T-shaped LED lamp tube and implementation method thereof

An LED lamp, GND technology, applied in electrical components and other directions, can solve the problems of waste of resources, smoke, and high cost, and achieve the effect of ensuring safety and reliability and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

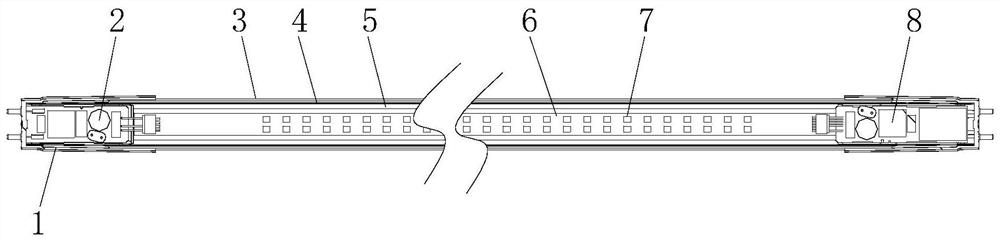

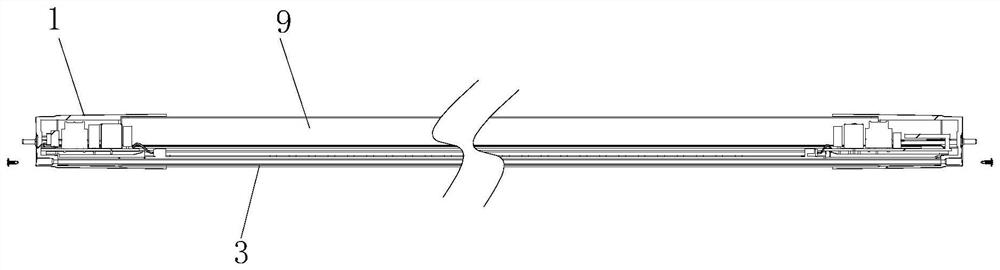

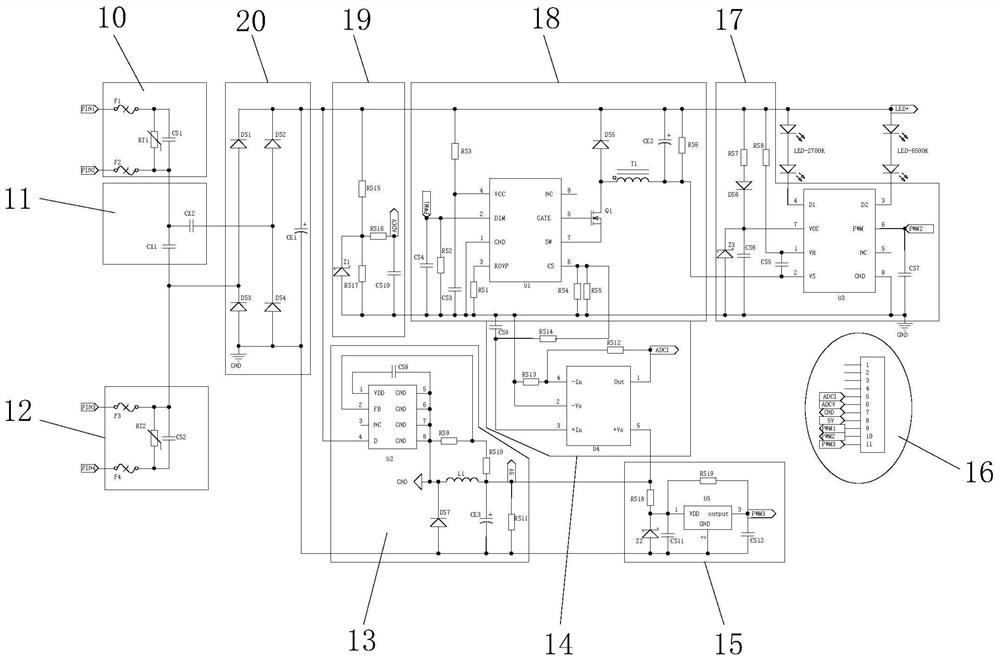

[0051] see Figure 1-15 , the present invention provides the following technical solutions: a T-shaped LED lamp tube, including a base 3, characterized in that: a heat dissipation strip 4 is arranged above the base 3, a light source substrate 6 is arranged above the heat dissipation strip 4, and a light source substrate 6 is arranged on the light source substrate 6. There are two-color LED lamp beads 7, the top of the cooling strip 4 is located on both sides of the light source substrate 6 with reflective paper 5, the top of the cooling strip 4 is located at one end of the light source substrate 6, and the first drive module 2 is installed, and the top of the cooling strip 4 is located The other end of the light source substrate 6 is provided with a second driving module 8, the first driving module 2 is electrically connected to the second driving module 8, the second driving module 8 is electrically connected to the light source substrate 6, and the two ends of the base 3 are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap