Excavator bucket follow-up control system and method

A technology for excavators and buckets, which is applied in the field of excavator bucket follow-up control systems, can solve problems such as large differences in bucket leveling, observation visual errors, and material spillage, so as to improve material handling efficiency and avoid leveling Deviation, the effect of reducing material spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

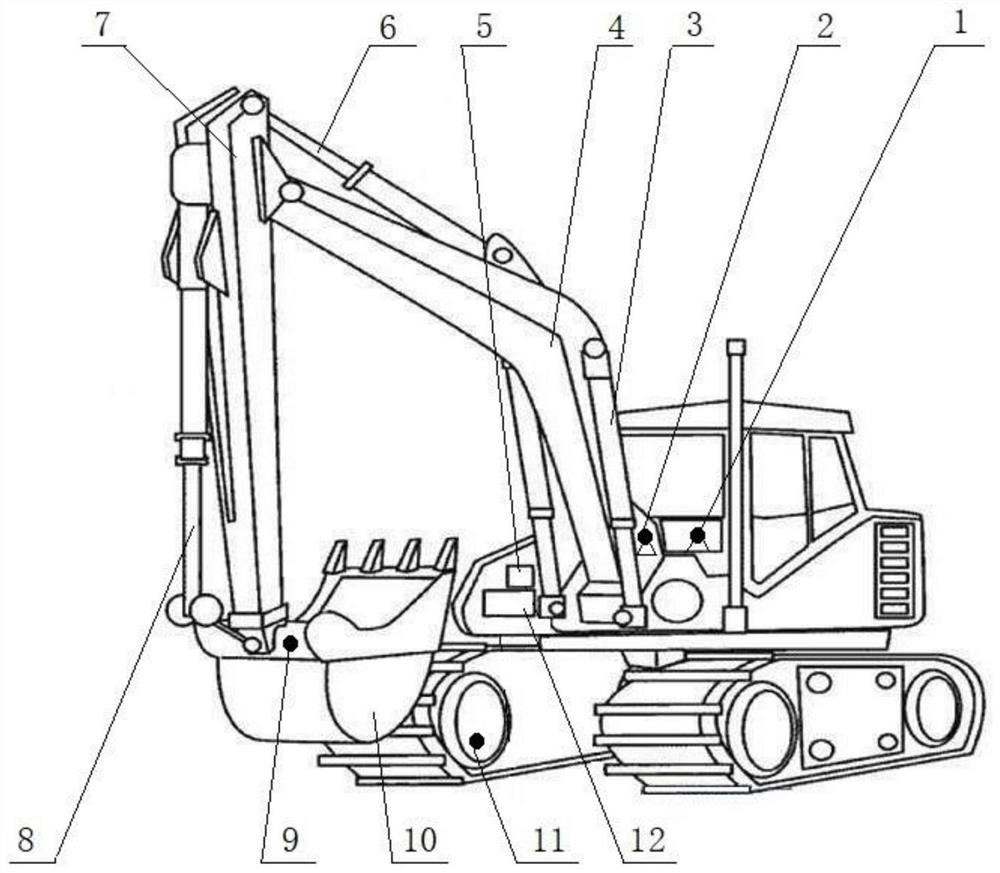

[0029] Such as figure 1 As shown, the present invention includes a boom cylinder 3 and a stick cylinder 6 arranged on the excavator, wherein the boom cylinder 3 is connected with the boom 4, the end of the boom 4 is connected with a stick 7, and the top of the stick 7 is connected with the stick The oil cylinder 6 is connected, the bottom is connected with a bucket 10, and a bucket oil cylinder 8 is installed on one side of the stick 7. The excavator is equipped with a vehicle-mounted controller 5 and a hydraulic valve group 12. The driver's compartment of the excavator is equipped with joysticks, including a left joystick 1 and a right joystick 2. A vehicle speed sensor 11 is installed on the driving chain of the excavator. 10 is connected with an inclination sensor 9, wherein the inclination sensor 9, the vehicle speed sensor 11 and the operating handle are all connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com