Inner ruler laying device for vertical metal tank verification and using method

A metal can, vertical technology, applied in the field of vertical metal can verification inner ruler device, can solve the inner circumference of the circle, affect the measurement accuracy, time-consuming and labor-intensive problems, to achieve improved accuracy, simple structure, and moving speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

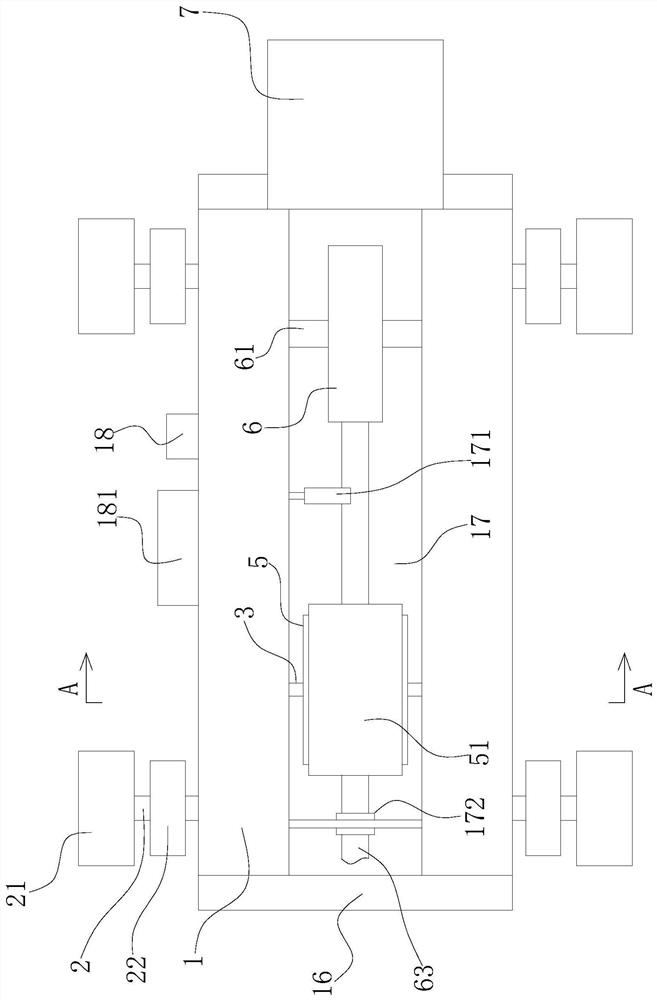

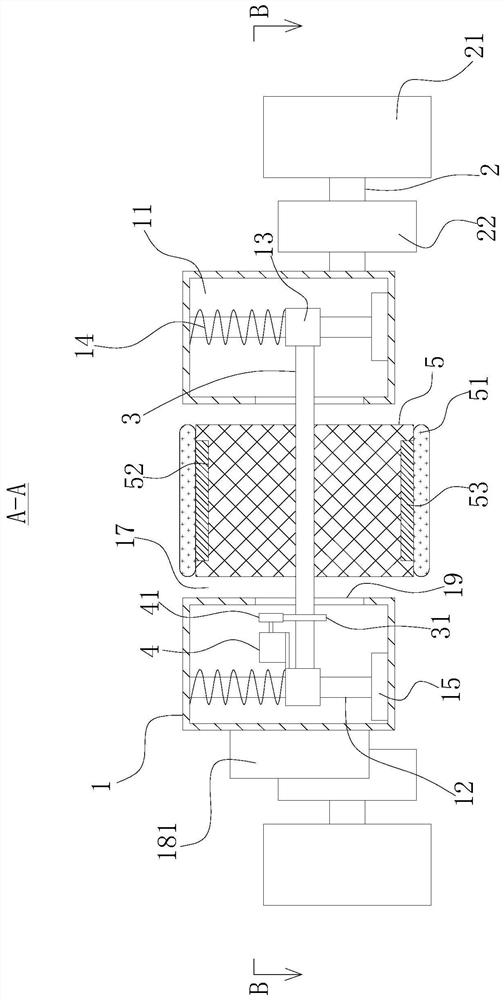

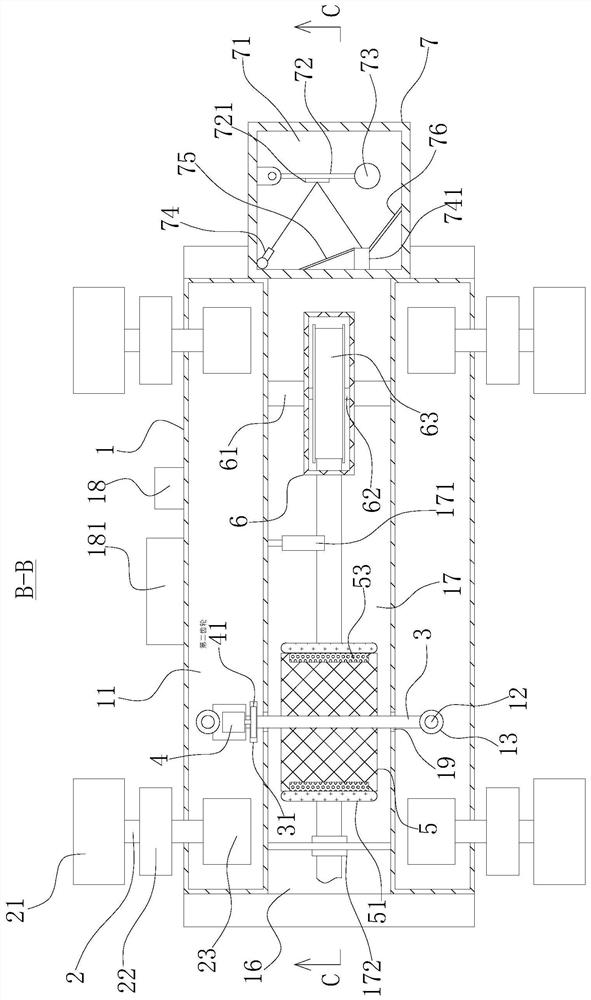

[0060] Such as Figures 1 to 8 As shown, an internal ruler-laying device for vertical metal tank verification, the vertical metal tank includes a tank wall 8, including two installation boxes 1, a first drive mechanism, a cylindrical box 6, and a limiting square tube 172 , Limiting square tube 172 and leveling mechanism.

[0061] The two installation boxes 1 are fixedly connected in parallel by two connecting rods 16, a gap 17 is formed between the two installation boxes 1, and the two connecting rods 16 are respectively arranged on the two installation boxes one after the other. The front and rear ends of box 1.

[0062] The first drive mechanism is arranged on the two installation boxes 1 , and the first drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com