Melt-blown fabric analyzing, cutting and forming device

A forming device and structure technology, which is applied in the field of melt-blown cloth analysis and cutting and forming devices, can solve the problems of many mechanical failures, inability to cut melt-blown cloth, and large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

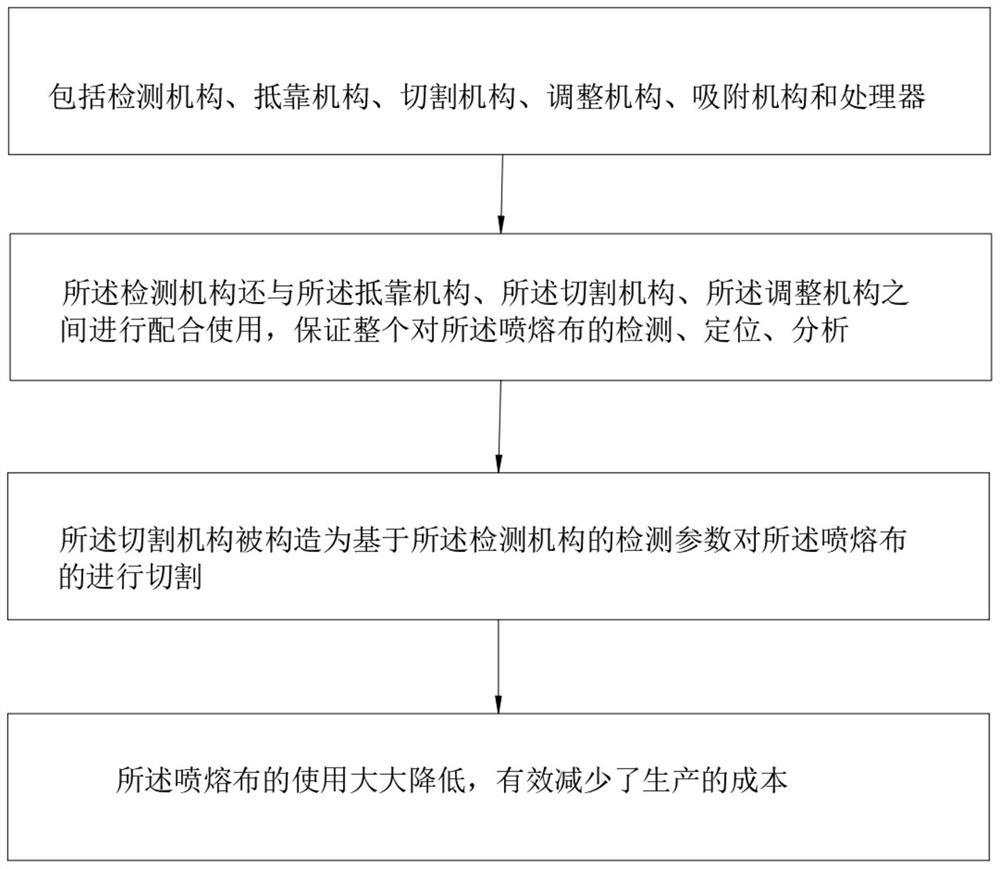

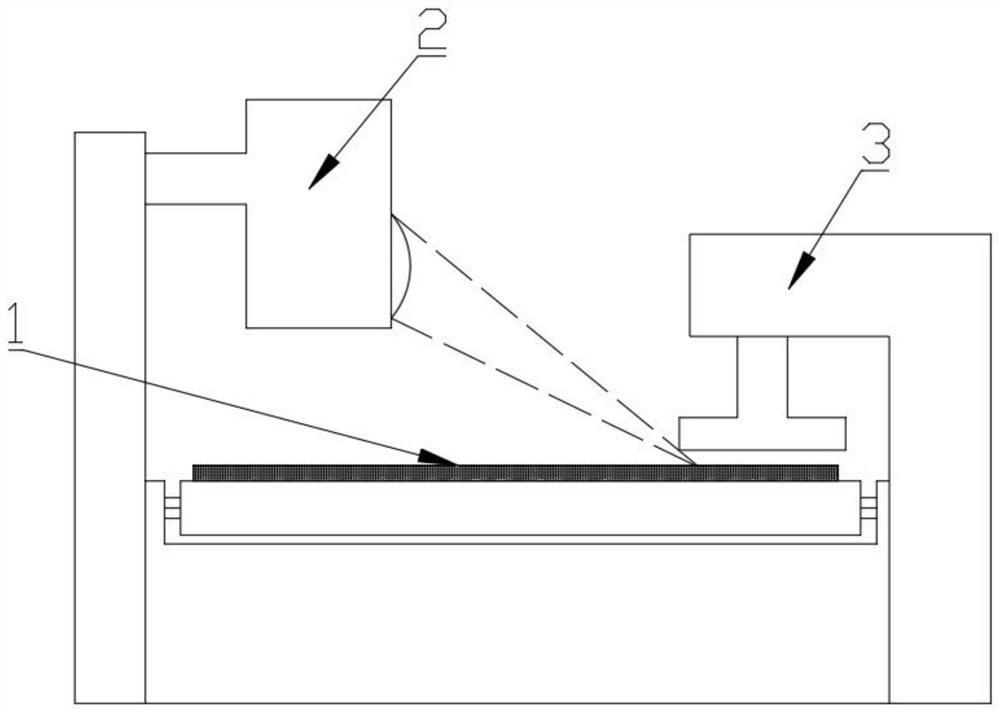

[0035] Embodiment 1: An analysis and cutting forming device for melt-blown cloth 1, including a detection mechanism 2, an abutment mechanism, a cutting mechanism 10, an adjustment mechanism 3, an adsorption mechanism and a processor. The detection mechanism 2 is configured to The size and position of the melt-blown cloth 1 is detected; the cutting mechanism 10 is configured to cut the melt-blown cloth 1 based on the detection parameters of the detection mechanism 2; the adjustment mechanism 3 is configured to The detected parameters of the mechanism 2 adjust the size of the melt-blown cloth 1, and the adsorption mechanism is configured to absorb and transfer the cut melt-blown cloth 1; the detection mechanism 2 includes a detection unit and an auxiliary unit, The detection unit is configured to collect the size and shape of the melt-blown cloth 1, and generate action parameters based on the parameters collected by the detection unit; The size of the fused cloth 1 is detected; ...

Embodiment 2

[0036] Embodiment 2: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis thereof. Specifically, an analysis and cutting forming device for melt-blown cloth 1 is provided, including a detection mechanism 2. Abutment mechanism, cutting mechanism 10, adjustment mechanism 3, adsorption mechanism and processor, the detection mechanism 2 is configured to detect the size and position of the melt-blown cloth 1; the cutting mechanism 10 is configured to The detection parameters of the detection mechanism 2 cut the melt-blown cloth 1; the adjustment mechanism 3 is configured to adjust the size of the melt-blown cloth 1 based on the detected parameters of the detection mechanism 2, so The adsorption mechanism is configured to absorb and transfer the cut melt-blown cloth 1; specifically, in this embodiment, the size of the melt-blown cloth 1 to be used is detected by the detectio...

Embodiment 3

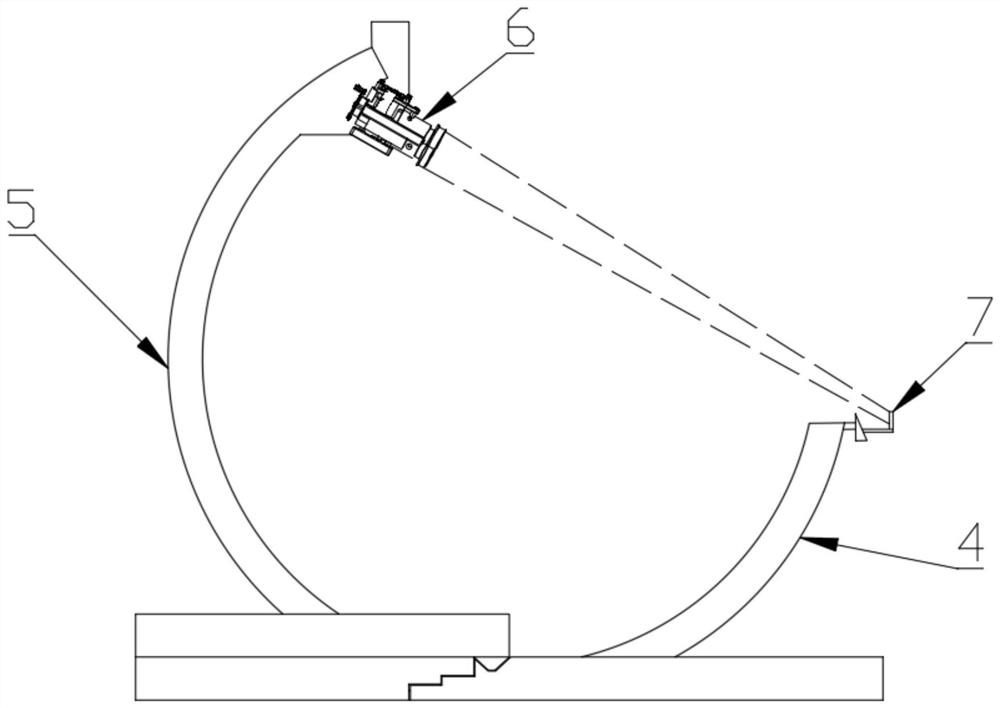

[0043] Embodiment 3: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis thereof. Specifically, a detection mechanism 2 is provided, and the detection mechanism 2 includes a detection unit and An auxiliary unit, the detection unit is configured to collect the size and shape of the melt-blown cloth 1, and generate action parameters based on the parameters collected by the detection unit; The size of the melt-blown cloth 1 is detected; the auxiliary unit includes a rotating member, a reference piece 7 and a first driving mechanism, the first driving mechanism is configured to drive the rotating member, and the reference piece 7 It is configured to cooperate with the detection operation of the rotating member and the detection unit; specifically, the detection mechanism 2 is configured to analyze and detect the melt-blown cloth 1, and in the detection process, it needs t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com