Torsion-resistant robot arm cable

A robot arm, torsion-resistant technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems such as accidents, restricting work time, and inability to meet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

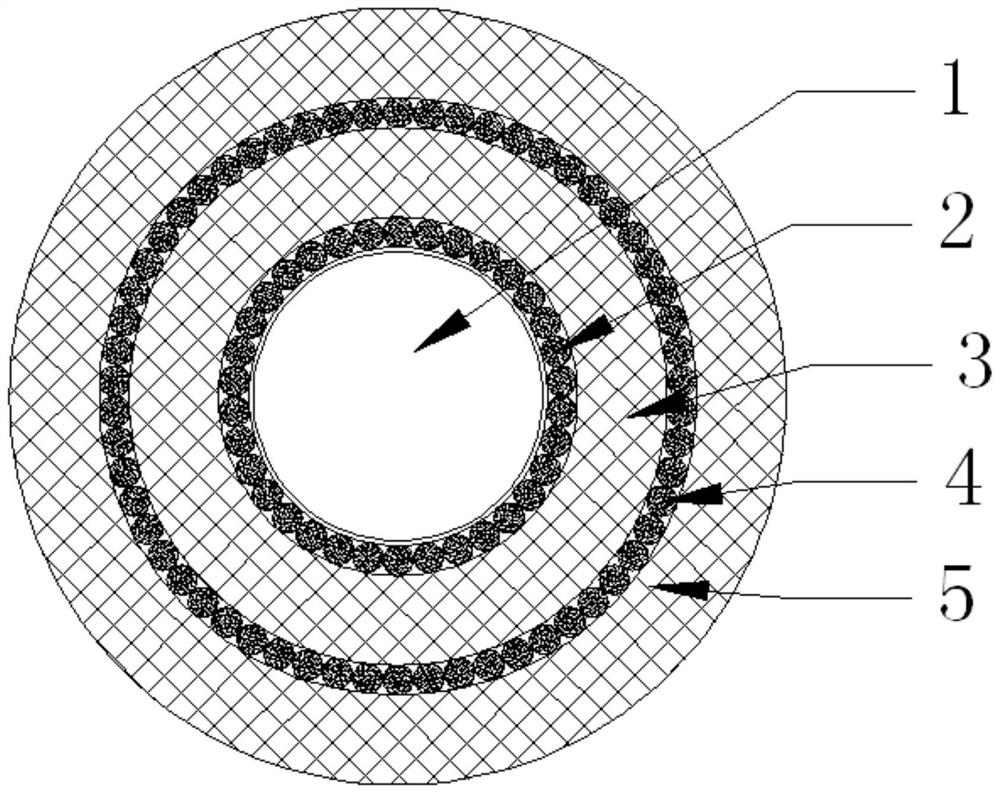

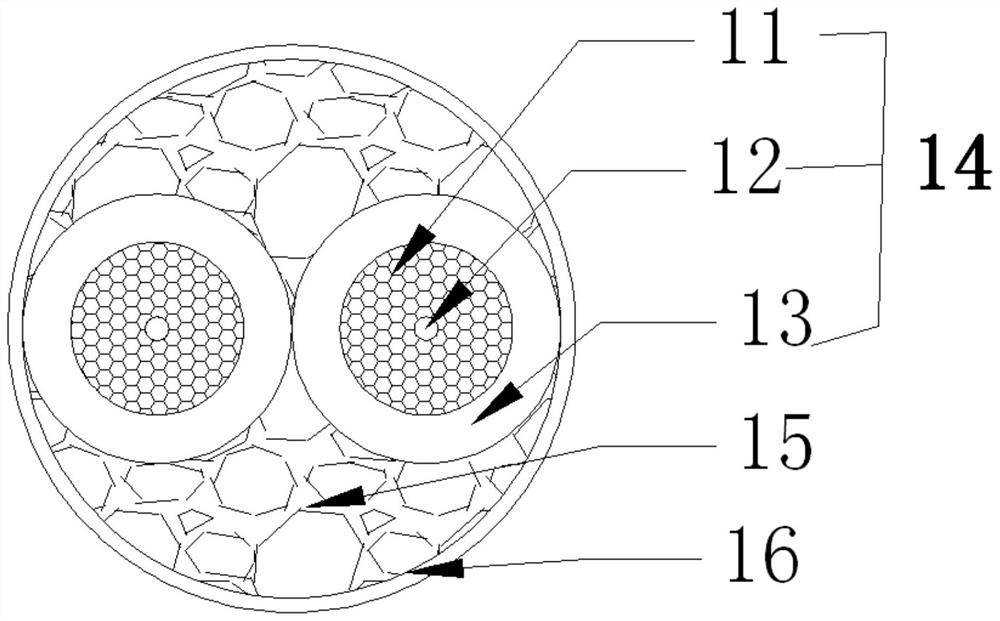

[0022] In order to solve the problem that the twisting times of the cable used by the robot arm in the prior art is insufficient, affecting production efficiency and even causing accidents, the present invention proposes a torsion-resistant robot arm cable, through two layers of aramid filament winding layer to provide the bending of the entire cable The torsion acts as a speed bump, so that the torsional stress of the outer layer is gradually weakened when it is transmitted to the cable core, so that the cable can achieve the purpose of torsion resistance.

[0023] It should be noted that when a component is referred to as being “fixed on” or “disposed on” another component, it may be directly or indirectly located on the other component. When an element is referred to as being "connected to" another element, it can be directly or indirectly connected to the other element. The terms "upper", "lower", "left", "right", "front", "rear", "vertical", "horizontal", "top", "bottom",...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com