A thermal shock preparation method and application of multi-principal alloy nanoparticles

A multi-principal alloy and nanoparticle technology, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of complex components of multi-principal alloy hydrogen storage alloys, uneven distribution of particle elements and sizes, and unavoidable problems. Intermetallic compound precipitation and other problems, to achieve the advantages of excellent hydrogen storage kinetic performance, uniform structure, and the effect of improving kinetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Composition design of multi-principal alloy nanoparticles.

[0037] This embodiment is a multi-principal element hydrogen storage alloy TiZr nanoparticle composed of two elements, Ti and Zr.

[0038] 2. Preparation of multi-principal alloy nanoparticles.

[0039] The preparation of multi-principal alloy nanoparticles is the most critical step, and the preparation process is as follows:

[0040] 1) Raw material preparation: Weigh the metal salts of the two elements Ti and Zr respectively (titanocene dichloride C 10 h 10 Cl 2 Ti, titanium zirconium acetylacetonate C 20 h 28 o 4 Zr), the present embodiment selects the salt as high-purity (purity is more than 97%); It is respectively 10ml of dehydrated ethanol salt solution that configuration two kinds of metal salt concentrations are 0.025mol / l.

[0041] 2) Mixed solution: Take equal volumes (1ml each) of prepared salt solutions, add them to a centrifuge tube and mix them, place them in an ultrasonic cleaner for ...

Embodiment 2

[0053] 1. Difference description.

[0054] This embodiment synthesizes multi-principal element hydrogen storage alloy TiZrHfNb nanoparticles, the specific implementation is the same as Example 1, the difference is that the raw material is a salt of Ti, Zr, Hf and Nb (titanocene dichloride C 10 h 10 Cl 2 Ti, titanium zirconium acetylacetonate C 20 h 28 o 4 Zr, hafnium tetrachloride Cl 4 Hf and niobium pentachloride Cl 5 Nb); the concentrations of the four metal salts are 0.0125 mol / l; the synthesis time is 5s.

[0055] 2. Characterization of multi-principal alloy nanoparticles.

