Anti-backlash gear structure

A technology of gear structure and anti-backlash, which is applied in the direction of gear transmission, belt/chain/gear, gear vibration/noise attenuation, etc. It can solve the problems of large guiding length and large structural size of the gear shaft, and achieve less friction pairs and smaller size. Small, to ensure the effect of eliminating the gear meshing gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

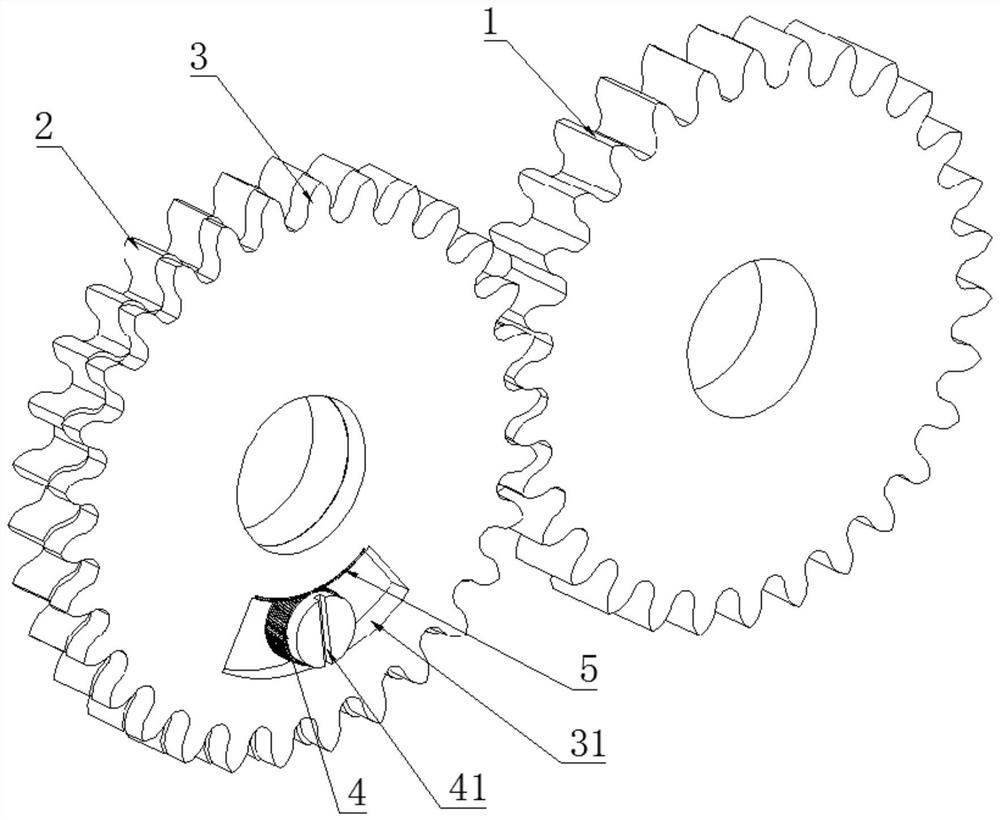

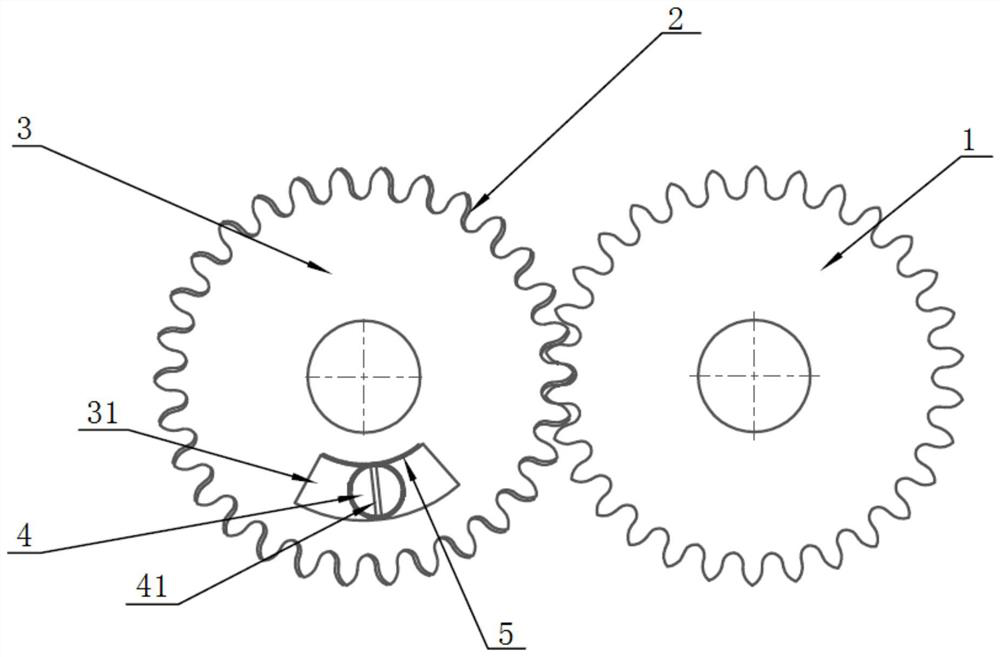

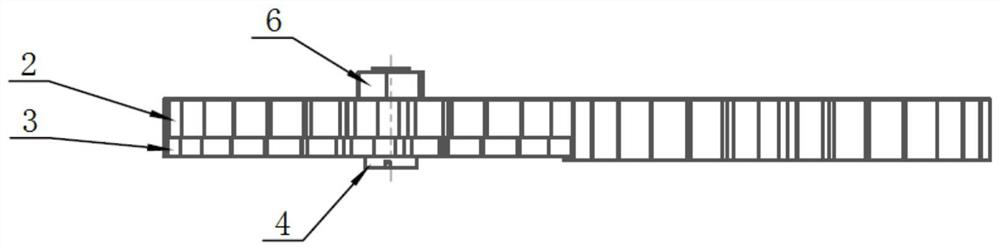

[0028] The specific embodiment of the present invention is like this: with reference to Figure 1-6 As shown, an anti-backlash gear structure includes a driving gear 1 and a first anti-backlash gear 2 meshed with the driving gear 1. One end of the first anti-backlash gear 2 is provided with a second anti-backlash gear 3 that can rotate coaxially. The second anti-backlash gear 3 is provided with a worm gear structure 5, and the first anti-backlash gear 2 is provided with a rotatable worm structure 4, and one end of the worm structure 4 is provided with helical teeth matched with the spiral teeth of the turbine structure 5, The other end of the worm structure 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com