Green process for exploiting combustible ice

A green process and interface technology, applied in the field of green process, can solve the problems of easy condensation of heat source fluid and low mining cost, and achieve the effects of low mining cost, improving mining efficiency and enhancing mass transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

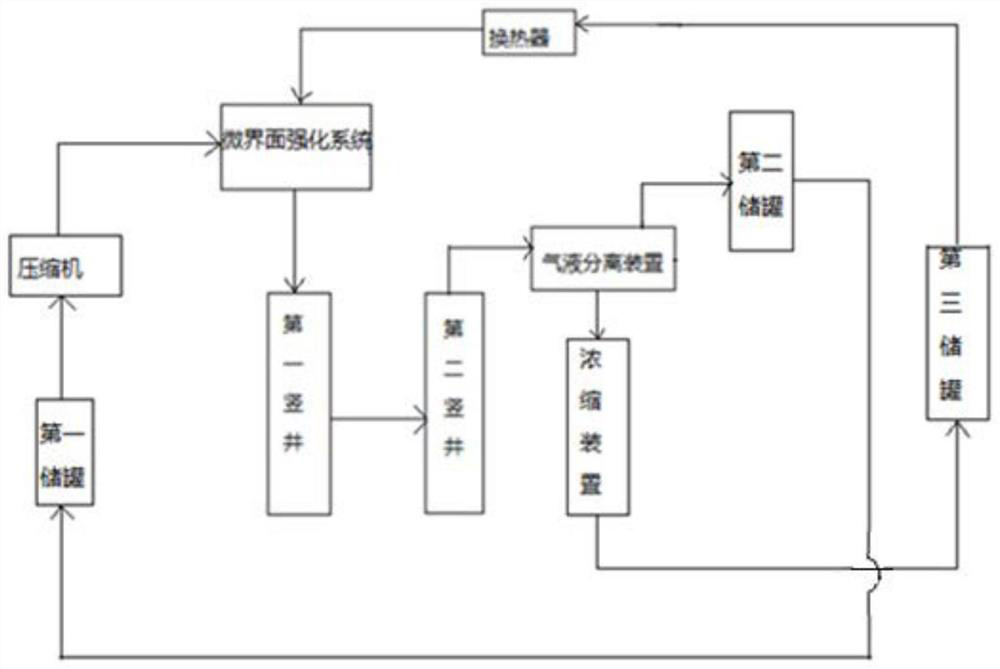

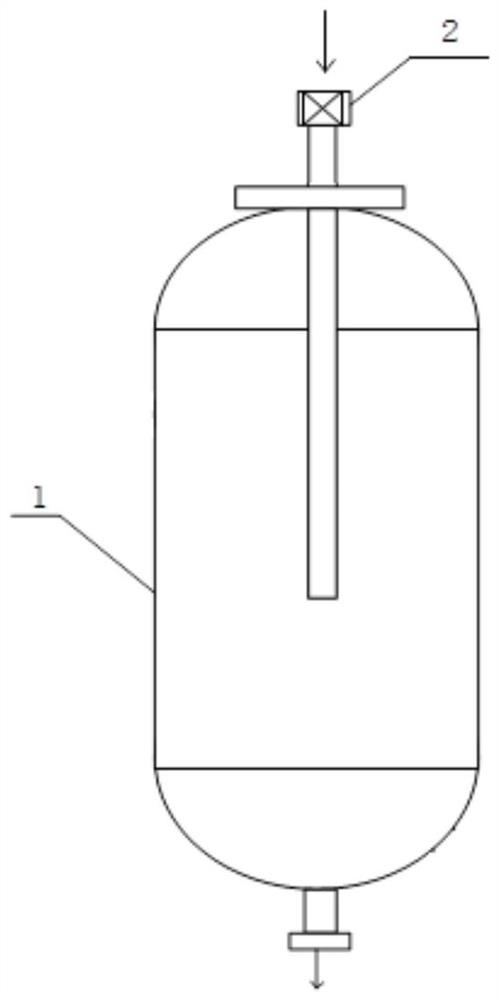

[0040] Such as figure 1 , figure 2 Shown, a kind of green technology of exploiting combustible ice of the present invention comprises the following steps:

[0041] S1, the natural gas in the first storage tank is pressurized into the micro-interface strengthening device through the compressor, and the pressure in the compressor is 10Mpa;

[0042] S2, the seawater concentration device prepares seawater into saturated brine and enters the heat exchanger, and is heated to 100°C by the heat exchanger and enters the micro interface strengthening device;

[0043] S3, natural gas and saturated brine are mixed through the micro-interface strengthening device to form micro-bubbles and / or micro-droplet emulsions. The gas-liquid volume ratio fed into the micro-interface strengthening device is 10:1. By adjusting the ratio of gas-liquid mixing, it can Regulate the ratio of gas-liquid mixing, and regulate the temperature range of the freezing point in the first shaft to -30°C;

[0044]...

Embodiment 2

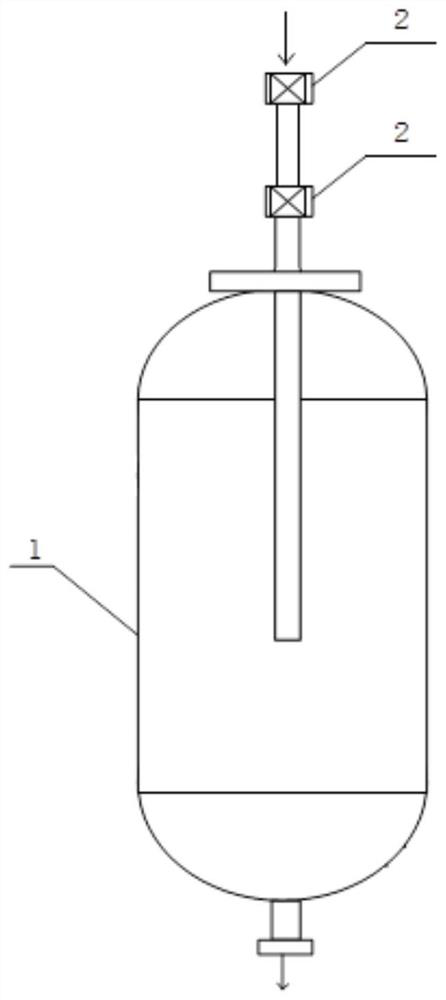

[0049] Such as figure 1 , image 3 Shown, a kind of green technology of exploiting combustible ice of the present invention comprises the following steps:

[0050] S1, the natural gas in the first storage tank is pressurized into the micro-interface strengthening device through the compressor, and the pressure in the compressor is 15Mpa;

[0051] S2, the seawater concentration device prepares seawater into saturated brine and enters the heat exchanger, and is heated to 120°C by the heat exchanger and enters the micro interface strengthening device;

[0052] S3, natural gas and saturated brine are mixed through the micro-interface strengthening device to form microbubbles and / or micro-droplet emulsions. The gas-liquid volume ratio of the micro-interface strengthening device is 200:1. By adjusting the ratio of gas-liquid mixing, it can Regulate the ratio of gas-liquid mixing, and regulate the temperature range of the freezing point in the first shaft to -45°C;

[0053]The mic...

Embodiment 3

[0058] Such as figure 1 , figure 2 Shown, a kind of green technology of exploiting combustible ice of the present invention comprises the following steps:

[0059] S1, the natural gas in the first storage tank is pressurized into the micro-interface strengthening device through the compressor, and the pressure in the compressor is 10Mpa;

[0060] S2, the seawater concentration device prepares seawater into saturated brine and enters the heat exchanger, and is heated to 100°C by the heat exchanger and enters the micro interface strengthening device;

[0061] S3, natural gas and saturated brine are mixed through the micro-interface strengthening device to form microbubbles and / or micro-droplet emulsions. The gas-liquid volume ratio of the micro-interface strengthening device is 500:1. By adjusting the ratio of gas-liquid mixing, it can Regulate the ratio of gas-liquid mixing, and regulate the temperature range of the freezing point in the first shaft to -55°C;

[0062] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com