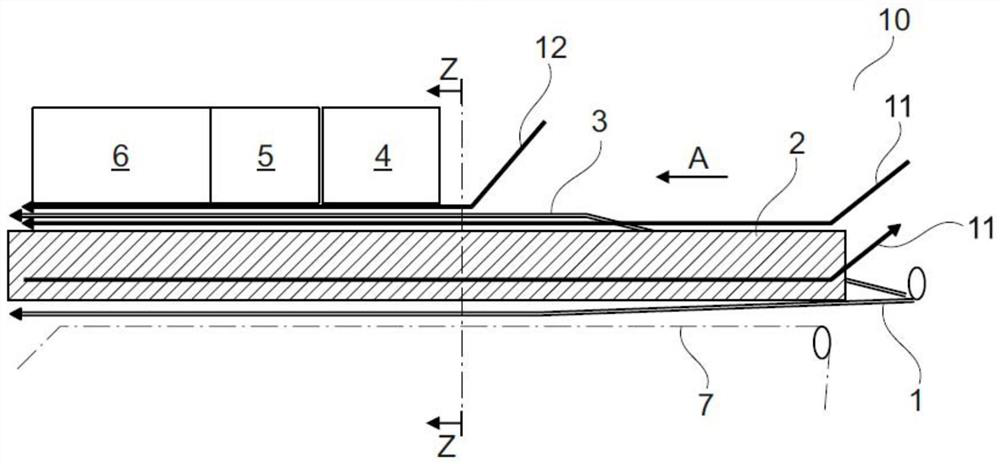

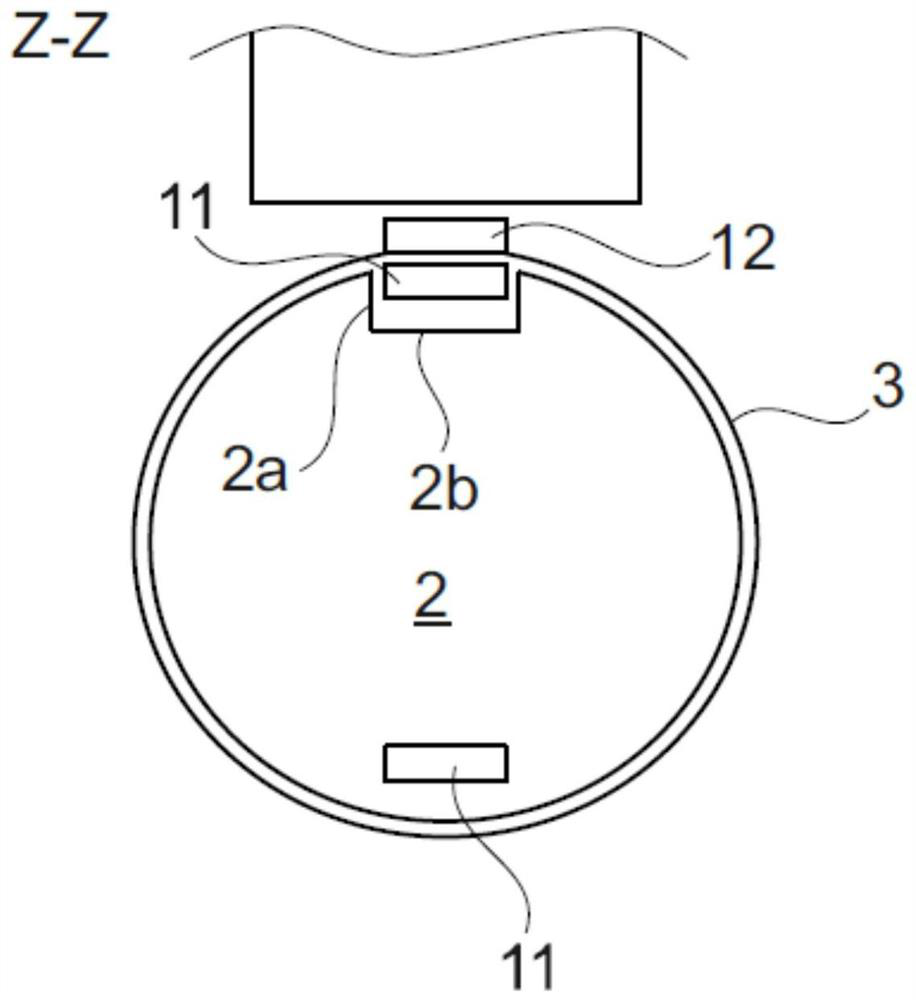

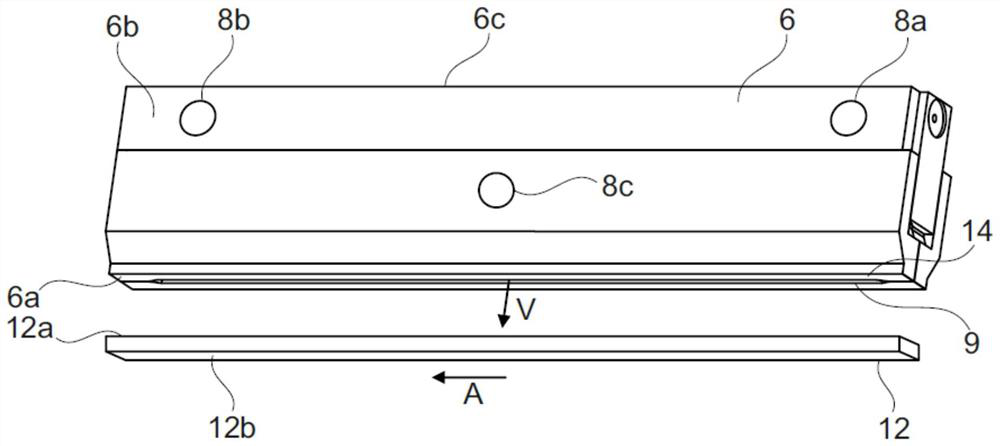

[0044] Figure 1a A very schematic longitudinal section view of an apparatus 10 for producing pipe bodies is shown. The device 10 comprises an elongated mandrel 2 around which a material web 1, here configured as a plastic laminate, can be deformed into a substantially circular tubular piece 3 by means of a forming device 7, here configured as a forming belt, , the tubular piece can then be welded to itself using a welding tool 4, in particular an induction welding device. Using the welding device 4 , the edge regions of the incoming material webs that abut against each other or overlap each other in the welding zone are welded to one another and produce a weld seam that extends or runs along the mandrel 2 . In the exemplary embodiment shown, a pressing device 5 is arranged downstream of the welding device 4 in the transport direction A of the material web 1 , which press device exerts a settable contact pressure on the newly welded tubular part 3 . A cooling device 6 for coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap