Semi-finished product traceability system for high-viscosity liquid food

A liquid food and traceability system technology, applied in food preservation, food science, weighing, etc., can solve problems such as adding other substances, valuation errors, and traceability discounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

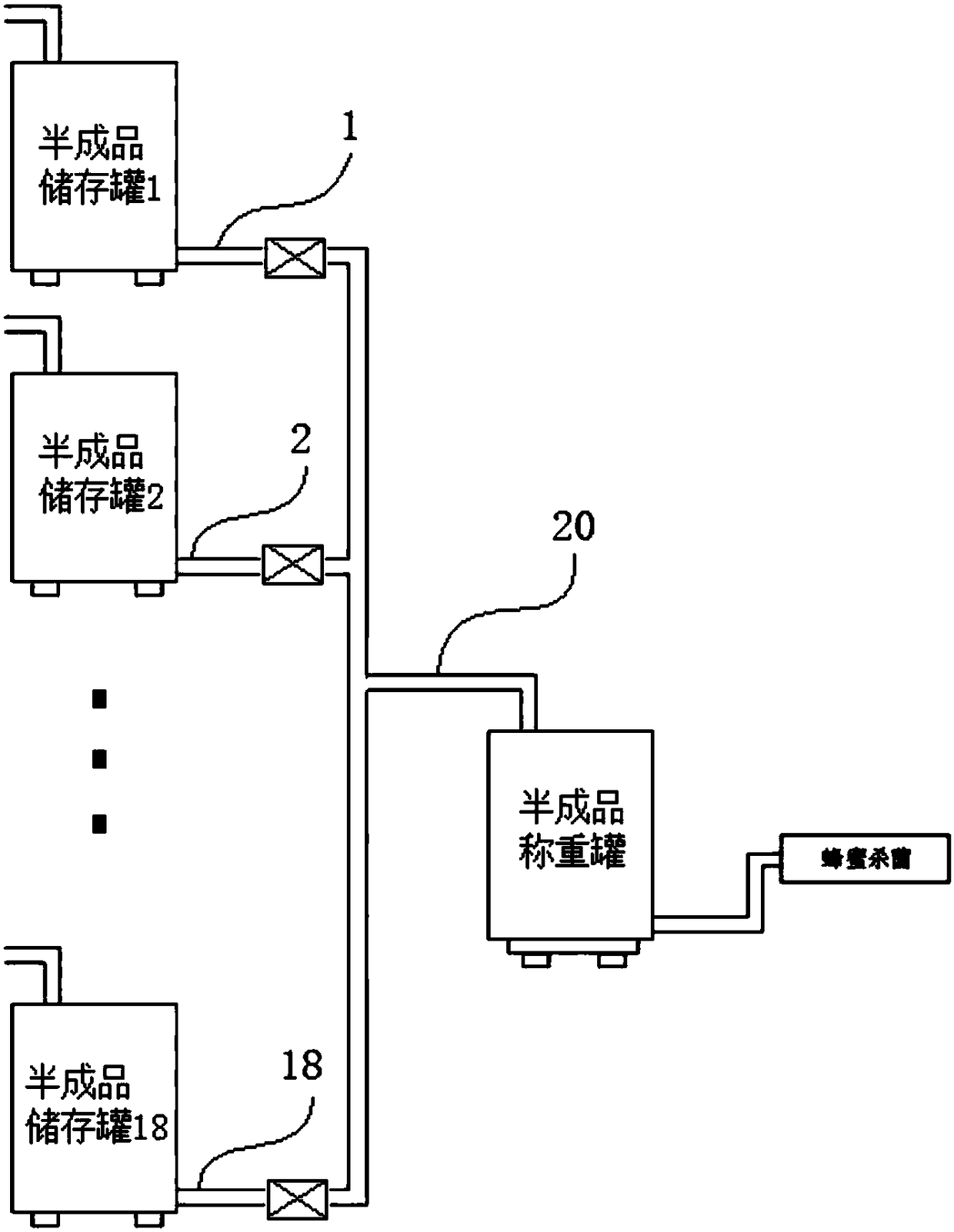

[0018] figure 1 It is a structural schematic diagram of the high-viscosity liquid food semi-finished product traceability system of the first embodiment.

