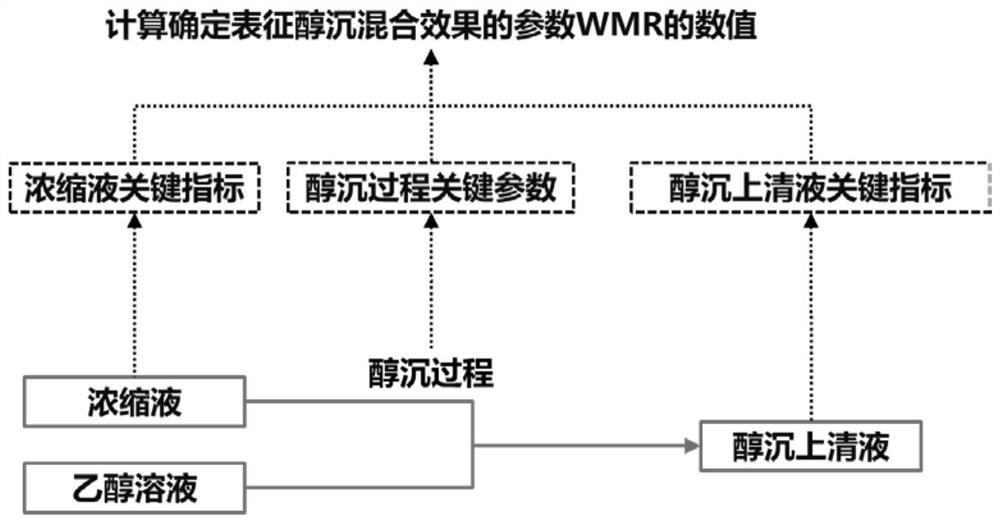

A Method for Quantitatively Evaluating the Mixing Condition of Alcohol Precipitation Process

A quantitative evaluation and alcohol precipitation technology, which is applied in the direction of settling tanks, measuring devices, and material weighing, etc., can solve the problems that there is no method for quantitatively evaluating the mixing effect of ethanol solution and concentrated liquid, and achieve clear physical meaning, low cost, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

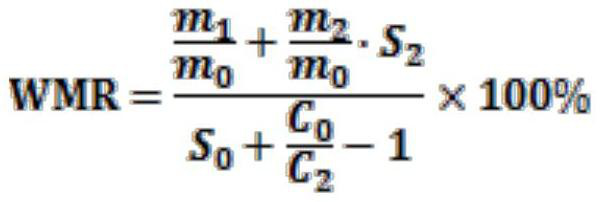

[0020] According to literature research and preliminary experimental results, tangshenoside was selected as the indicator of mixing conditions in Codonopsis pilosula concentrate. Codonopsis pilosula medicinal material is extracted by heating water, concentrated under reduced pressure, concentrated for a period of time to obtain Codonopsis pilosula concentrate, and the solid content of the concentrate obtained after testing is 55%. The content of tangshenoside in the concentrated liquid was detected by liquid chromatography to be 224.06 μg / g. Then use the concentrated solution to carry out stirring alcohol precipitation, the concentrated solution consumption is 41.3g, and the ethanol consumption is 62.0g. Stir for 5 minutes after adding ethanol, and filter to obtain 76.5 g of alcohol precipitation supernatant. After detection, the solid content in the supernatant of alcohol precipitation was 13.34%, and the content of tangshenoside in the supernatant was 72.98 μg / g. The total...

Embodiment 2

[0022] According to literature research and preliminary experimental results, tangshenoside was selected as the indicator of mixing conditions in Codonopsis pilosula concentrate. Codonopsis pilosula is extracted by heating water, concentrated under reduced pressure, concentrated for a period of time to obtain Codonopsis pilosula concentrate, and the solid content of the concentrate obtained after testing is 50%. The content of tangshenoside in the concentrated liquid was detected by liquid chromatography to be 219.34 μg / g. Then use the concentrated solution to carry out membrane dispersion alcohol precipitation, the amount of the concentrated solution is 32.5 g, and the amount of ethanol is 53.9 g. After adding ethanol, stir for 5 minutes, and filter to obtain 74.4 g of alcohol precipitation supernatant. After detection, the solid content in the supernatant of alcohol precipitation was 11.04%, and the content of tangshenoside in the supernatant was 90.93 μg / g. The total amou...

Embodiment 3

[0024] According to literature research and preliminary experimental results, tangshenoside was selected as the indicator of mixing conditions in Codonopsis pilosula concentrate. Codonopsis pilosula is extracted by heating water, concentrated under reduced pressure, concentrated for a period of time to obtain Codonopsis pilosula concentrate, and the solid content of the concentrate obtained after testing is 60%. The content of tangshenoside in the concentrated liquid was detected by liquid chromatography to be 211.30 μg / g. Then use the concentrated solution to carry out membrane dispersion alcohol precipitation, the amount of the concentrated solution is 38.7g, and the amount of ethanol is 64.7g. Stir for 5 minutes after adding ethanol, and filter to obtain 75.7 g of alcohol precipitation supernatant. After detection, the solid content in the supernatant of alcohol precipitation was 7.17%, and the content of tangshenoside in the supernatant was 79.34 μg / g. The total amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com