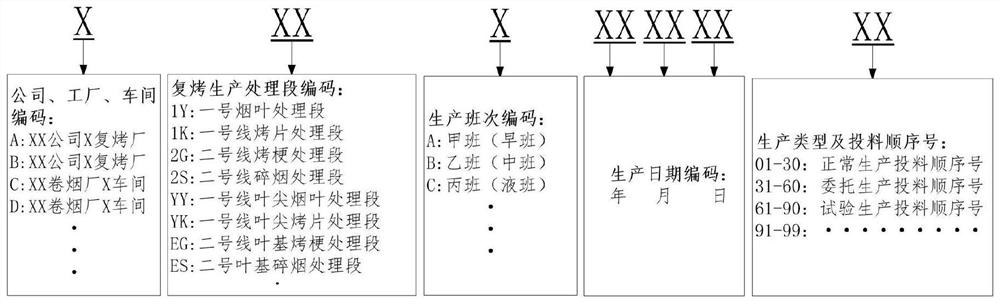

Threshing and redrying production batch encoding method

A technology of producing batches, leaf threshing and re-roasting, which can be applied to other database retrieval, resources, food science, etc., and can solve problems such as unspecified batch coding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

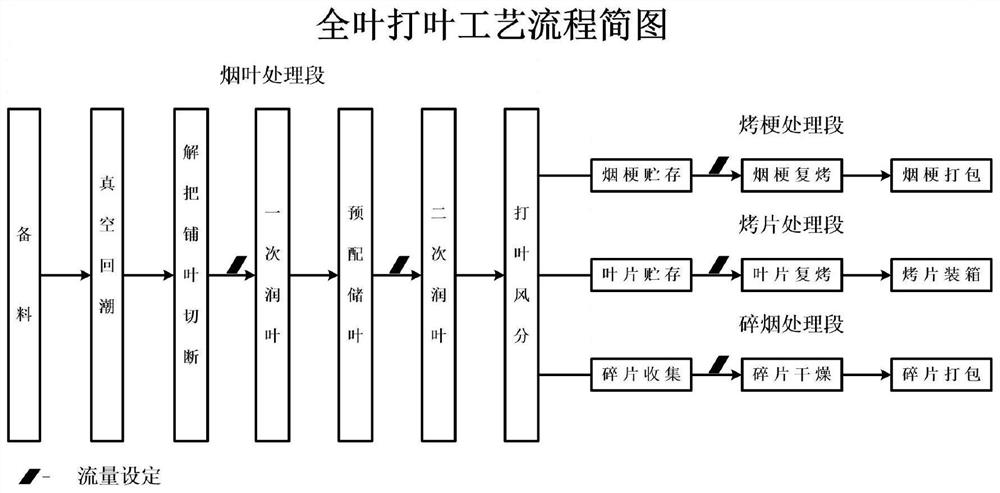

[0026] In order to facilitate those skilled in the art to understand and realize the present invention, the technical solution of the present invention is now further described in conjunction with the drawings and specific embodiments.

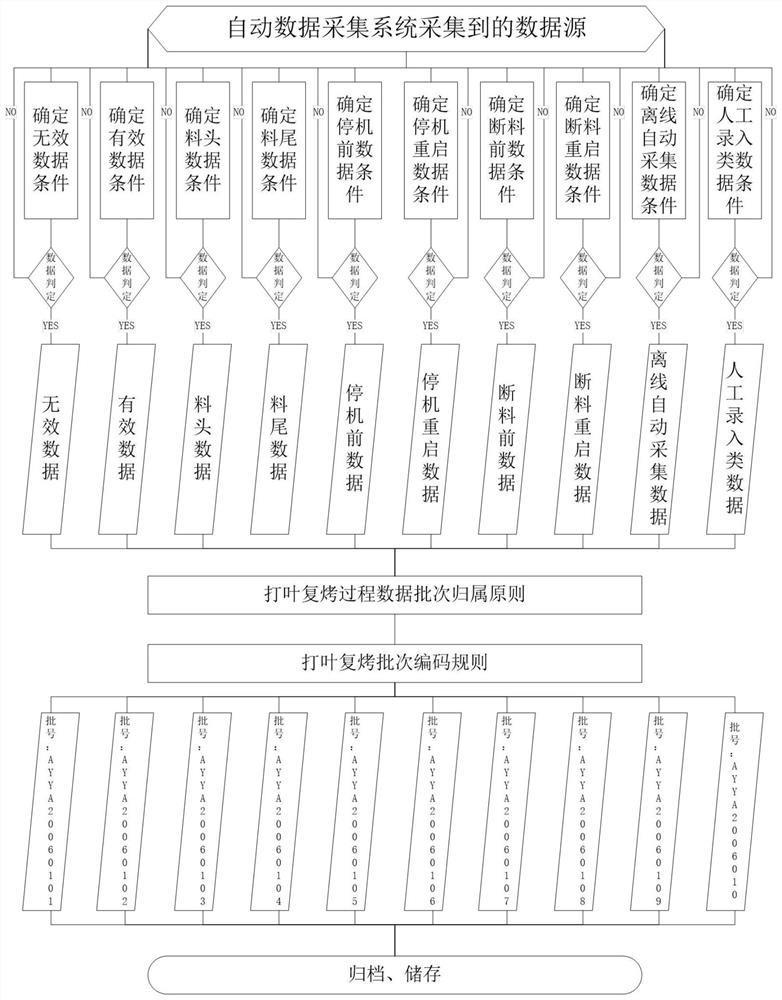

[0027] Determine the automatic data acquisition system and data status identification including: invalid data, valid data, material head data, material tail data, data before shutdown, restart data after shutdown, data before cutoff, restart data after cutoff, offline automatic data collection, manual entry Class data, etc.; determine the collection data, data status identification.

[0028] Determine invalid data: Process data collected under the state of no material passing through is used as invalid data, and the status of this type of data is identified.

[0029] Determine the effective data: the process data collected in the state of material passing is used as effective data, and the status of this type of data is identified.

[0030] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com