External hanging type cavity for cleaning arm stained with organic solution and cleaning method

An organic solution and plug-in technology, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the waste of effective running time of equipment, wafers cannot use vacuum arms, equipment transmission is unstable, etc. problem, to achieve the effect of increasing effective running time, avoiding parameter adjustment and equipment loss, and reducing equipment error reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

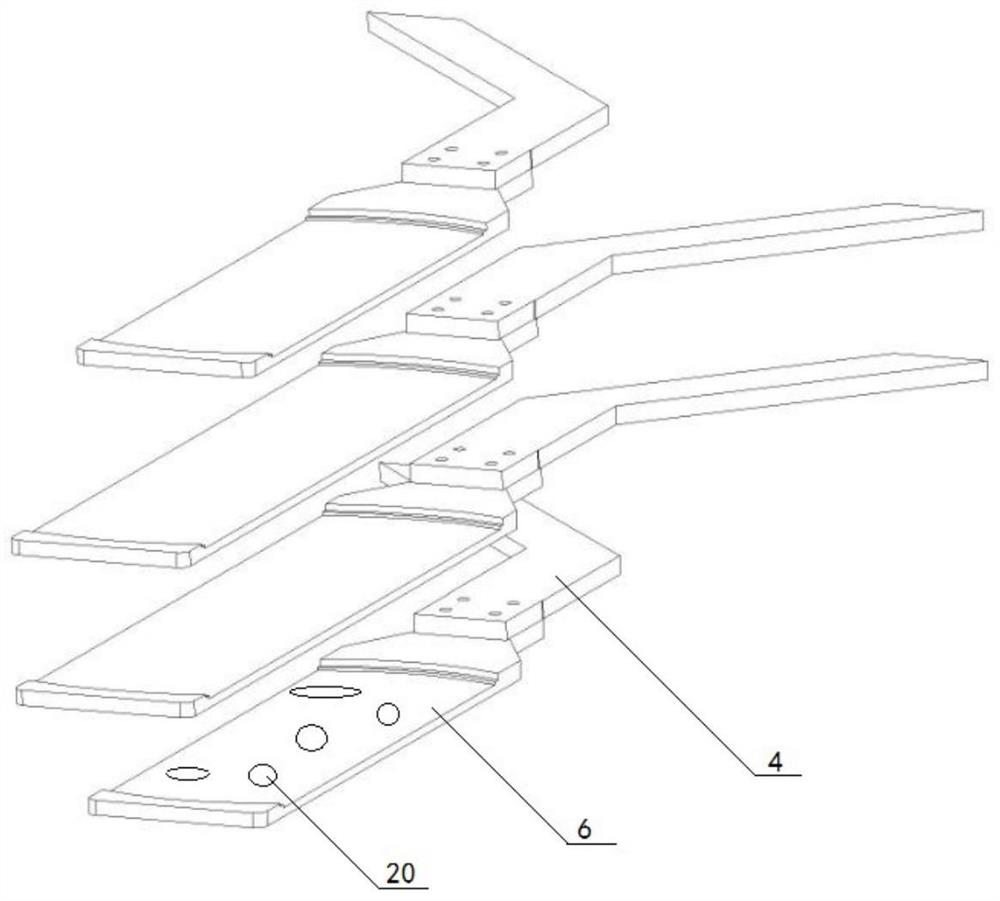

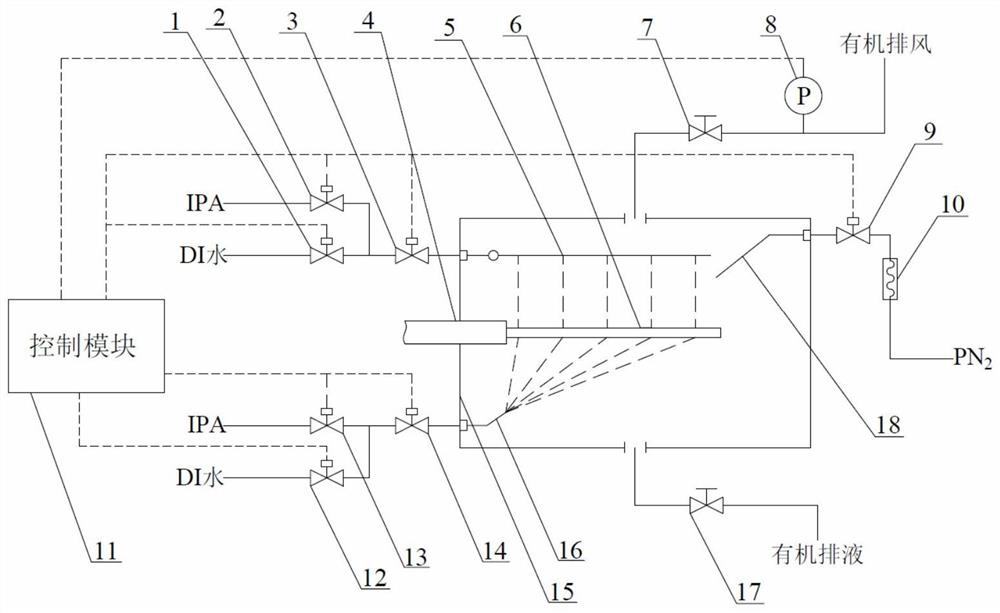

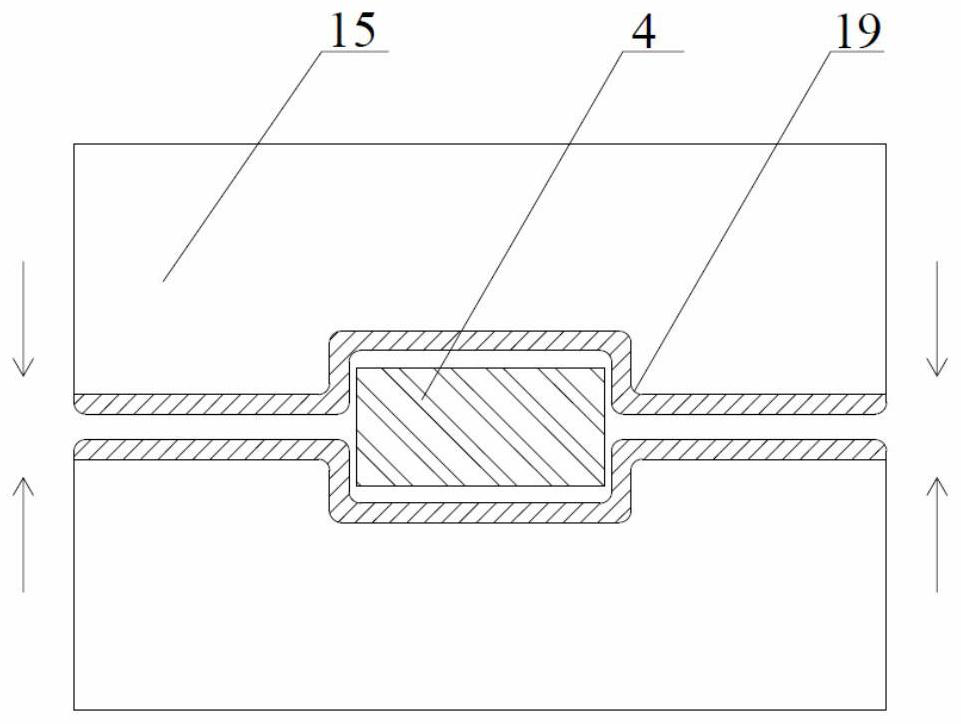

[0044] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] The present invention has designed a kind of external hanging cavity that cleans the arm that is stained with organic solution, as figure 2 As shown, it includes a pipeline for spraying isopropanol on the front, a pipeline for spraying deionized water on the front, a pipeline for spraying isopropanol on the back, a pipeline for spraying deionized water on the back, and a pipeline for hot water Nitrogen drying of lines, doors and control modules. The pipeline for spraying isopropanol on the front side and the pipeline for spraying deionized water on the front side spray isopropanol and deionized water to the front of the arm to be cleaned respectively, and the pipeline and the backside spray isopropanol on the back side The pipeline for spraying deionized water sprays isopropanol and deionized water to the back of the arm to be clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com