Grain drying device

A technology of grain drying and drying box, which is applied to grain drying, drying, dryer and other directions, can solve problems such as low drying efficiency, and achieve the effects of high drying efficiency, prevention of grain leakage detection, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

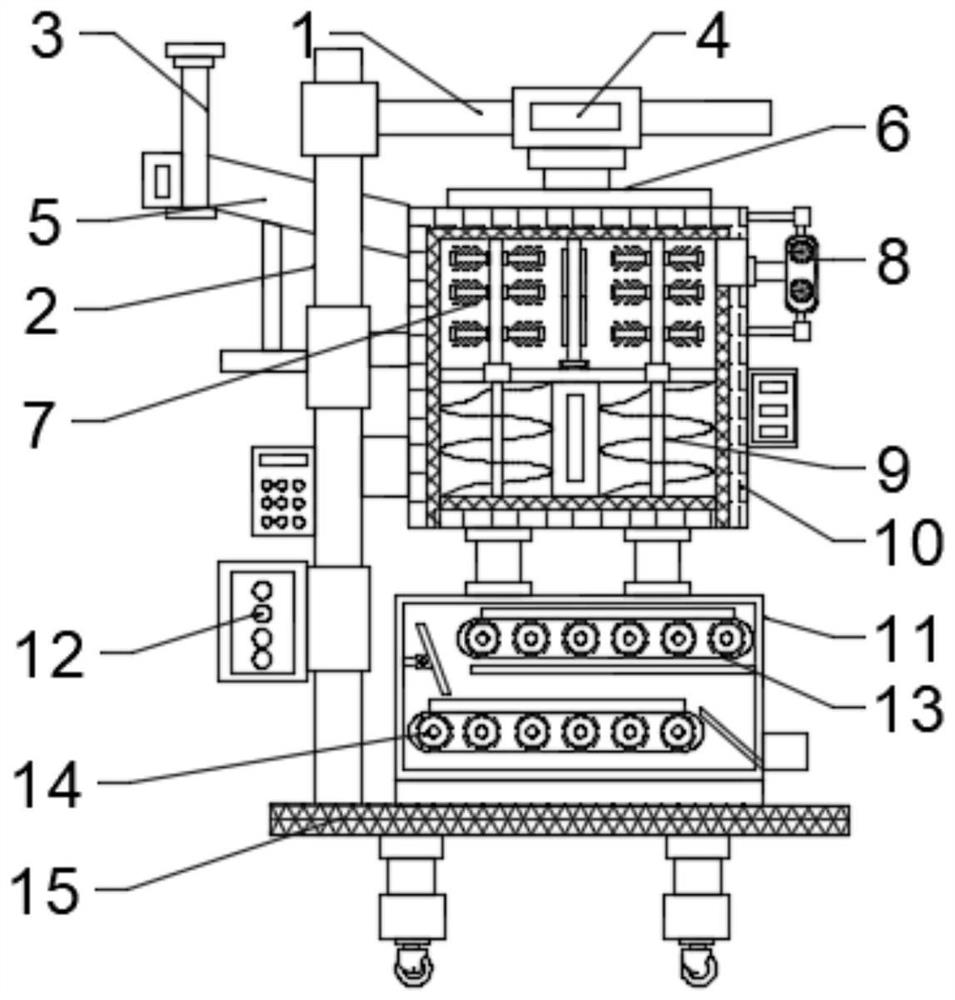

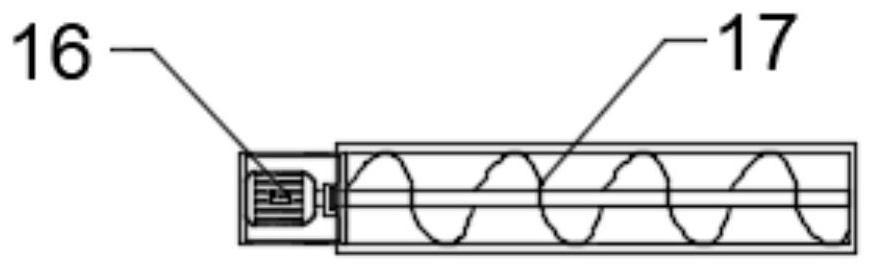

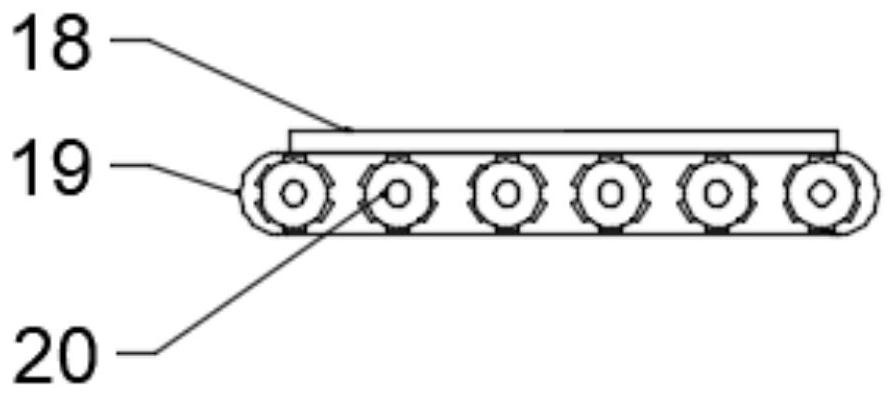

[0022] see Figure 1~4 , in an embodiment of the present invention, a grain drying device includes a mounting frame 2; a top seat 1 is installed on the top of the mounting frame 2; a fixing seat 4 is provided on the top seat 1; The bottom end is connected to the top of the drive mechanism by a hydraulic rod; the bottom end of the drive mechanism is equipped with a stirring paddle 7; the stirring paddle 7 is arranged inside the stirring box 10; Heating layer; the corresponding heating layer on the stirring box 10 is provided with an electronic heater; the bottom of the stirring box 10 is connected to the drying box 11; the inside of the drying box 11 is provided with a transmission drying mechanism; the drying The bottom ends of the box 11 and the installation frame 2 are all installed on the top of the base 15; one side of the stirring box 10 is equipped with a feeding mechanism.

[0023] Further, the feeding mechanism includes a feed pipe 3; the bottom end of the feed pipe 3...

Embodiment 2

[0029] see figure 1 , the bottom of the base 15 is equipped with a moving mechanism; the moving mechanism includes a hydraulic lifting rod; the hydraulic lifting rod is provided with at least four; the bottom of the hydraulic lifting rod is equipped with a lifting box; the lifting box There is a lifting mechanism inside; the bottom end of the lifting mechanism is equipped with a moving wheel; the lifting mechanism can be any type of lifting mechanism in the prior art; through the setting of the lifting mechanism, the moving wheel can be received inside the lifting box , to prevent shaking during drying and affect the efficiency; through the setting of the hydraulic lifting rod, the height of the device can be adjusted, which is convenient to use.

[0030] The working principle of the present invention is: the grain is stirred by the stirring paddle 7, so that the grain is in contact with the heating layer, so that the grain is heated and dried; the height of the stirring paddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com