Method for preparing composite gel with easy-to-eat characteristic based on high-pressure shear induction

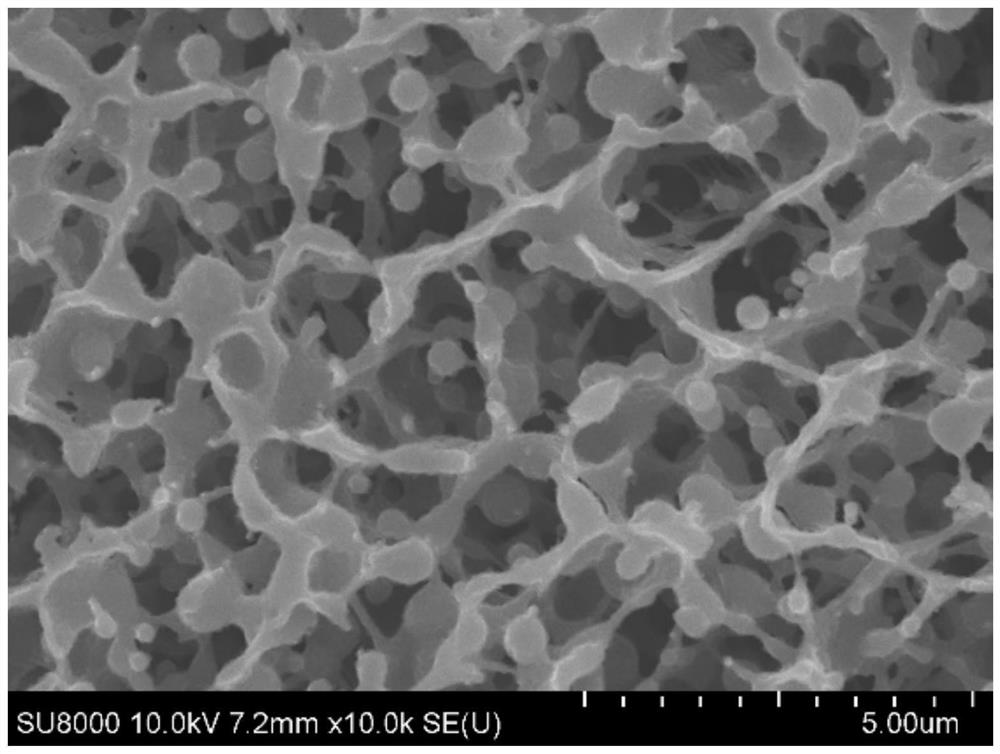

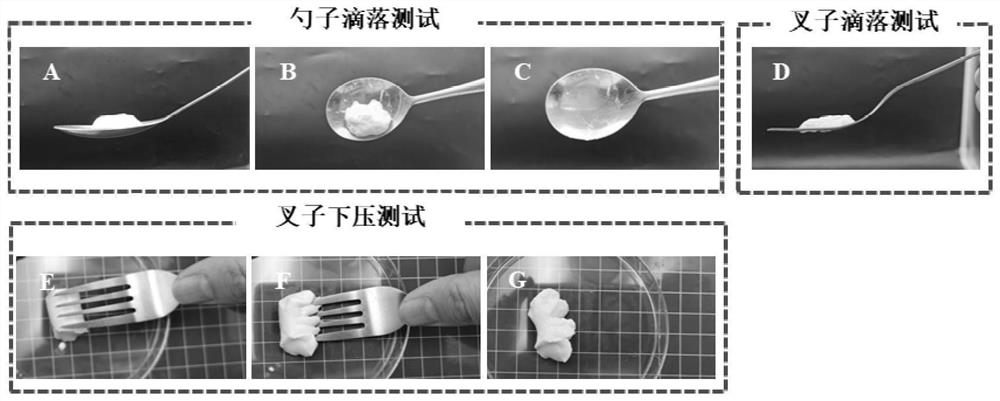

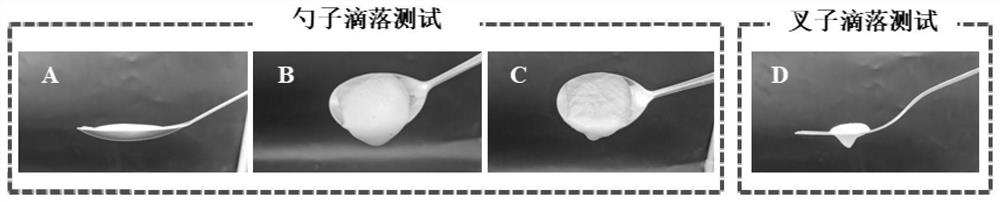

A high-pressure shearing and composite gel technology, applied in the field of food processing, can solve the problems of low gel strength, unstable functional active substances, etc., and achieve the effects of improving water-locking capacity, increasing gel production, and overcoming poor swallowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] S1, ripening: take the thawed cod minced meat and heat it for ripening to obtain cooked fish;

[0067] S2, fish meat prefabrication: mix the cooked fish meat obtained in step S1 with a 0.1% NaCl solution according to a material-to-liquid ratio of 1:50 (g / mL), rinse 5 times at 60° C. for 1 min each time, and pass the rinse mixture through a 60 mesh Nylon filter cloth to filter prefabricated fish;

[0068] S3, the nutritional regulation of fish meat-based: the prefabricated fish meat described in step S2 is mixed with water, inulin and soybean dietary fiber to obtain a composite material, wherein the mass ratio of prefabricated fish meat, water, inulin and soybean dietary fiber is 1kg: 1.4 kg: 160g: 70g;

[0069] S4. Functionalization of oils: Mix linseed oil and carotenoids in a mass ratio of 1kg:0.01g to obtain functional oils;

[0070] S5. One-step emulsion filling-protein cross-linking: subject the compound material described in step S3 to high-pressure shearing tre...

Embodiment 2

[0075] S1, ripening: take the thawed cod minced meat and heat it for ripening to obtain cooked fish;

