Electric nail polisher

A nail polisher, electric technology, applied in manicure or pedicure tools, clothing, applications, etc., can solve the problems of insufficient light, light reinforcement, adverse effects of nail polish operation, etc., to avoid misuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

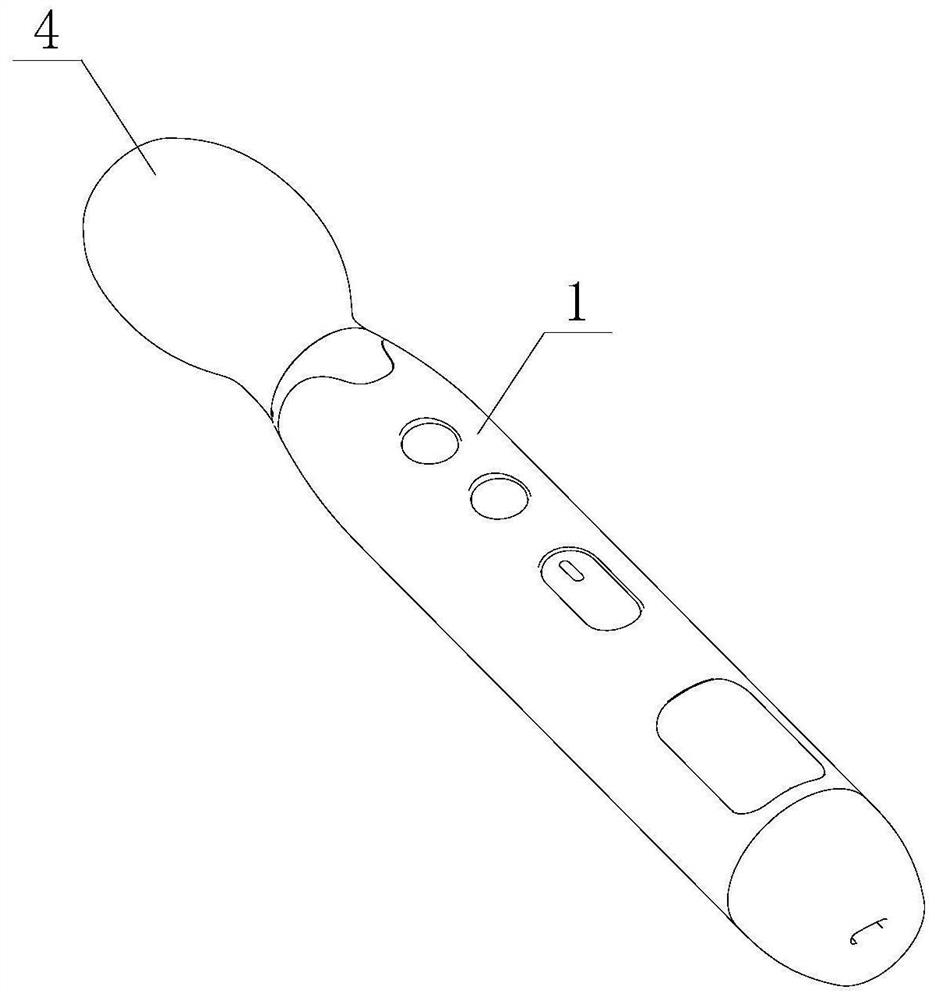

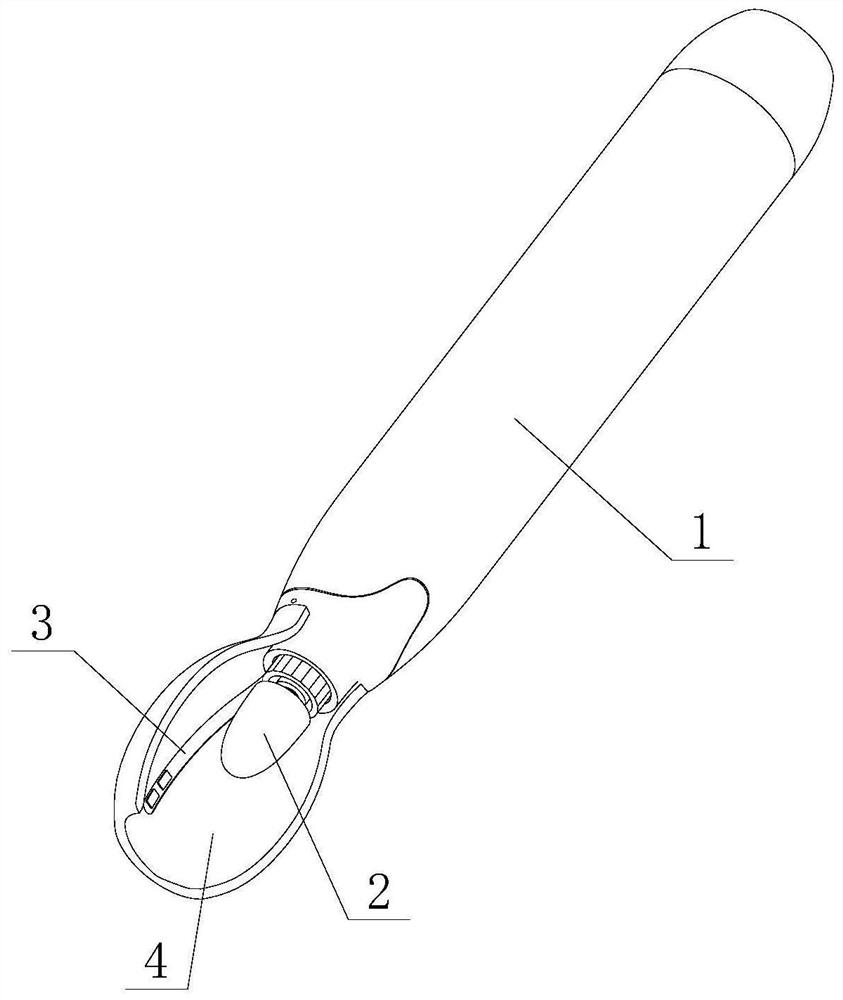

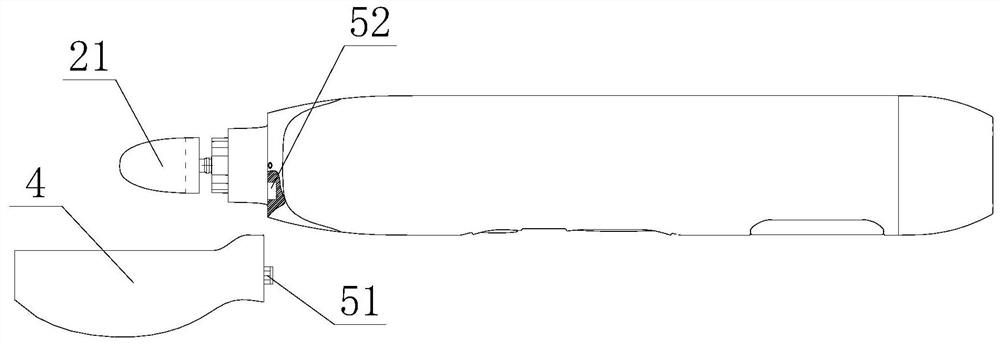

[0031] Such as Figure 1 to Figure 7 As shown, in order to facilitate understanding, taking the length direction of the nail polisher main body 1 in the drawings as the reference line, extending toward the nail mold head 2 is considered to extend toward the front end of the nail polisher main body 1, and vice versa. The extension of the bottom is considered to extend to the rear end, for example, it can be considered that the nail mold head 2 is at the front end of the nail polisher main body 1 . The electric nail grinder provided in this embodiment will be described below in conjunction with the accompanying drawings. The electric nail grinder includes a nail mold head 2 and an illuminator 3. The front end of the nail mold head 2 is provided with a grinding action part 21, and the grinding action part 21 refers to the nail. The part that plays a grinding role on the die head 2 is usually most of the front end of the nail die head 2 . The illuminator 3 is located on one side ...

Embodiment 2

[0037] such as 4 to Figure 7 As shown, the electric nail grinder provided in this embodiment includes a nail mold head 2 and an illuminator 3. The front end of the nail mold head 2 is provided with a polishing action part 21. The illuminator 3 is located on one side of the nail mold head 2. The