Color-changing wear-resistant myopic lens, production method and glasses

A technology for myopic lenses and production methods, which are applied in the directions of glasses/goggles, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of low strength, poor visual effect, and easy scratching of myopic lenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

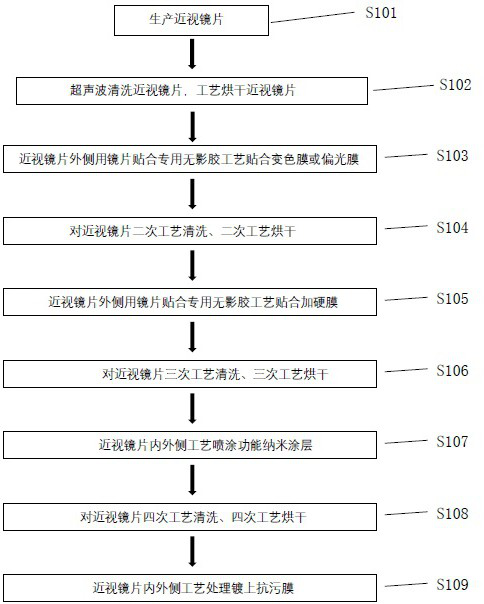

[0055] The invention provides a method for producing a color-changing wear-resistant myopia lens, comprising:

[0056] Step 1: producing myopia lenses;

[0057] Step 2: The myopia lens is soaked in the cleaning solvent, the myopia lens is cleaned by ultrasonic equipment, and the surface of the myopia lens is dried by drying equipment;

[0058] Step 3: Spray glue on the outer surface of the myopia lens, send the color-changing film or polarizing film into the myopia lens station with automatic film lamination equipment, and quickly press and paste, and remove the synthetic myopia lens from the automatic film lamination equipment;

[0059] Step 4: The synthetic myopia lens is soaked in the cleaning solvent for the second time, the synthetic myopia lens is cleaned by ultrasonic equipment for the second time, and the surface of the myopia lens is dried twice by the drying equipment;

[0060] Step 5: Spray the special shadowless glue for lens lamination on the outer surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com