[0076] S2, fish meat prefabrication: the cooked fish meat obtained in step S1 is mixed with 0.1% NaCl solution according to the material-liquid ratio of 1:50 (g / mL), rinsed 5 times at 60°C for 1 min each time, and the mixture is passed through 80 mesh nylon Filter cloth to obtain prefabricated fish meat;

[0077] S3, the nutritional regulation of fish-based: the prefabricated fish described in step S2 is mixed with water, inulin and soybean dietary fiber to obtain a composite material, and the mass ratio of described prefabricated fish, water, inulin and soybean dietary fiber is 1kg: 1.4kg: 120g: 120g;

[0078] S4. Functionalization of oils: Mix linseed oil and carotenoids in a mass ratio of 1kg:0.01g to obtain functional oils;

[0079] S5. One-step emulsion filling-protein cross-linking: subject the compound material described in step S3 to high-pressure shearing treatment...

Embodiment 3

[0085] S1, ripening: take the thawed cod minced meat and heat it for ripening to obtain cooked fish;

[0086] S2, fish meat prefabrication: the cooked fish meat obtained in step S1 is mixed with 0.1% NaCl solution according to the material-liquid ratio of 1:100 (g / mL), rinsed 3 times at 60° C. for 3 minutes each time, and the mixture is passed through 60 mesh nylon Filter cloth to obtain prefabricated fish meat;

[0087] S3, the nutritional regulation of fish meat-based: the prefabricated fish meat described in step S2 is mixed with water to obtain a composite material, and the mass ratio of the prefabricated fish meat and water is 1kg: 1.4kg;

[0088] S4. One-step emulsion filling-protein cross-linking: subject the compound material described in step S3 to high-pressure shearing treatment, and add linseed oil during the high-pressure shearing treatment process to obtain a composite gel: the pressure is 40MPa, and each 100g compound The corresponding high-pressure shearing tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com