Grinding device and grinding method for automobile brake pad machining

A technology of brake pads and automobiles, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of low clamping efficiency, poor uniform effect, and poor use effect, so as to achieve easy clamping and clamping stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

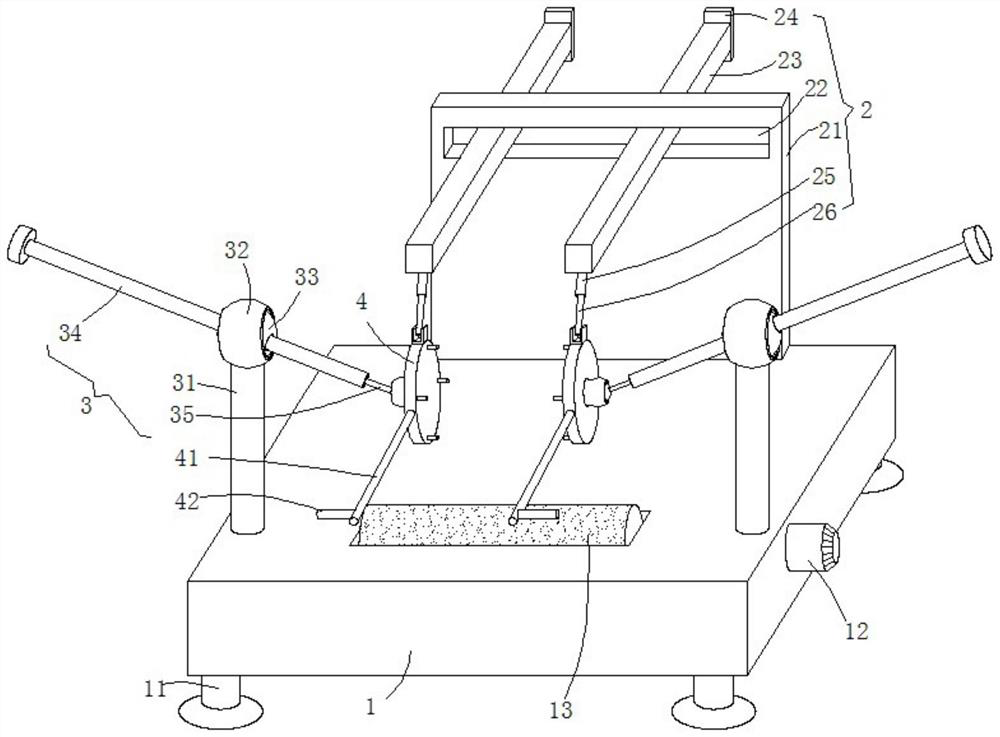

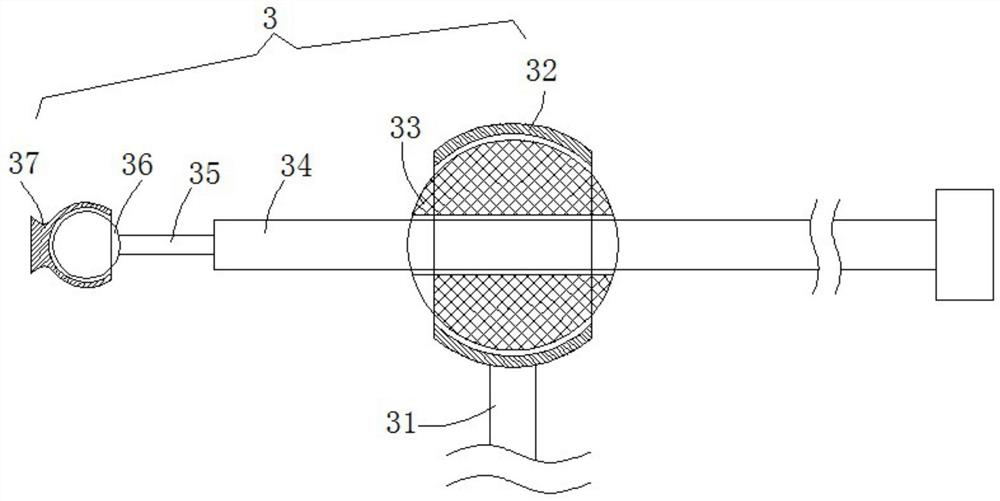

[0025] see Figure 1-2 , the present embodiment provides a grinding device and grinding method for the processing of automobile brake pads, including a base 1, two clamping mechanisms 3, a guide mechanism 2 and two clamping discs 4, the top end of the base 1 is set in the middle of the front side There is a rotation placement groove, and a grinding roller 13 is rotated between the side walls of the inner cavity of the rotation placement groove, and the highest point of the radial side wall of the grinding roller 13 exceeds the top end surface of the base 1 by 3 cm, and the right end surface of the base 1 is fixed. There is a driving motor 12, the driving motor 12 extends to the inner cavity of the rotating placement groove through the rotation of the power shaft, and is fixedly connected with the center position of the axial right end surface of the grinding roller 13, and the two clamping mechanisms 3 are distributed on the left and right, and both include support columns 31....

Embodiment 2

[0031] see Figure 1-2 , further improvements have been made on the basis of Example 1:

[0032] The rear end face of each guide crossbeam 23 is all vertically provided with limit plate 24, and the height of each limit plate 24 is equal to twice of the vertical height of rectangular guide hole 22 inner cavities, is equal to the vertical height of rectangular guide hole 22 inner cavities by arranging height The double limit plate 24 can prevent the guide beam 23 from detaching from the inner cavity of the rectangular guide hole 22 .

[0033] The radial side walls of the two clamping discs 4 all extend forward with operating rods 41, and the side walls on the side where the tips of the two operating rods 41 are far away from each other extend horizontally with handles 42. Hold the handles 42 with both hands, and then pass Two operating rods 41 remotely operate the clamping disc 4 to drive the brake pads of the automobile to adjust the position and perform grinding operation at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com