Power equipment defect management system based on AHP and remote support

A technology for electrical equipment and defect management, applied in information technology support systems, electrical digital data processing, data processing applications, etc., can solve problems such as deficiencies, restrict the development of live detection technology, and missed detection, and improve detection speed and accuracy. , good social and economic benefits and application promotion prospects, the effect of reducing power outage losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the enumerated embodiments are only used to explain the present invention, and are not intended to limit the scope of the present invention.

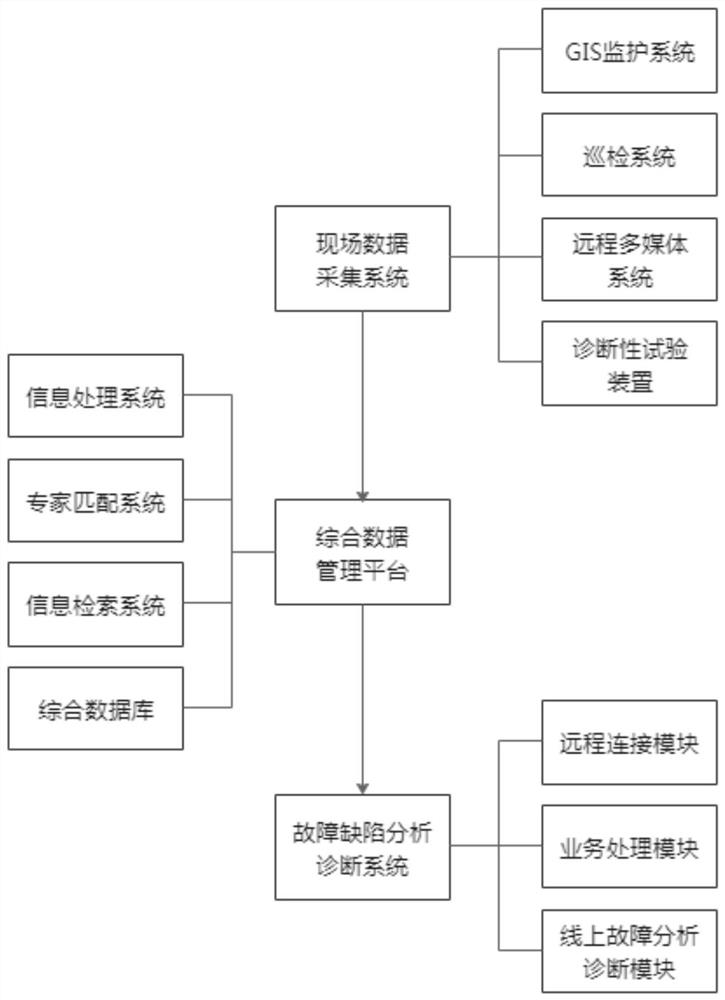

[0021] refer to figure 1 , The present invention provides an electric equipment defect management system based on AHP and remote support, the system includes an on-site data acquisition system, a comprehensive data management platform and a fault defect analysis and diagnosis system. The on-site data acquisition system is used to collect on-site operation information of substation equipment and send it to the comprehensive data management platform. The comprehensive data management platform is used to realize the storage and management of comprehensive data, analyze and evaluate the level of equipment index data, and confirm the reliability of data. The comprehensive data includes basic parameters of sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com