Efficient sand screening equipment for construction

A screening equipment and construction technology, applied in the fields of sieves, dispersed particle separation, cleaning methods and utensils, etc., can solve the problems of low efficiency, slow screening speed, labor cost, etc., to improve screening efficiency, improve fineness, improve Effects of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

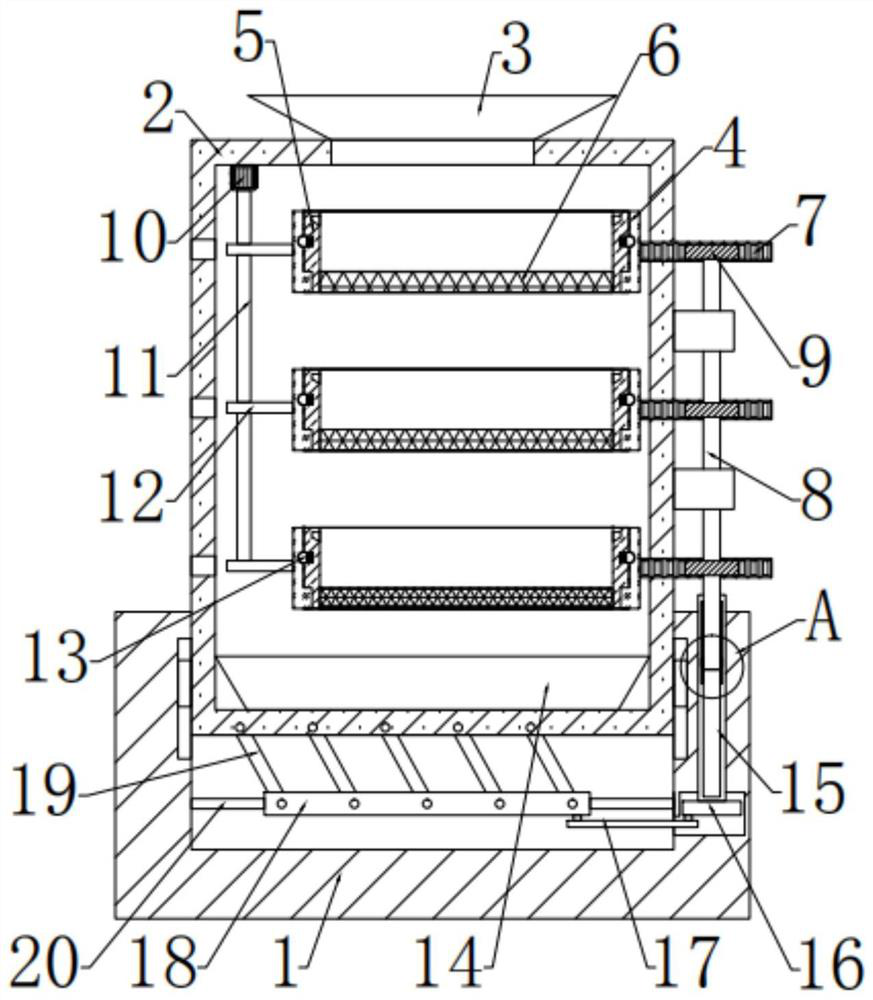

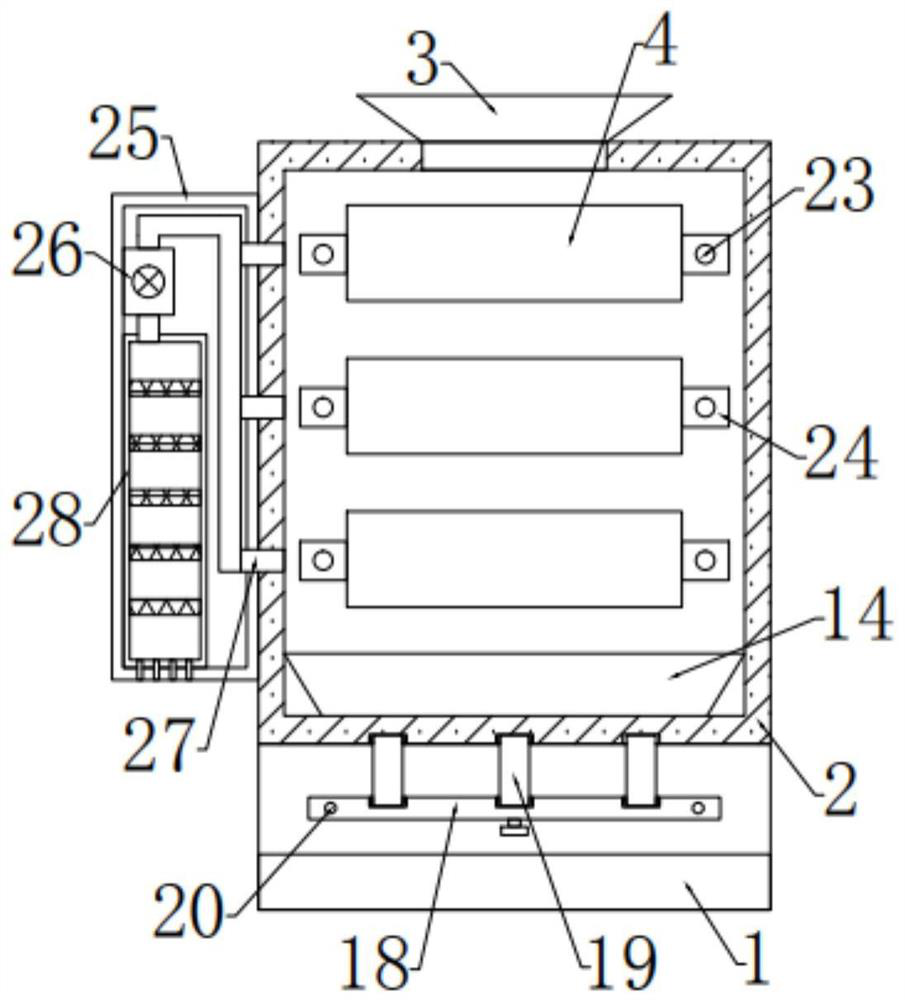

[0025] see Figure 1-4 , in the embodiment of the present invention, a high-efficiency sand screening equipment for construction, including a base 1, the inner side of the base 1 is slidingly connected with a housing 2, and the top of the housing 2 is provided with a feeding hopper 3, and the feeding A screening mechanism is arranged on the lower side of the bucket 3, and the screening mechanism is connected with a support mechanism arranged inside the base 1 through a transmission mechanism.

Embodiment 2

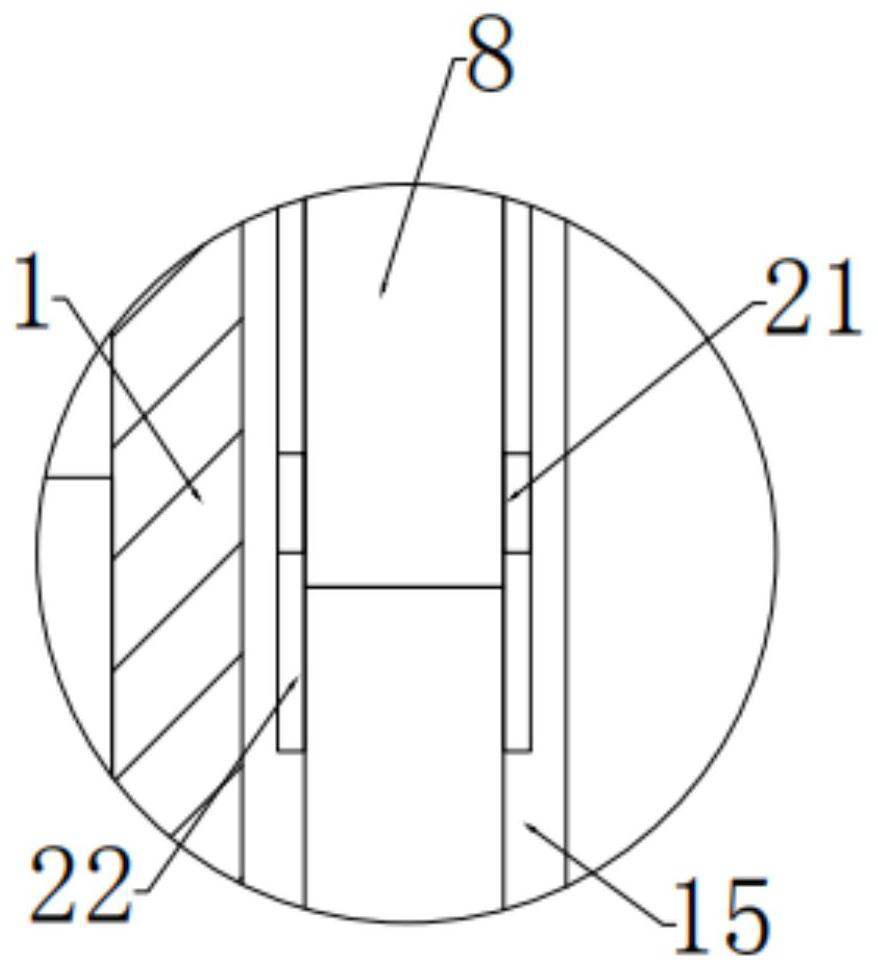

[0027] In this embodiment, the screening mechanism includes several placing frames 4 arranged inside the casing 2, and the inside of the placing frame 4 is clamped with a screen frame 5, and the front and rear sides of the placing frame 4 are fixedly connected with sliding frames. Block 24, the inner side of the slider 24 is slidably connected with a slide bar 23 fixedly connected to the housing 2, the outside of the slide bar 23 is provided with a spring, and the left side of the placement frame 4 is provided with a rotating rod 11. The rod 11 is driven by a motor 10 arranged on the inner top of the housing 2 through bolt connection, and a plurality of cams 12 are fixedly connected to the outer side of the rotating rod 11. By setting a screening mechanism, the motor 10 drives the cam 12 to rotate through the rotating rod 11, and the cam 12 And under the action of the spring, the placement frame 4 can be repeatedly moved left and right, which can improve the screening efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com