Prefabricated brick moulding bed mortise and tenon joint structure and construction method

A tire mold tenon and tenon joint structure technology, applied in infrastructure engineering, construction and other directions, can solve problems such as landslides, long construction time, and potential safety hazards, and achieve the effects of strong rigidity, fast construction speed, and strong construction structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

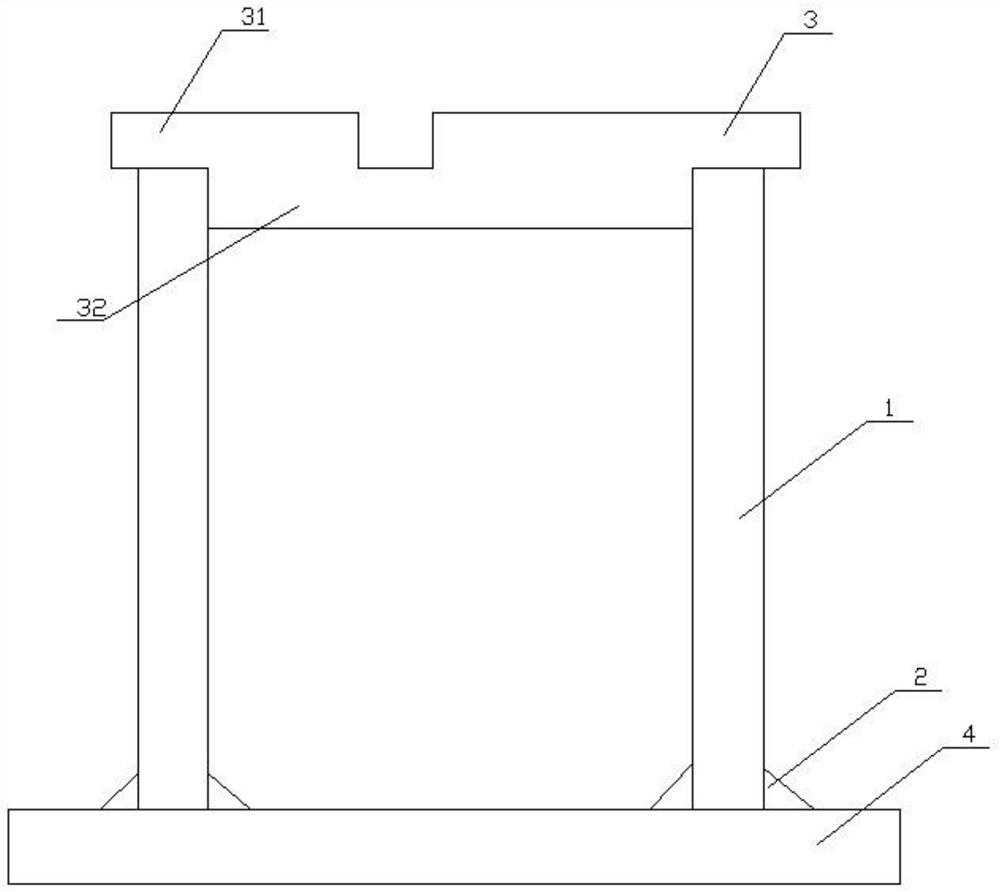

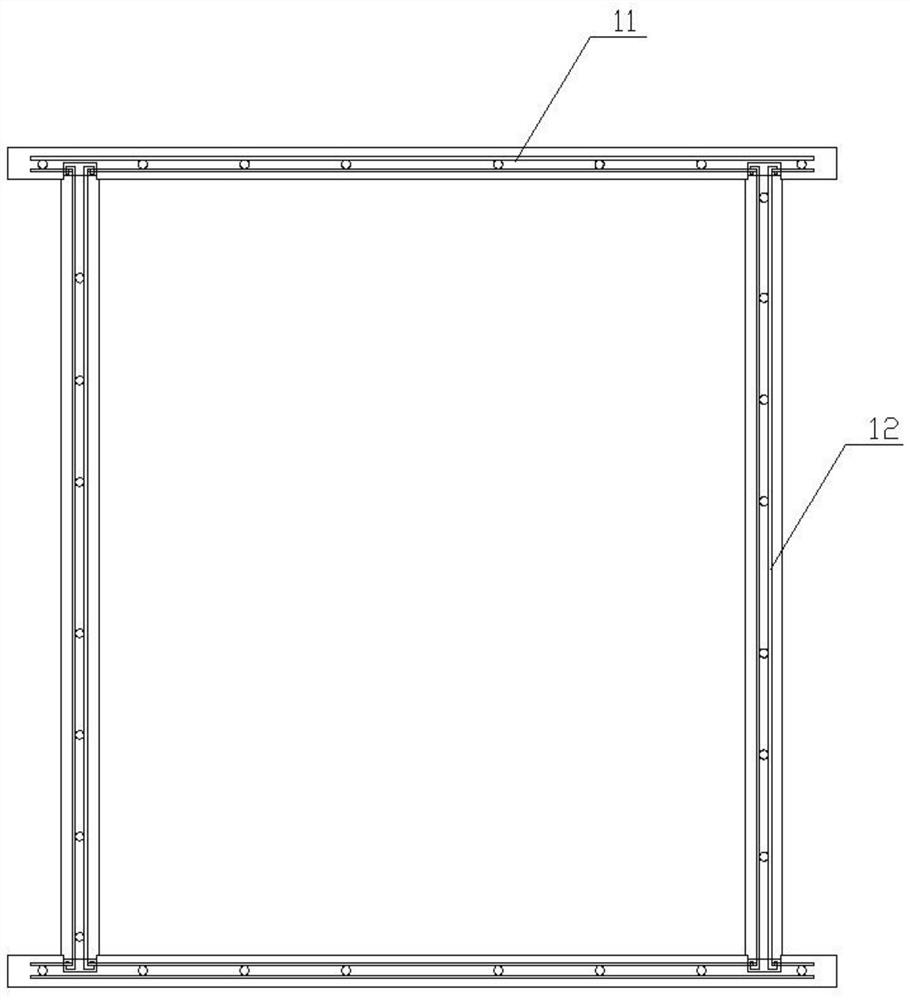

[0035] Such as figure 1 as shown, figure 1It is the structural front view of the prefabricated brick tire mold mortise and tenon connection structure; the prefabricated brick tire mold mortise and tenon connection structure of the present invention includes a prefabricated plate group 1, a bottom support assembly 2 and a central support assembly 3, and the prefabricated plate group 1 It includes a number of prefabricated panels, the formwork frame is formed by placing the prefabricated panels on the base plate 4, and the bottom of the prefabricated panels is fixedly connected with the base plate 4 through the bottom support assembly 2, which is used to strengthen the prefabricated panels. The connection state of the board and the bottom board 4, the central support assembly 3 is arranged between the prefabricated boards in the prefabricated board group 1, and is used to fix the position state between the prefabricated boards, thereby forming a stable formwork construction stru...

Embodiment 2

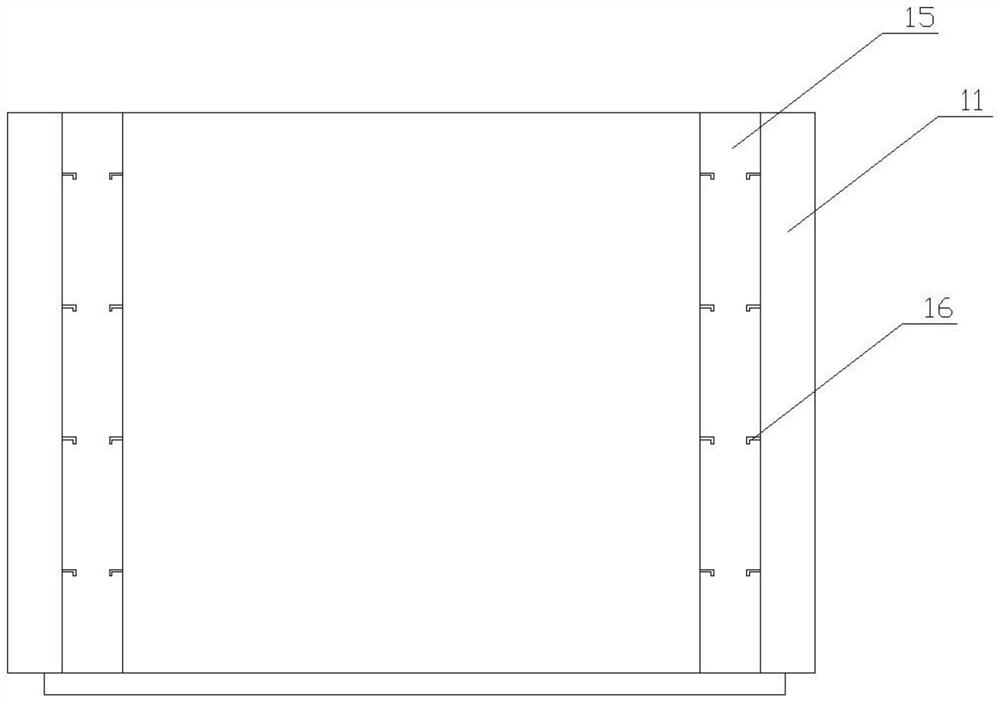

[0051] The first prefabricated panel 11, the second prefabricated panel 12, the third prefabricated panel 13, and the fourth prefabricated panel 14 are all provided with structural steel bars, and the first connecting member 16 and the second prefabricated panel The connectors 18 are formed by extending the structural steel bars.

[0052] Specifically, the structural steel bars include main steel bars 111 and reinforcing steel bars 112, and the main steel bars 111 are arranged as multiple parallel and vertical straight steel bars or multiple rectangular steel bar frames according to the thickness of the prefabricated slab.

[0053] When it is set as a plurality of straight steel bars, the straight steel bars are all set at equal distances.

[0054] Such as Figure 5 as shown, Figure 5 It is a top view of the connection structure of the first prefabricated panel and the second prefabricated panel in the state of the main steel bar of the straight steel bar; on the first pref...

Embodiment 3

[0065] The construction method of the prefabricated brick tire mold mortise and tenon joint structure comprises the steps of:

[0066] S1, completing the construction of the base plate 4, and forming the fixing groove on the base plate 4;

[0067] S2, sequentially installing the prefabricated panels to form a formwork frame;

[0068] S3, installing the bottom support assembly 2 and the center support assembly 3;

[0069] S4, filling the connection cavity by pouring;

[0070] S5, backfilling the periphery of the formwork frame;

[0071] S6, dismantling the central support assembly 3 and performing main body pouring work.

[0072] In the step S2, when constructing a separate rectangular cross-section cap or ground beam, the second prefabricated panel 12 is first installed on the corresponding position of the bottom plate 4 according to the fixing groove, and the When the first prefabricated slab 11 is described, the first prefabricated slab 11 is lifted away from the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com