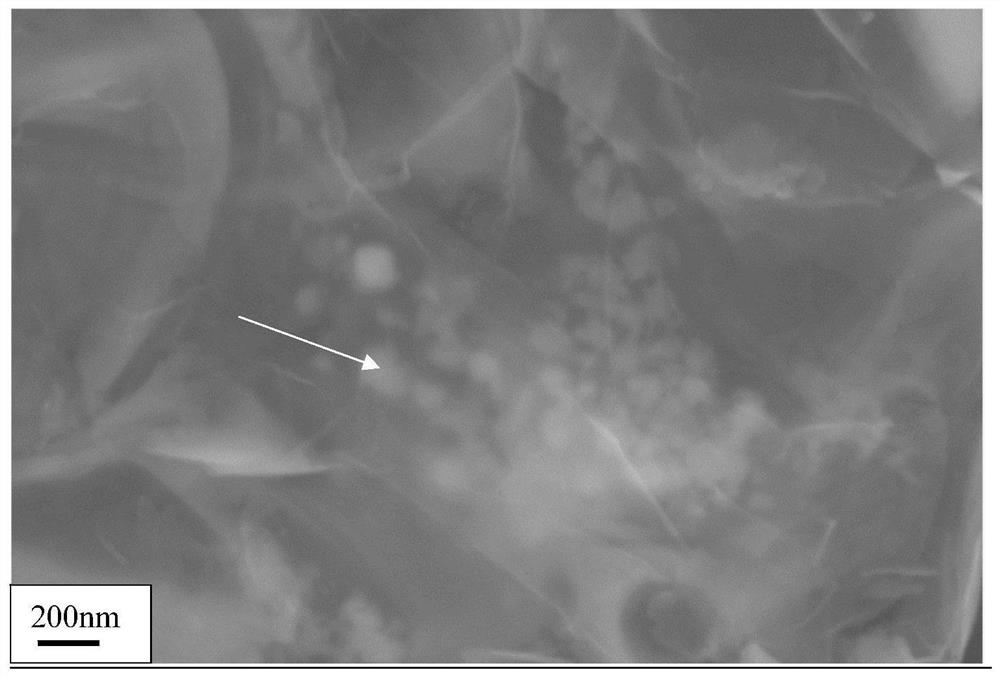

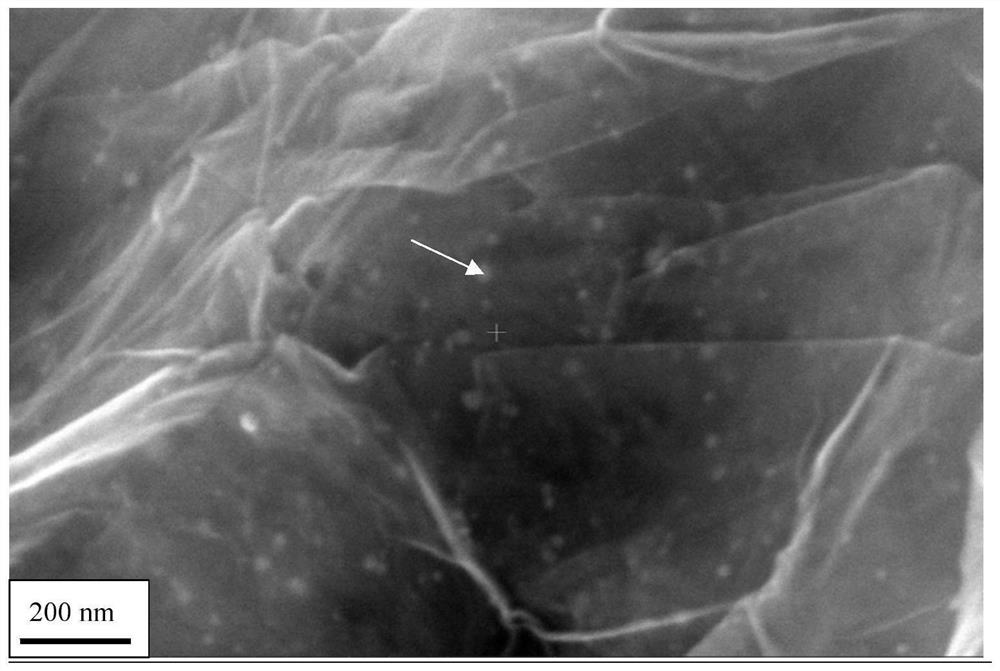

[0056] 1) Scanning electron microscope morphology analysis

[0057] Select a single crystal silicon with a suitable size, ultrasonically clean it (cleaning sequence is acetone, deionized water, absolute ethanol) in the air, and add an appropriate amount of absolute ethanol (make Graphene has good dispersibility), the graphene solution (>10μl) was dropped on the single crystal silicon, dried by...

Embodiment 3

[0064] 1. Difference description.

[0065] This embodiment synthesizes TiZrHfMoNb nanoparticles of a multi-principal element hydrogen storage alloy. 10 h 10 Cl 2 Ti, titanium zirconium acetylacetonate C 20 h 28 o 4 Zr, hafnium tetrachloride Cl 4 Hf, molybdenum chloride ClMo and niobium pentachloride Cl 5 Nb); the concentrations of the five metal salts are 0.0125mol / l; the synthesis time is 15s.

[0066] 2. Characterization of multi-principal alloy nanoparticles.

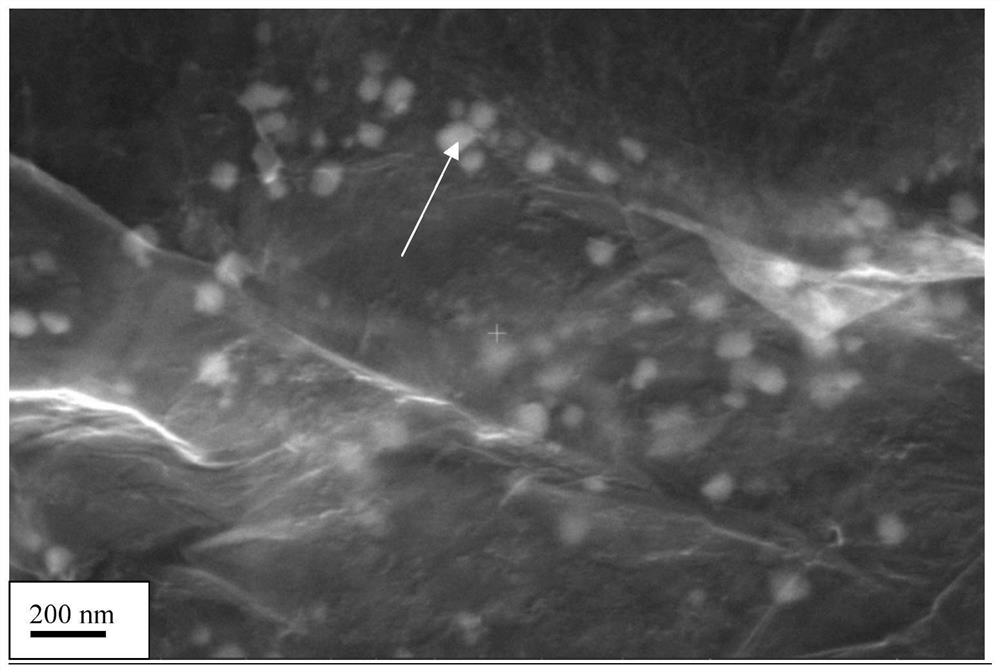

[0067] 1) Scanning electron microscope morphology analysis

[0068] Select a single crystal silicon with a suitable size, ultrasonically clean it (cleaning sequence is acetone, deionized water, absolute ethanol) in the air, and add an appropriate amount of absolute ethanol (make Graphene has good dispersibility), the graphene solution (>10μl) was dropped on the single crystal silicon, dried by an ultraviolet heating lamp, and the morphology of the sample was observed with a scanning electron microscope. Dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com