[0019] In this embodiment, the traceability system for high-viscosity liquid food semi-finished products is described by taking the honey production process as an example. The production process of honey is: raw material feeding, initial filtration, precipitation, filtration, concentration, storage of semi-finished products, sterilization, filling, and packaging of finished products. Of course, in the production process after the semi-finished product, there is no factor that causes a substantial change in the weight of the product, that is to say, there is no substantial change in the weight during the process from the semi-finished product to the finished product.

[0020] Such as figure 1 As shown, a high-viscosity liquid food semi-finished product traceability system includes: 18 semi-finished product storage tanks, a...

Embodiment 2

[0040] The components and working process of the high-viscosity liquid food processing traceability system in this embodiment are the same as those in Embodiment 1. In addition, the semi-finished product batch number also records the weighing time; the daily finished product also records the production time of the finished product; according to the starting time of the semi-finished weighing tank (after the weighing is completed, the semi-finished product of the semi-finished weighing tank is sent to the honey sterilization device Start discharging time) and end discharging time (the time when all the semi-finished products of the semi-finished weighing tank are output), calculate the batch number of the semi-finished product corresponding to the finished product production time.

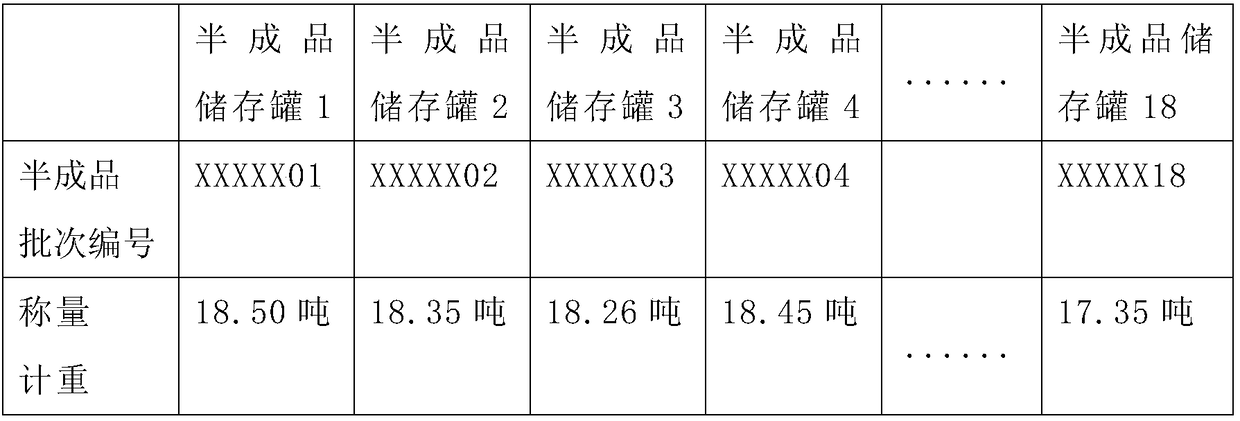

[0041] table 5

[0042]

[0043] Table 6

[0044] X day finished product time period

[0045]If the semi-finished weighing tank starts to discharge, it takes 2 hours from the start of ...

Embodiment 3

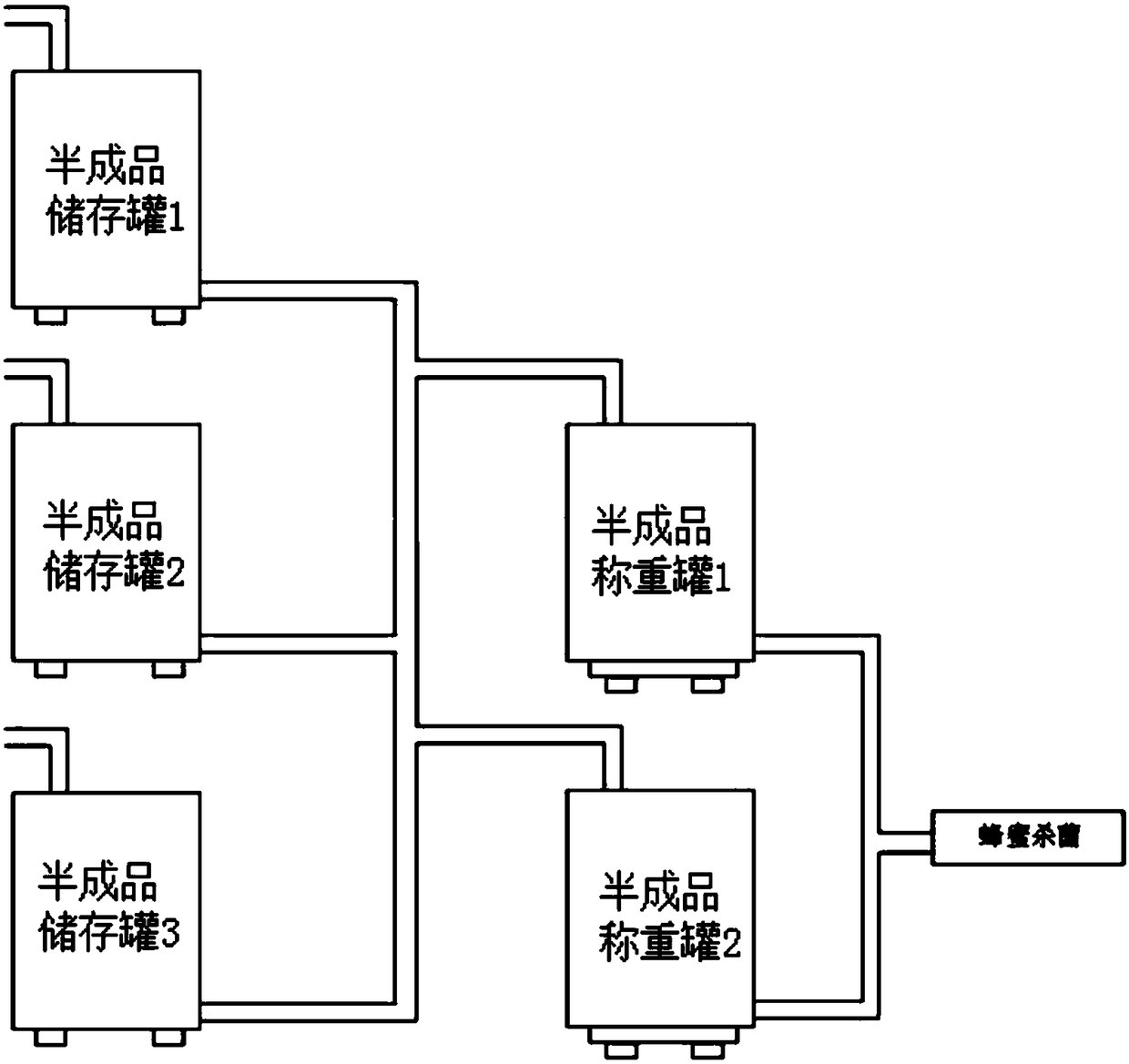

[0047] figure 2 It is a structural schematic diagram of the high-viscosity liquid food semi-finished product traceability system of the third embodiment.

[0048] Such as figure 2 As shown, in this embodiment, the high-viscosity liquid food semi-finished product traceability system includes: 3 semi-finished product storage tanks, 2 semi-finished product weighing tanks and subsequent production equipment. The main working process is the same as that of Embodiment 1, and will not be repeated. narrative.

[0049] In this embodiment, multiple weighing tanks for semi-finished products are set up mainly to avoid that in Embodiment 1, the weighing tank cannot be weighed due to the simultaneous feeding and discharging of the weighing tank, and a single weighing tank can not realize continuous production after feeding and then discharging. . In this embodiment, the semi-finished weighing tank 1 can be fed, and the semi-finished weighing tank 2 can be discharged at the same time. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com