Sauce target manufacturing device

A technology for manufacturing devices and sauce targets, which is applied in the field of manufacturing devices, can solve the problems of low manufacturing qualification rate, cumbersome operation procedures, low work efficiency and the like, and achieves the effects of high qualification rate, simple operation procedures and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

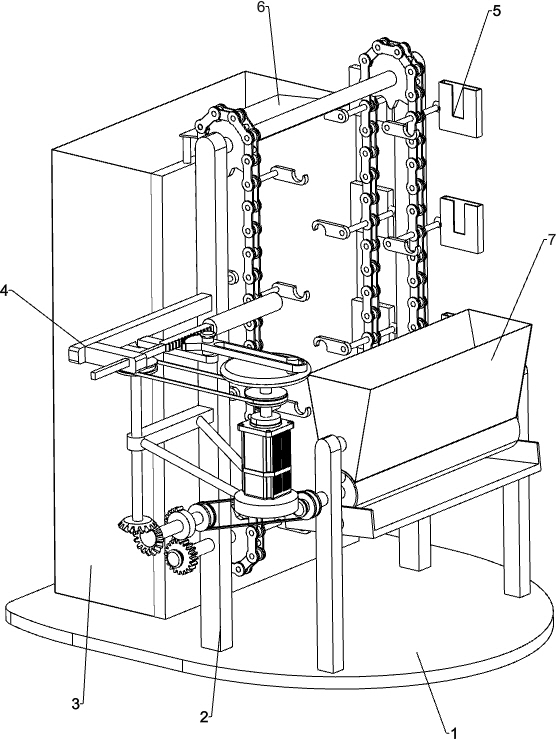

[0042] A sauce target manufacturing device, such as figure 1 As shown, it includes a base 1, a first bracket 2, a collection frame 3, a pressing mechanism 4, a feeding mechanism 5, a baffle plate 6 and a blanking mechanism 7, and the first bracket 2 is arranged in the middle of the top of the base 1, front and rear. A discharge mechanism 5 is connected between the first supports 2, and a compression mechanism 4 is connected between the parts in the discharge mechanism 5 and the top of the first support 2 on the front side. The left side of the top of the base 1 is provided with a collection frame 3, and the collection frame 3. A baffle plate 6 is provided on the right side of the top, and a blanking mechanism 7 is connected between the right side of the top of the base 1 and the components in the discharging mechanism 5.

[0043] When the sauce target needs to be installed, the staff first places a plurality of long handles in the parts in the unloading mechanism 7, then place...

Embodiment 2

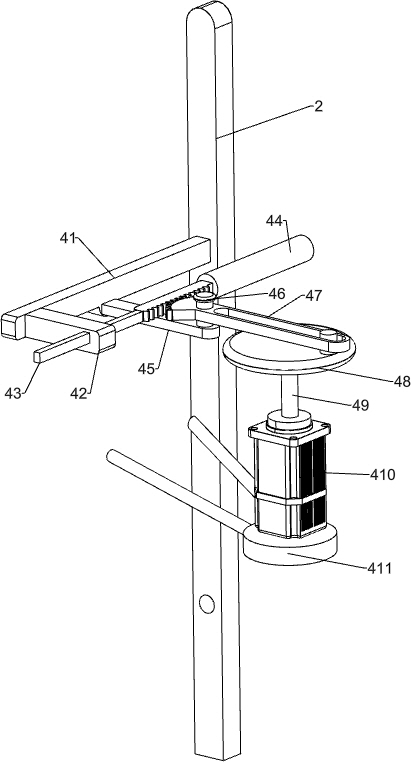

[0045] On the basis of Example 1, such as figure 2 As shown, the pressing mechanism 4 includes a mounting bracket 41, a first sliding sleeve 42, a rack 43, an extruding rod 44, a first connecting rod 45, a fixed column 46, a gear rod 47, a disc 48, and a first rotating shaft 49 , the motor 410 and the mounting base 411, the front side of the first bracket 2 top front side is provided with a mounting frame 41, the right side of the mounting frame 41 front is provided with a first sliding sleeve 42, the first sliding sleeve 42 is slidably connected with a rack 43, the rear end of the rack 43 is provided with an extrusion rod 44, the bottom of the mounting frame 41 is provided with a first connecting rod 45, the first connecting rod 45 is located below the rack 43, and the top right side of the first connecting rod 45 is provided with a fixed column 46. The right side of the discharging mechanism 5 is provided with a mounting seat 411, and the top of the mounting seat 411 is p...

Embodiment 3

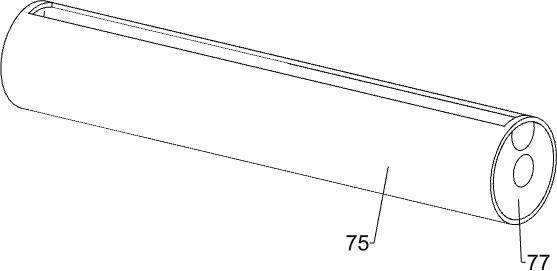

[0048] On the basis of Example 2, such as image 3 As shown, the discharge mechanism 5 includes a first transmission assembly 51, a second rotating shaft 52, a first bevel gear 53, a second bevel gear 54, a rotating column 55, a half gear 56, a spur gear 57, a second sliding sleeve 58, The second connecting rod 59, the chain 510, the hook 511 and the plank frame 512, the lower front side of the first support 2 on the front side is provided with a second sliding sleeve 58, and the front portion of the second sliding sleeve 58 is slidably connected with the second rotating shaft 52, The first transmission assembly 51 is rotatably connected between the top of the second rotating shaft 52 and the middle part of the first rotating shaft 49 , the bottom of the second rotating shaft 52 is provided with a first bevel gear 53 , and the lower part of the front side of the first bracket 2 is rotatably connected with Rotation column 55, the rotation column 55 is located below the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com