illuminator The effective irradiation area of 3 covers the grinding action part 21. The illuminator 3 is configured as a first light strip 31, and the first light strip 31 is fixed in the middle of the transparent dustproof cover 4, preferably on one side of the polishing action part 21, and the extending direction of the first light strip 31 is in line with the transparent dustproof cover 4. The length direction of the cover 4 is consistent. Several lamp beads are arranged on the first light strip 31, and the size of the effective irradiation area of the first light strip 31 can be made It can cover or just cover the polishing part 21 of the nail mold head 2, and fixing the firs...

Embodiment 3

[0039] As shown in Figure 8, the electric nail grinder provided in this embodiment includes a nail mold head 2 and an illuminator 3, the front end of the nail mold head 2 is provided with a polishing action part 21, and the illuminator 3 is located on one side of the nail mold head 2 , the effective irradiation area of the illuminator 3 covers the polishing action portion 21 . The illuminator 3 is configured as a second light strip 32, and the second light strip 32 is fixed on the front edge of the transparent dust-proof cover 4, preferably on one side of the polishing action part 21, and the extension direction of the second light strip 32 is in line with the transparent anti-dust cover The width direction of the dust cover 4 is consistent. Several lamp beads are arranged on the second light strip 32, and the size of the effective irradiation area of the second light strip 32 can be made It can cover or just cover the polishing action part 21 of the nail mold head 2, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap