Intelligent temperature control and conductive face fabric with nano material and its preparation method and application

A nanometer and fabric technology, applied in textiles and papermaking, textile material processing, liquid/gas/steam textile material processing, etc., can solve the problems of low output, high price, unstable quality, etc., and achieve high electrothermal conversion rate, Low overall cost and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

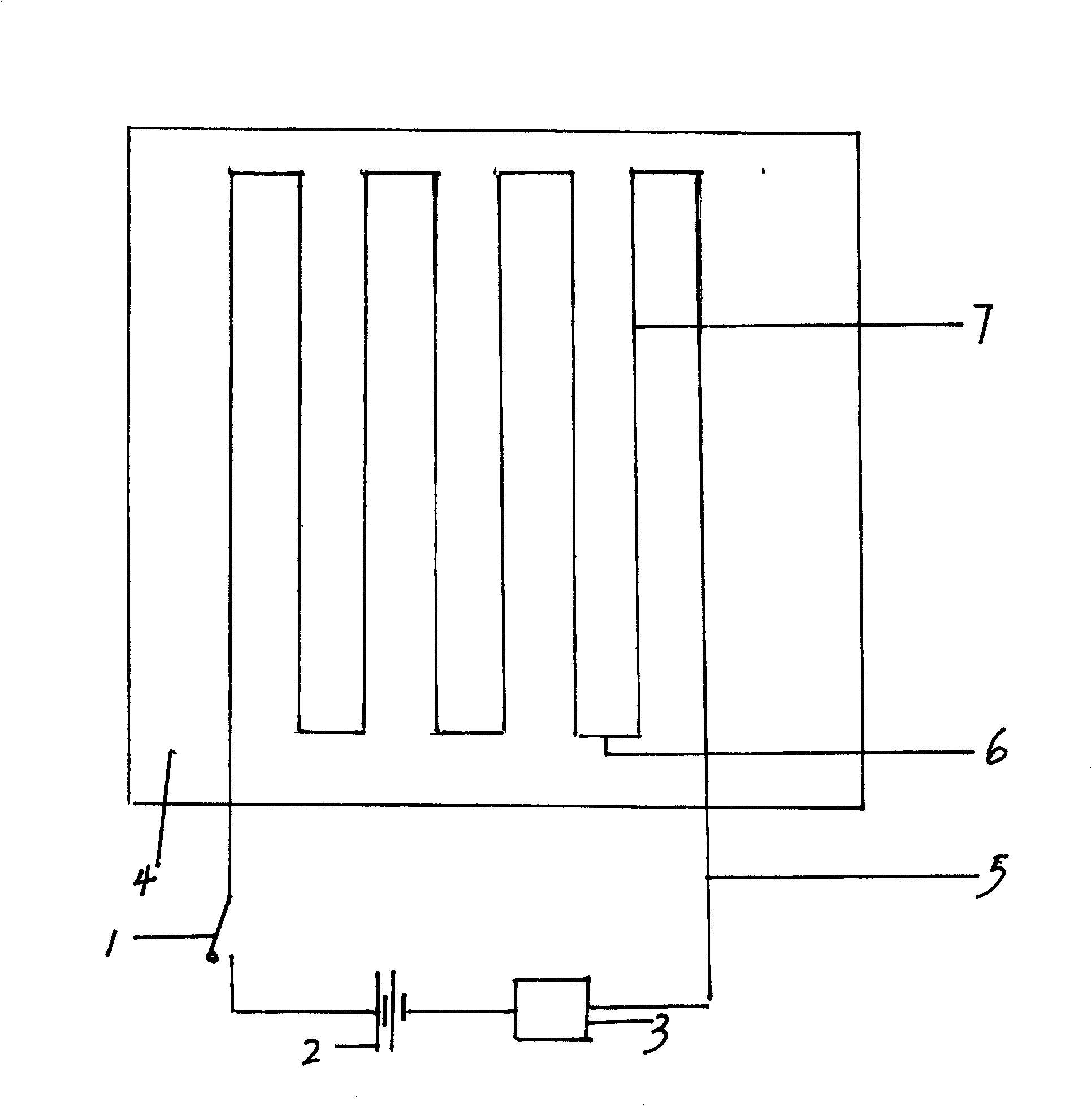

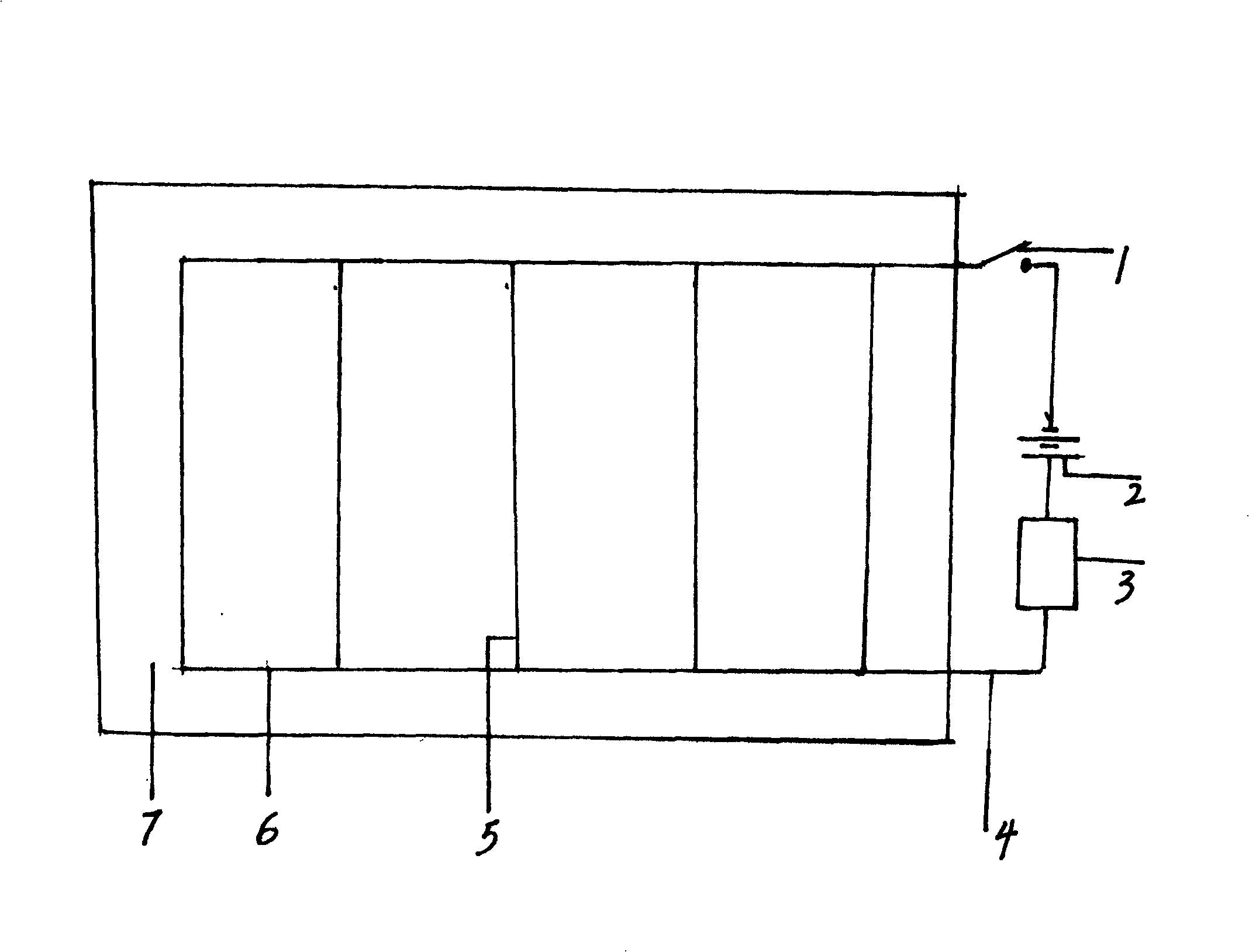

Image

Examples

Embodiment 1

[0028] (1) Silver-plated copper conductive wire is added to the conductive fabric

[0029] 12s yarn made of pure cotton or cotton and chemical fiber blended, fabric 400g / m 2 It is required that the yarn has no impurities and foreign matter, no oil stain and damp deterioration; the silver-plated copper conductive wire adopts a diameter of 0.10mm and a tensile strength of 300N / mm 2 . The distribution of wires in the radial direction of the fabric is 48 wires / meter, and the braided wires on the edges of each electrode are tightened to prevent the electrode wires from falling off. The distance between the electrodes is kept 1cm. The electrode connectors are stamped copper silver-plated connectors. , keep the fabric flat so as not to affect the resistance after coating.

[0030] (2) Conductive fabrics are treated with nano-temperature memory material coating padding

[0031] Nano-temperature memory material (carbon black content 5-70%) is coated by padding method. First, the con...

Embodiment 2

[0035] (1) Add tinned red copper conductive wire to the conductive fabric

[0036] 21s yarn made of pure cotton or blended with cotton and chemical fiber, fabric 240g / m 2 It is required that the yarn has no impurities and foreign matter, no oil stain and moisture deterioration; the tinned copper conductive wire adopts a diameter of 0.20mm and a tensile strength of >300N / mm 2 . The distribution of wires in the radial direction of the fabric is 300 wires / meter, and the braided wires on the edge of each electrode are tightened to prevent the electrode wires from falling off. The distance between the electrodes is 2cm. The electrode connectors are stamped copper-plated silver-plated connectors. , keep the fabric flat so as not to affect the resistance after coating.

[0037] (2) Conductive fabrics are treated with nano-temperature memory material coating padding

[0038] Nano-temperature memory material (carbon black content 5-70%) is coated by padding method. First, the conducti...

Embodiment 3

[0042] (1) Silver-plated copper conductive wire is added to the conductive fabric

[0043] 30s ply yarn made of pure cotton or cotton and chemical fiber blended, fabric 100g / m 2 It is required that the yarn has no impurities and foreign matter, no oil stain and damp deterioration; the silver-plated red copper conductive wire adopts a diameter of 0.40mm and a tensile strength> 400N / mm 2 . The distribution of wires in the fabric (radial direction) is 150 wires / m. The braided wires on the edge of each electrode are tightened to prevent the electrode wires from falling off. Keep 2cm between the electrodes. The electrode contacts are stamped copper silver-plated contacts. Vertically, keep the fabric flat so as not to affect the resistance after coating.

[0044] (2) Conductive fabrics are treated with nano-temperature memory material coating padding

[0045] Nano-temperature memory material (carbon black content 5-70%) is coated by padding method. First, the conductive fabric is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com